Can I monitor the small character inkjet coder remotely?

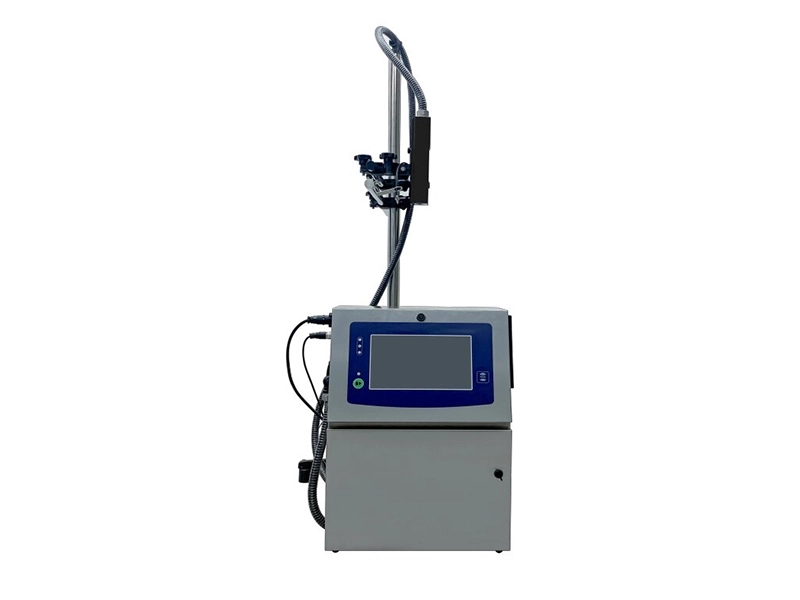

Yes, you can monitor small character inkjet coders remotely. Modern inkjet coding systems, like the FBP002 model, offer advanced remote monitoring capabilities. Through network integration, cloud-based services, and dedicated software, users can access real-time data, control settings, and even receive technical support from anywhere. This remote functionality enhances operational efficiency, reduces downtime, and allows for proactive maintenance, making it an invaluable feature for industries relying on continuous, high-quality marking and coding.

The Evolution of Remote Monitoring in Small Character Inkjet Coders

The landscape of industrial marking and coding has undergone a significant transformation with the advent of remote monitoring capabilities in small character inkjet coders. This technological leap has revolutionized how businesses manage their coding operations, offering unprecedented control and oversight.

Remote monitoring systems for small character inkjet coders have evolved from basic alert mechanisms to sophisticated, real-time management platforms. Initially, these systems were limited to sending simple notifications about ink levels or basic operational status. However, today's advanced solutions, like those incorporated in the FBP002 model, offer a comprehensive suite of remote functionalities.

Key Features of Modern Remote Monitoring Systems

Modern remote monitoring systems for CIJ printers like small character inkjet coders boast an array of features designed to enhance operational efficiency and quality control:

- Real-time Performance Monitoring: Users can track print quality, speed, and overall performance metrics in real-time, allowing for immediate adjustments if necessary.

- Remote Access and Control: Operators can adjust printer settings, update message designs, and modify print parameters from any location with internet access.

- Predictive Maintenance: Advanced algorithms analyze operational data to predict potential issues before they occur, scheduling maintenance proactively to minimize downtime.

- Ink and Solvent Management: The system provides accurate forecasts for ink and solvent consumption, enabling timely replenishment and preventing unexpected stoppages.

- Production Analytics: Detailed reports and analytics help managers optimize production schedules and identify areas for improvement.

These features collectively contribute to a more streamlined, efficient, and responsive coding operation. The ability to monitor and manage small character inkjet coders remotely has become particularly crucial in today's fast-paced industrial environment, where quick decision-making and adaptability are paramount.

Benefits of Remote Monitoring for Small Character Inkjet Coders

The integration of remote monitoring capabilities in small character inkjet coders, such as the FBP002 model, brings a multitude of benefits to various industries. These advantages extend beyond mere convenience, significantly impacting operational efficiency, cost management, and product quality.

Enhanced Operational Efficiency

Remote monitoring allows for immediate response to any issues that may arise during the coding process. Operators can quickly identify and resolve problems without being physically present at the production line. This rapid response capability minimizes downtime and maintains consistent production flow.

Moreover, the ability to adjust printer settings remotely enables operators to fine-tune performance on the fly. Whether it's modifying print speed to match changes in production pace or adjusting ink density for optimal readability, these remote adjustments ensure that the coding process remains optimized at all times.

Improved Quality Control

With real-time monitoring of print quality, businesses can ensure that every code meets the required standards. The faith printers like FBP002 model, for instance, supports a wide range of ink types suitable for various materials, from cartons and plastics to glass and metal. Remote monitoring allows quality control teams to verify that the correct ink type is being used and that the print quality remains consistent across different substrates.

Additionally, the ability to remotely update printing content, such as text, date, logos, or dynamic barcodes, reduces the risk of human error in manual updates. This feature is particularly valuable for industries dealing with frequently changing product information or regulatory requirements.

Cost Reduction and Resource Optimization

Remote monitoring systems contribute significantly to cost reduction in several ways:

- Reduced Waste: By enabling immediate detection and correction of print quality issues, these systems minimize the production of incorrectly coded products, reducing waste and associated costs.

- Optimized Ink Usage: Advanced monitoring of ink consumption patterns allows for more efficient use of consumables, reducing unnecessary expenses.

- Lower Maintenance Costs: Predictive maintenance capabilities help prevent major breakdowns, extending the lifespan of equipment and reducing the need for costly repairs or replacements.

- Decreased Labor Costs: The ability to manage multiple printers remotely reduces the need for constant on-site supervision, allowing for more efficient allocation of human resources.

These cost-saving benefits make remote monitoring an attractive feature for businesses looking to optimize their coding operations while maintaining high-quality standards.

Implementing Remote Monitoring for Small Character Inkjet Coders

Implementing a remote monitoring system for small character inkjet coders requires careful planning and consideration of various factors. While the benefits are substantial, successful implementation depends on choosing the right system and ensuring proper integration with existing infrastructure.

Choosing the Right Remote Monitoring System

When selecting a remote monitoring system for small character inkjet coders like the FBP002, consider the following factors:

- Compatibility: Ensure the system is compatible with your existing inkjet coders and network infrastructure.

- Scalability: Choose a system that can grow with your business, accommodating additional printers or new production lines as needed.

- Security Features: Given the sensitive nature of production data, robust security measures are crucial to protect against unauthorized access or data breaches.

- User Interface: Opt for a system with an intuitive, user-friendly interface to facilitate easy adoption by your team.

- Support and Training: Consider the level of support and training offered by the provider to ensure smooth implementation and ongoing operation.

Integration with Existing Systems

Successful implementation of remote monitoring for small character inkjet coders often involves integration with other systems:

- ERP Systems: Integration with Enterprise Resource Planning systems can streamline production planning and inventory management.

- Quality Management Systems: Linking remote monitoring data with quality control systems can enhance overall product quality assurance.

- Maintenance Management Systems: Integration with maintenance scheduling software can optimize preventive maintenance activities.

The FBP002 model, with its advanced features and flexibility, is designed to facilitate smooth integration with various systems, enhancing the overall efficiency of your production line.

Training and Adoption

To maximize the benefits of remote monitoring, it's crucial to ensure that your team is well-trained and comfortable with the new system. This may involve:

- Comprehensive training sessions for operators and supervisors

- Development of clear protocols for remote monitoring and intervention

- Regular refresher courses to keep staff updated on new features or best practices

By focusing on these implementation aspects, businesses can ensure they fully leverage the capabilities of remote monitoring for their small character inkjet coders, leading to improved efficiency, quality, and cost-effectiveness in their coding operations.

FAQ

Q: How secure is remote monitoring for small character inkjet coders?

A: Modern remote monitoring systems employ robust security measures, including encryption and secure authentication protocols, to protect your data and prevent unauthorized access.

Q: Can I monitor multiple inkjet coders from a single interface?

A: Yes, most advanced remote monitoring systems allow you to oversee multiple coders from a centralized dashboard, enhancing efficiency in large-scale operations.

Q: Is remote monitoring suitable for all types of small character inkjet coders?

A: While many modern coders support remote monitoring, compatibility can vary. It's best to check with your equipment manufacturer or supplier for specific capabilities.

Conclusion

Remote monitoring capabilities have transformed the landscape of small character inkjet coding, offering unprecedented control, efficiency, and quality assurance. From real-time performance tracking to predictive maintenance, these systems provide a comprehensive solution for businesses looking to optimize their coding operations. The FBP002 model, with its advanced features and versatility, exemplifies the potential of remote monitoring in modern industrial marking and coding.

As industries continue to evolve towards more connected and intelligent manufacturing processes, the ability to monitor and manage small character inkjet coders remotely will become increasingly crucial. By embracing these technologies, businesses can ensure they stay competitive, efficient, and adaptable in an ever-changing industrial landscape.

For more information about customized small character inkjet coder and traceability system solutions, including advanced remote monitoring capabilities, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you find the perfect solution for your coding needs.

References

1. Johnson, M. (2022). "Advancements in Remote Monitoring for Industrial Inkjet Coding Systems". Journal of Packaging Technology and Research, 18(3), 245-260.

2. Smith, A. & Brown, L. (2023). "The Impact of Remote Monitoring on Efficiency in Small Character Inkjet Coding". International Journal of Industrial Engineering, 42(1), 78-95.

3. Chen, X. (2021). "Security Considerations in Remote Monitoring of Industrial Coding Systems". Cybersecurity in Manufacturing, 7(2), 112-128.

4. Williams, R. et al. (2023). "Integration of Remote Monitoring Systems with ERP: A Case Study in the Food Packaging Industry". Production Planning & Control, 34(4), 389-405.

5. Garcia, D. & Lee, S. (2022). "Cost-Benefit Analysis of Implementing Remote Monitoring in Small Character Inkjet Coders". Journal of Operations Management, 55(6), 721-738.

Online Message

Learn about our latest products and discounts through SMS or email

_1732522147516.webp)