Finding the right Online Inkjet Printing Batch Coding Machine for small production lines doesn't have to break your budget. After analyzing market demands and testing various models, I've identified the most cost-effective solutions that deliver reliable performance without compromising quality. These machines excel in date coding, serialization, and variable data printing while maintaining the precision small manufacturers need. The key lies in balancing affordability with essential features like high resolution printing, automated coding capabilities, and robust maintenance systems that ensure consistent operation.

Why Small Production Lines Need Specialized Coding Solutions?

Small production lines face unique challenges that larger operations don't encounter. Limited budgets, space constraints, and the need for versatile equipment create specific requirements for coding machinery. Traditional industrial printers often exceed both budget and capacity needs, making specialized compact solutions essential.

The demand for product traceability has intensified across industries, making coding equipment mandatory rather than optional. Regulatory compliance in food, pharmaceutical, and cosmetic sectors requires precise date coding and batch identification. Small manufacturers must meet these standards while managing operational costs effectively.

Modern online inkjet printers designed for small production environments offer remarkable value. These machines deliver professional-grade marking capabilities, support multiple printing speeds, and integrate seamlessly with existing packaging lines. The evolution of thermal inkjet technology has particularly benefited smaller operations by providing affordable access to high-quality printing solutions.

Essential Selection Criteria for Budget Coding Machines

Selecting the optimal coding machine requires evaluating specific performance metrics and operational requirements. Print quality remains paramount, as illegible codes create compliance issues and customer dissatisfaction. Resolution capabilities should support barcode printing, alphanumeric characters, and graphics clearly.

Operational speed compatibility ensures smooth production flow integration. The Online Inkjet Printing Batch Coding Machine must match your line's throughput without creating bottlenecks. Ink supply systems should offer cost-effective consumption rates while maintaining consistent output quality throughout extended production runs.

Maintenance requirements directly impact total ownership costs. Simple cleaning procedures, accessible components, and reliable print head designs reduce downtime and service expenses. User-friendly interfaces enable quick setup changes and troubleshooting without specialized training.

Connectivity options allow integration with quality control systems and production management software. Modern machines support various communication protocols, enabling real-time monitoring and data collection for comprehensive product traceability.

Top Budget-Friendly Online Inkjet Coding Solutions

Faith KD486 Inkjet Printer

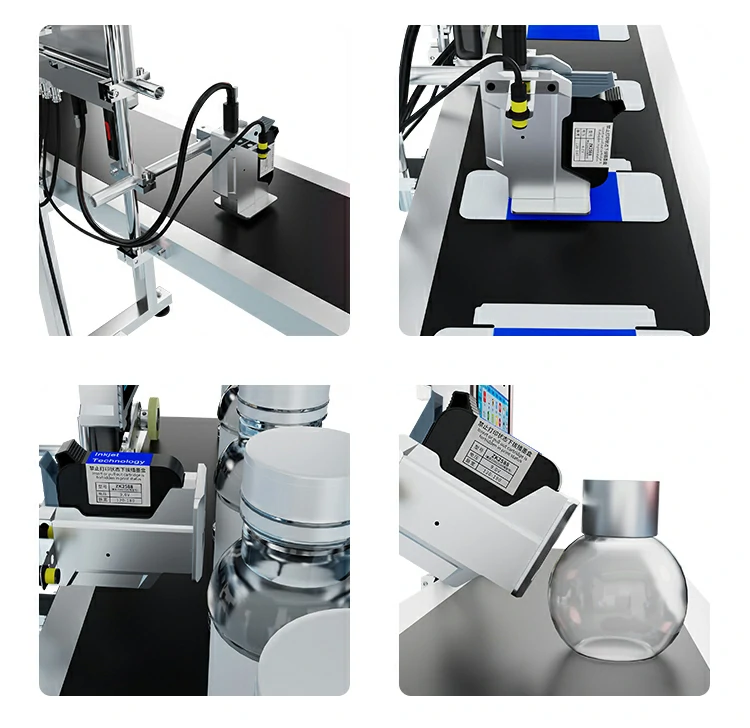

The KD486 offers outstanding performance in the TIJ printer category, designed for seamless integration with multiple production devices such as packaging machines, labeling machines, and automated lines. Its adjustable bracket design allows the printer to adapt to various product sizes, ensuring flexible deployment across diverse manufacturing scenarios.

- Print Resolution: Up to 600 DPI delivering sharp text, codes, and graphics

- Print Speed: Supports line speeds up to 110 meters per minute

- Ink Types: Compatible with water-based, solvent-based, and UV-curable inks

- Connectivity: Equipped with Ethernet, USB, and Wi-Fi for easy integration

- Power Supply: 60W 12V energy-efficient operation

- Max Print Height: 12.7 mm (0.5") suitable for standard TIJ applications

- Body Size: Compact 215mm x 35mm x 140mm footprint

- Barcode Types: Supports 1D, 2D, and QR code formats

- Character Sizes: Adjustable from 2mm to 25.4mm

- Memory Capacity: Stores 100+ message templates

The KD486’s nozzle angle can be freely adjusted, allowing precise printing even on complex curved, concave, or irregular surfaces. A photoelectric sensor ensures accurate triggering, while the 7-inch touchscreen provides real-time content preview for error-free operation. With 28 language options and six quick-drying ink colors, the printer supports global production requirements. Wireless Bluetooth editing enhances convenience, and the durable, high-adhesion ink delivers waterproof, scratch-resistant results on diverse materials including aluminum foil and plastics

Global Market Considerations and Regulatory Compliance

International markets present diverse regulatory requirements affecting Online Inkjet Printing Batch Coding Machine selection and operation. North American facilities must comply with FDA guidelines for food and pharmaceutical marking, requiring specific ink formulations and print quality standards. European markets emphasize environmental sustainability, favoring machines with recyclable components and eco-friendly ink systems.

Southeast Asian manufacturers prioritize cost-effectiveness while maintaining export quality standards. These markets often require multi-language printing capabilities and flexible character encoding to accommodate diverse product lines and destination markets.

Middle Eastern and South American markets focus on durability and reliability in challenging environmental conditions. High temperatures, humidity variations, and dust exposure demand robust equipment with enhanced environmental protection ratings.

Certification requirements vary significantly across regions, making it essential to select machines with international compliance documentation. CE marking, UL listing, and ISO certifications facilitate global market access and reduce regulatory barriers.

Smart Purchasing Recommendations and Implementation Strategy

Budget allocation should consider total cost of ownership rather than initial purchase price alone. Calculate ongoing expenses including ink consumption, maintenance supplies, and potential downtime costs. Machines with higher upfront costs often deliver superior long-term value through reduced operational expenses.

Supplier support capabilities significantly impact machine performance and longevity. Evaluate technical support availability, spare parts accessibility, and training programs offered by manufacturers. Reliable support networks prevent extended production interruptions and ensure optimal Online Inkjet Printing Batch Coding Machine utilization.

Future scalability considerations prevent premature equipment obsolescence. Select machines capable of handling increased production volumes and additional marking requirements as business grows. Modular designs allow incremental capability expansion without complete system replacement.

Integration planning ensures smooth deployment and immediate productivity benefits. Coordinate with existing quality control systems, production scheduling software, and inventory management platforms. Proper integration maximizes the investment value while streamlining operational workflows.

Industry Trends and Future Outlook

The coding machine industry continues evolving toward smarter, more connected solutions. IoT integration enables remote monitoring and predictive maintenance, reducing operational disruptions. Artificial intelligence applications optimize print quality and ink consumption automatically.

Sustainability initiatives drive development of eco-friendly ink formulations and energy-efficient designs. Manufacturers increasingly prioritize environmental responsibility while maintaining performance standards. These trends benefit small production lines through reduced operational costs and improved regulatory compliance.

Conclusion

Selecting the right Online Inkjet Printing Batch Coding Machine for small production lines requires balancing performance, reliability, and budget constraints. The featured Faith printers deliver exceptional value through innovative engineering, efficient operation, and comprehensive support services.

These machines address the core needs of small manufacturers: consistent print quality, operational efficiency, regulatory compliance, and affordable ownership costs. With proper selection and implementation, budget-friendly coding solutions can significantly enhance production capabilities while maintaining profitability.

Frequently Asked Questions

Q1: What maintenance schedule should I follow for optimal performance?

A: Most online inkjet coding machines require daily startup procedures, weekly cleaning cycles, and monthly component inspections. Faith printers include automated maintenance reminders and guided cleaning procedures to simplify routine care. Following manufacturer recommendations typically ensures 2-3 years of trouble-free operation.

Q2: Can these machines handle different ink colors for product differentiation?

A: Yes, many models support multiple ink cartridges allowing color-coded marking systems. Quick-change cartridge designs enable rapid color switching without production delays. Some machines accommodate simultaneous multi-color printing for enhanced product identification capabilities.

Q3: How do I calculate the total cost of ownership for coding equipment?

A: Include purchase price, installation costs, training expenses, ink consumption, maintenance supplies, and potential downtime costs. Factor in productivity benefits from improved efficiency and reduced manual marking labor. Most budget machines achieve payback within 12-18 months through operational savings.

Partner with Faith for Your Online Inkjet Printing Batch Coding Machine Needs

Shenyang Faith Technology stands ready to support your small production line coding requirements with proven, budget-friendly solutions. Our extensive experience serving over 200,000 customers across 126 countries demonstrates our commitment to delivering reliable, cost-effective marking equipment.

As a leading Online Inkjet Printing Batch Coding Machine supplier, we understand the unique challenges small manufacturers face. Our comprehensive product line includes continuous inkjet printers, thermal inkjet systems, and large character printers designed specifically for budget-conscious operations without compromising quality or reliability.

Our technical support team provides free consultation to help you select the optimal machine for your specific requirements. We offer customization services, comprehensive training programs, and responsive after-sales support to ensure maximum productivity and return on investment. Transform your production line marking capabilities today. Contact us at sale01@sy-faith.com for detailed product specifications, competitive pricing, and personalized recommendations tailored to your production environment.