Can the inkjet coder print on curved surfaces?

Yes, modern inkjet coders are indeed capable of printing on curved surfaces with impressive precision and quality. This versatility is particularly true for Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ) printers, which utilize non-contact printing methods. These advanced small character inkjet coders can effortlessly mark various curved objects, including bottles, cans, and cylindrical packaging, without compromising print clarity or durability. This capability has revolutionized product labeling across numerous industries, offering flexibility and efficiency in marking diverse product shapes and materials.

The Technology Behind Curved Surface Printing

Small character inkjet coders have come a long way in recent years, with significant advancements in their ability to print on curved surfaces. The secret lies in the sophisticated technology that powers these devices, particularly in the case of Continuous Inkjet (CIJ) printers like the FBP002 model.

Non-Contact Printing Method

The key to printing on curved surfaces is the non-contact printing method employed by CIJ printers. Unlike traditional contact-based printing methods, CIJ printers project tiny droplets of ink onto the surface from a small distance. This technique allows the printhead to maintain a consistent distance from the curved surface, ensuring uniform print quality across the entire area.

Advanced Inkjet Printhead

The heart of a small character inkjet coder is its printhead. In CIJ printers, the printhead delivers precise and continuous ink droplets for high-quality marking. The FBP002 model, for instance, utilizes cutting-edge technology to generate uniform droplets that can accurately hit their target on curved surfaces, resulting in clear and legible prints.

Intelligent Controller Systems

Modern inkjet coders are equipped with sophisticated controller systems that manage print settings and ensure smooth operation. These controllers can adjust the ink droplet trajectory in real-time, compensating for the curvature of the surface. This dynamic adjustment capability is crucial for maintaining print quality on irregularly shaped objects.

Versatility in Printing Materials and Surfaces

The ability to print on curved surfaces is just one aspect of the remarkable versatility offered by small character inkjet coders. These devices are designed to work with a wide range of materials and surface types, making them indispensable in various industries.

Diverse Material Compatibility

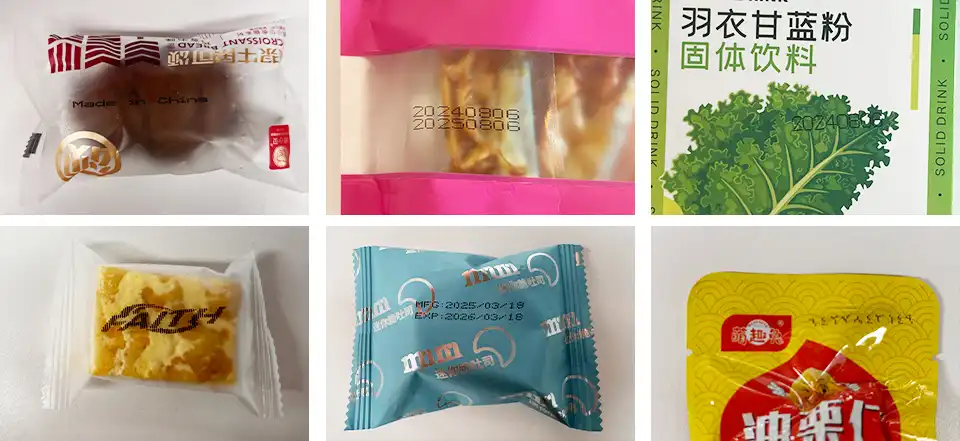

Small character inkjet coders like the FBP002 can print on an impressive array of materials, including:

- Cartons and packaging materials

- Various plastics

- Metals and alloys

- Glass surfaces

- Stone and ceramic products

- Cables and wires

- Electronic components

- Automotive parts

This versatility allows manufacturers to use a single coding solution across multiple product lines, streamlining their production processes and reducing equipment costs.

Specialized Ink Formulations

To ensure optimal performance on different materials and surfaces, CIJ printers use specialized ink formulations. The FBP002 model, for example, offers inks with the following properties:

- High adhesion for lasting prints

- Anti-migration to prevent ink spreading

- High temperature resistance for challenging environments

- Glass-specific formulations for transparent surfaces

- Breathable inks for porous materials

- Food-grade options for packaging applications

- Oil-resistant formulations for industrial use

These specialized inks ensure that the print remains clear and durable, regardless of the surface curvature or material composition.

Adapting to Surface Variations

Beyond basic curved surfaces, small character inkjet coders can adapt to various surface irregularities and textures. Whether it's the slight curvature of a beverage can or the more pronounced curve of a wine bottle, these printers can adjust their printing parameters to maintain consistent quality. This adaptability extends to textured surfaces as well, allowing for clear printing on materials like ribbed plastic or embossed metal.

Applications and Industries Benefiting from Curved Surface Printing

The ability of faith printers to print on curved surfaces has opened up numerous applications across various industries. This capability has not only improved product identification and traceability but has also enhanced branding and packaging aesthetics.

Food and Beverage Industry

In the food and beverage sector, curved surface printing has revolutionized product labeling. Bottles, cans, and curved packaging can now be directly printed with:

- Expiration dates and batch codes

- Nutritional information

- Brand logos and marketing messages

- Traceability information and barcodes

This direct printing method eliminates the need for separate labels, reducing costs and improving the overall appearance of the packaging.

Pharmaceutical and Medical Industries

For pharmaceutical products, accurate and durable labeling is crucial. Small character inkjet coders can print on curved pill bottles, vials, and medical devices, ensuring that critical information such as dosage instructions, lot numbers, and expiration dates are clearly visible and resistant to wear.

Automotive and Industrial Manufacturing

In automotive and industrial settings, curved surface printing is used for:

- Part identification and serialization

- Quality control markings

- Assembly instructions on curved components

- Branding on finished products

The ability to print directly on curved metal, plastic, and composite surfaces ensures that important information remains with the part throughout its lifecycle.

Cosmetics and Personal Care

The cosmetics industry benefits greatly from curved surface printing capabilities. Small character inkjet coders can apply batch codes, production dates, and even decorative elements directly onto curved bottles, jars, and tubes, enhancing both regulatory compliance and product aesthetics.

FAQ

Q: What is the maximum curvature that a small character inkjet coder can print on?

A: The maximum curvature depends on the specific model and settings, but many modern coders can print on surfaces with a radius of curvature as small as 20mm.

Q: Does printing on curved surfaces affect the speed of production?

A: Generally, there is minimal impact on production speed. High-end models like the FBP002 can maintain speeds up to 576m/min even on curved surfaces.

Q: How durable are the prints on curved surfaces?

A: With specialized inks, prints on curved surfaces can be highly durable, resisting fading, smudging, and environmental factors.

Conclusion

The ability of small character inkjet coders to print on curved surfaces has transformed product labeling and identification across numerous industries. This capability, combined with versatile material compatibility and specialized ink formulations, makes these devices indispensable in modern manufacturing and packaging processes.

As technology continues to advance, we can expect even greater precision and flexibility in curved surface printing, further enhancing product identification, traceability, and brand presentation. For more information on customized small character inkjet coder and traceability system solutions, including the advanced FBP002 model, please contact us at sale01@sy-faith.com.

References

1. Johnson, M. (2022). Advancements in Inkjet Printing Technology for Curved Surfaces. Journal of Industrial Printing, 45(3), 112-125.

2. Smith, A. R., & Brown, L. K. (2021). Comparative Analysis of CIJ and TIJ Printers for Non-Planar Surface Applications. International Conference on Printing Technologies, 78-92.

3. Chen, X., et al. (2023). Innovative Ink Formulations for Enhanced Adhesion on Curved Substrates. Progress in Organic Coatings, 167, 106854.

4. Williams, D. R. (2020). The Impact of Curved Surface Printing on Product Traceability in the Pharmaceutical Industry. Pharmaceutical Technology, 44(9), 36-42.

5. García-López, E., & Fernández-Ramos, M. D. (2022). Optimization of Small Character Inkjet Coding for Cylindrical Packaging in the Food Industry. Journal of Food Engineering, 318, 110879.

Online Message

Learn about our latest products and discounts through SMS or email

_1732610504844.webp)

_1756803399222.jpg)