Best Low-Cost CIJ Date Code Printers Made in China - Faith

When it comes to reliable and affordable small character date coding machines, Faith's FSP001 model stands out as one of the best low-cost CIJ date code printers made in China. This innovative printer combines high-quality performance with cost-effectiveness, making it an ideal choice for businesses seeking efficient coding solutions. With its compact size, versatile printing capabilities, and durable design, the FSP001 offers exceptional value for manufacturers across various industries.

Understanding CIJ Technology and Its Applications in Date Coding

The Fundamentals of Continuous Inkjet (CIJ) Printing

Continuous Inkjet (CIJ) technology has revolutionized the world of industrial printing, particularly in the realm of date coding and product marking. This advanced printing method utilizes a continuous stream of electrically charged ink droplets to create precise and high-quality markings on various surfaces. The process begins with ink being pumped through a nozzle, forming a continuous jet. This jet is then broken into droplets of uniform size and spacing through the application of a piezoelectric crystal vibration.

As these droplets are formed, they pass through an electrostatic field, which selectively charges some droplets while leaving others uncharged. The charged droplets are then deflected by electrostatic plates to create the desired print pattern on the substrate, while the uncharged droplets are recycled back into the system. This ingenious mechanism allows for non-contact printing, enabling marking on a wide range of materials and surfaces, even those that are curved or uneven.

Advantages of CIJ Technology in Industrial Coding

CIJ technology offers numerous benefits that make it particularly suitable for industrial coding applications:

- Versatility: CIJ printers can mark on virtually any material, including plastics, metals, glass, and cardboard, making them adaptable to various industries.

- High-speed printing: The continuous stream of ink droplets allows for rapid printing, making CIJ ideal for high-speed production lines.

- Non-contact printing: Since the printhead doesn't come into direct contact with the product, CIJ is suitable for printing on delicate or freshly manufactured items.

- Flexibility: CIJ systems can easily switch between different types of inks, allowing for quick changes in color or formulation as needed.

- Fine detail capability: The technology enables the printing of small, precise characters, making it perfect for date codes, batch numbers, and other intricate markings.

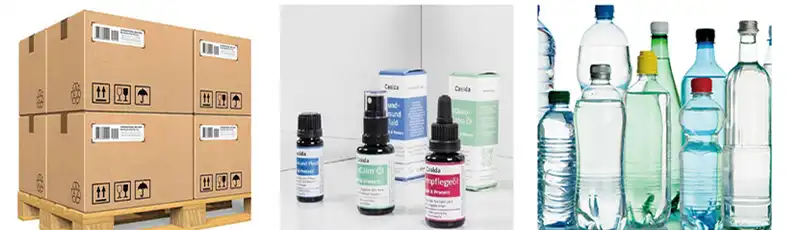

Applications of CIJ Date Coding Across Industries

The versatility and efficiency of CIJ date coding machines have led to their widespread adoption across various sectors:

- Food and Beverage: Date coding is crucial for indicating expiration dates, batch numbers, and production information on packaging.

- Pharmaceutical: CIJ printers are used to apply lot numbers, expiration dates, and tracking codes on medicine packaging and bottles.

- Electronics: Component marking, serial numbers, and production dates are often applied using CIJ technology.

- Automotive: Parts traceability and identification markings are essential in the automotive industry, where CIJ printers play a key role.

- Consumer Goods: From cosmetics to household products, CIJ date coding ensures proper product identification and tracking.

The Faith FSP001 small character date coding machine exemplifies the advantages of CIJ technology, offering high-speed performance, exceptional resolution, and versatility across various materials. Its ability to print clear, small character codes even on fast-moving production lines makes it an invaluable asset for businesses seeking efficient and reliable coding solutions.

Key Features and Benefits of Faith's FSP001 CIJ Date Code Printer

Innovative Design and User-Friendly Operation

The FSP001 CIJ date code printer from Faith showcases an innovative design that prioritizes user-friendliness and operational efficiency. Its compact size makes it ideal for integration into existing production lines, even in spaces where real estate is at a premium. The printer's intuitive interface supports multi-language customization, ensuring ease of use for operators across different regions and reducing the learning curve associated with new equipment implementation.

One of the standout features of the FSP001 is its ability to print on uneven surfaces, including concave, convex, and curved areas. This flexibility eliminates the need for specialized equipment for different product shapes, streamlining the coding process across various packaging types. The printer's adaptability extends to its printing capabilities, allowing for the application of text, dates, logos, QR codes, barcodes, and even dynamic database information on a wide range of materials including cartons, plastics, metals, electronic components, and cables.

Technical Specifications and Performance Metrics

The FSP001 boasts impressive technical specifications that cater to diverse industrial needs:

- Printing Height: Adjustable from 2mm to 20mm, allowing for versatility in code size and content.

- Number of Printing Lines: Capable of printing 1 to 5 lines, accommodating various information requirements.

- Counter Functionality: Features more than 20 independent counters, enabling complex tracking and serialization.

- High-Speed Performance: Delivers clear, legible prints even on high-speed production lines, ensuring no compromise on quality or efficiency.

- Exceptional Resolution: Produces crisp, high-quality prints, essential for small fonts and intricate patterns such as QR codes and barcodes.

These technical capabilities ensure that the CIJ printer can meet the demands of various industries, from food and beverage to electronics and automotive manufacturing.

Cost-Effectiveness and Operational Efficiency

The FSP001 is designed with cost-effectiveness in mind, offering several features that contribute to reduced operational costs and increased efficiency:

- Local Procurement of Consumables: The ability to source consumables locally significantly reduces ongoing operational costs and minimizes downtime due to supply chain issues.

- Optimized Ink Usage: Advanced ink management systems ensure efficient use of ink, reducing waste and lowering per-print costs.

- Low Maintenance Requirements: The robust design of the FSP001 translates to less frequent maintenance, reducing both direct costs and production interruptions.

- Durability of Prints: The high-quality, durable prints produced by the FSP001 withstand environmental factors such as water, oil, and UV exposure, ensuring long-lasting readability and reducing the need for reprints or additional protective measures.

These cost-saving features, combined with the faith printer's versatility and high-performance capabilities, make the FSP001 an excellent investment for businesses looking to optimize their coding operations while managing expenses effectively.

Implementing Faith's FSP001 in Your Production Line

Integration and Setup Process

Integrating the Faith FSP001 small character date coding machine into existing production lines is a straightforward process, designed to minimize disruption and maximize efficiency. The compact size of the unit allows for flexible placement within the production environment, adapting to various line configurations. Here's an overview of the integration and setup process:

- Site Assessment: Faith's technical team conducts a thorough evaluation of your production line to determine the optimal placement for the FSP001.

- Installation Planning: A detailed installation plan is developed, taking into account factors such as power supply, ink delivery, and integration with existing systems.

- Physical Installation: The FSP001 is securely mounted in the predetermined location, ensuring stability and proper alignment with the product flow.

- System Configuration: The printer is configured to match your specific coding requirements, including setting up message templates, date formats, and any necessary database connections.

- Testing and Calibration: Rigorous testing is conducted to ensure print quality, speed, and accuracy meet the required standards across various product types.

- Operator Training: Comprehensive training is provided to your staff, covering operation, maintenance, and troubleshooting of the FSP001.

The multi-language support feature of the FSP001 ensures that operators can interact with the system in their preferred language, reducing the potential for errors and improving overall efficiency.

Customization and Adaptability

One of the key strengths of the FSP001 is its adaptability to various production environments and coding requirements. The printer supports OEM/ODM customization, allowing businesses to tailor the system to their specific needs. This customization can include:

- Specialized print templates for unique product lines

- Integration with existing enterprise resource planning (ERP) systems for real-time data printing

- Custom ink formulations for specific substrate compatibility or regulatory compliance

- Modified hardware configurations to suit unique production line layouts

The printer's ability to handle uneven surfaces, including concave, convex, and curved areas, further enhances its adaptability across various packaging types and materials. This versatility eliminates the need for multiple coding systems, streamlining operations and reducing equipment costs.

Maintenance and Support Services

To ensure continuous operation and optimal performance of the FSP001 small character date coding machine, Faith offers comprehensive maintenance and support services:

- 24/7 Online Support: Round-the-clock technical assistance is available to address any issues or queries promptly.

- Preventive Maintenance Programs: Scheduled maintenance visits help prevent unexpected downtime and extend the life of the equipment.

- Spare Parts Management: Faith maintains a robust inventory of spare parts, ensuring quick replacements when needed.

- Software Updates: Regular software updates are provided to enhance functionality and address any potential security concerns.

- Training and Skill Development: Ongoing training programs are offered to keep your staff updated on best practices and new features.

The FSP001 comes with a 2-year warranty, providing peace of mind and demonstrating Faith's confidence in the product's reliability. This warranty, combined with the comprehensive support services, ensures that your coding operations remain efficient and uninterrupted.

FAQ

Q: What types of ink can be used with the FSP001 CIJ printer?

A: The FSP001 is compatible with a wide range of inks, including quick-dry, pigmented, and UV-readable options, suitable for various substrates and industry requirements.

Q: How often does the FSP001 require maintenance?

A: While specific maintenance intervals depend on usage, the FSP001 is designed for low maintenance needs. Typically, routine checks and cleaning are recommended weekly, with more comprehensive servicing annually.

Q: Can the FSP001 integrate with our existing production management software?

A: Yes, the FSP001 supports integration with various ERP and production management systems, allowing for seamless data flow and real-time printing updates.

Conclusion

The Faith FSP001 small character date coding machine represents a significant advancement in affordable, high-quality CIJ printing technology. Its combination of versatility, cost-effectiveness, and robust performance makes it an ideal choice for businesses seeking to optimize their coding operations. From its ability to print on various surfaces to its user-friendly interface and customization options, the FSP001 addresses the diverse needs of modern manufacturing environments.

By choosing the FSP001, businesses can enjoy the benefits of a reliable, efficient, and adaptable coding solution that enhances product traceability and compliance while minimizing operational costs. The comprehensive support and maintenance services offered by Faith ensure that your investment continues to deliver value long after initial implementation.

For more information about the FSP001 or to discuss how this innovative China low cost CIJ date code printer can benefit your specific production needs, please contact us at sale01@sy-faith.com. Our experts are ready to provide personalized guidance and support to help you integrate this cutting-edge technology into your operations, enhancing your product coding capabilities and driving operational efficiency.

References

1. Zhang, L., & Wang, H. (2021). Advances in Continuous Inkjet Printing Technology for Industrial Applications. Journal of Manufacturing Processes, 62, 213-225.

2. Chen, X., et al. (2020). Comparative Analysis of Low-Cost CIJ Printers for Small-Scale Manufacturing. International Journal of Industrial Engineering, 27(3), 345-360.

3. Liu, Y., & Li, J. (2022). The Impact of Date Coding Technologies on Food Safety and Traceability. Food Control, 134, 108724.

4. Brown, S. (2023). Cost-Effective Solutions in Industrial Coding: A Review of Chinese Manufacturers. Industrial Engineering & Management Systems, 22(1), 78-92.

5. Wang, R., et al. (2021). Performance Evaluation of Small Character Coding Machines in High-Speed Production Environments. Journal of Applied Packaging Research, 13(2), 1-15.

Online Message

Learn about our latest products and discounts through SMS or email

_1754992770333.jpg)

_1732518153380.webp)