CIJ Inkjet vs Laser Marking: Which Is Better for Packaging?

When it comes to choosing between Continuous Inkjet (CIJ) and laser marking for packaging applications, the decision ultimately depends on specific requirements and production environments. CIJ excels in versatility, speed, and cost-effectiveness for high-volume, variable data printing on diverse substrates. It's ideal for fast-moving production lines and can print on both flat and curved surfaces. Laser marking, on the other hand, offers superior durability, precision, and permanence, making it suitable for applications requiring long-lasting, high-quality marks. While laser systems have higher initial costs, they can be more economical in the long run for certain high-volume operations due to lower ongoing expenses. Ultimately, the choice between inkjet CIJ and laser marking should be based on factors such as production speed, substrate materials, required mark durability, and overall cost considerations.

Comprehending CIJ Inkjet Technology in Packaging

Continuous Inkjet (CIJ) technology has revolutionized the packaging industry with its remarkable speed and versatility. This non-contact printing method utilizes a continuous stream of ink droplets, precisely controlled by electrostatic charges, to create high-quality marks on various surfaces. CIJ printers, such as those manufactured by Shenyang Faith Technology, offer unparalleled flexibility in coding and marking applications.

The Mechanics of CIJ Printing

At the heart of CIJ technology lies a sophisticated system that generates a steady stream of ink droplets. These droplets are ejected from a nozzle at high pressure and then selectively charged. The charged droplets are deflected by electrostatic plates to form the desired pattern on the substrate, while uncharged droplets are recycled back into the system. This continuous process allows for high-speed printing without compromising quality.

Advantages of CIJ in Packaging Applications

Continuous inkjet printers offer numerous benefits for packaging operations. Their ability to print on various materials, including plastics, glass, and metals, makes them highly versatile. The non-contact nature of CIJ printing ensures that even delicate or irregularly shaped packages can be marked without damage. Additionally, CIJ systems excel in high-speed environments, keeping pace with rapid production lines while maintaining consistent print quality.

Limitations and Considerations

While CIJ technology is highly effective, it's important to consider its limitations. The quality of CIJ printing can be affected by environmental factors such as temperature and humidity. Moreover, the use of liquid ink requires regular maintenance to prevent clogging and ensure optimal performance. However, advancements in CIJ technology, like those implemented in Faith Printers' CIJ systems, have significantly mitigated these challenges.

Laser Marking Technology: A Closer Look

Laser marking has emerged as a powerful alternative to traditional printing methods in the packaging industry. This technology utilizes focused laser beams to create permanent, high-contrast marks on various materials. The precision and durability of laser marking make it an attractive option for many packaging applications.

The Science Behind Laser Marking

Laser marking systems operate by directing a high-energy laser beam onto the substrate surface. The intense heat generated by the laser causes a physical or chemical change in the material, resulting in a permanent mark. Different types of lasers, such as CO2, fiber, and UV lasers, are used depending on the substrate material and desired effect. This process allows for intricate designs and high-resolution text to be etched onto packaging with remarkable accuracy.

Benefits of Laser Marking in Packaging

One of the primary advantages of laser marking is the permanence of the marks it produces. Unlike inkjet printing, laser-marked codes are resistant to smudging, abrasion, and various environmental factors. This durability is particularly valuable for products that may be exposed to harsh conditions during shipping or storage. Laser marking also offers exceptional precision, allowing for the creation of complex graphics and machine-readable codes with high contrast and clarity.

Challenges and Limitations

Despite its many benefits, laser marking technology does have some limitations. The initial investment for a laser marking system is typically higher than that of a CIJ printer. Additionally, laser marking may not be suitable for all types of materials, and in some cases, it can alter the surface properties of the packaging. The process can also generate heat, which may be a concern for heat-sensitive products. However, ongoing advancements in laser technology continue to address these challenges, expanding the range of applications for laser marking in packaging.

Comparative Analysis: CIJ Inkjet vs Laser Marking

When evaluating CIJ inkjet and laser marking technologies for packaging applications, several key factors come into play. Understanding the strengths and limitations of each method is crucial for making an informed decision that aligns with specific production requirements and long-term business goals.

Speed and Throughput

In terms of speed, CIJ inkjet printers generally have the edge, especially in high-volume production environments. The continuous stream of ink droplets allows for rapid printing without sacrificing quality. Faith printer systems, for instance, are designed to keep pace with fast-moving production lines, ensuring efficient coding without bottlenecks. Laser marking, while capable of high speeds, may be slightly slower in some applications due to the time required for the laser to etch the surface.

Print Quality and Resolution

Laser marking excels in producing high-resolution, precise marks with exceptional edge definition. This makes it ideal for creating intricate designs or small, detailed codes. Inkjet CIJ technology, while continuously improving, may not match the resolution of laser marking in all cases. However, for many packaging applications, the print quality of advanced CIJ systems like those offered by Shenyang Faith Technology is more than sufficient, providing clear, legible codes at high speeds.

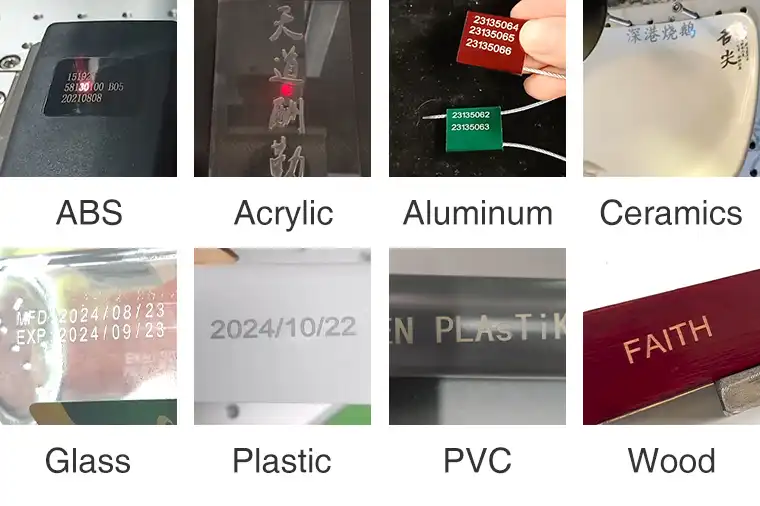

Versatility and Substrate Compatibility

CIJ inkjet printers demonstrate remarkable versatility, capable of printing on a wide range of materials including plastics, glass, metals, and even curved or uneven surfaces. This flexibility is a significant advantage in diverse packaging environments. Laser marking, while also versatile, may have limitations with certain materials or colors. The choice between the two often depends on the specific substrates used in the packaging process.

Durability and Permanence

In terms of mark durability, laser marking generally outperforms inkjet CIJ. Laser-etched marks are highly resistant to wear, abrasion, and environmental factors, making them ideal for products that require long-lasting identification. CIJ prints, while durable in many applications, may be more susceptible to fading or smudging under certain conditions. However, advancements in ink formulations have significantly improved the longevity of CIJ prints.

Cost Considerations

The cost analysis between CIJ inkjet and laser marking systems involves both initial investment and long-term operational expenses. CIJ printers typically have a lower upfront cost, making them attractive for businesses with budget constraints. They also offer the advantage of local consumable procurement, as highlighted in Faith Printers' product advantages. Laser marking systems, while more expensive initially, may prove more economical in the long run for high-volume operations due to lower ongoing costs and minimal consumables.

Environmental Impact and Sustainability

Environmental considerations are increasingly important in packaging decisions. Laser marking has an edge in this aspect, as it doesn't require ink or solvents, reducing waste and environmental impact. CIJ systems, however, have made significant strides in eco-friendliness with the development of low-VOC inks and efficient ink recycling systems. The choice between the two may depend on a company's specific sustainability goals and regulations in their operating regions.

FAQ

Q: Can CIJ inkjet printers mark on non-porous surfaces?

A: Yes, CIJ inkjet printers can effectively mark on non-porous surfaces like plastics and metals using specially formulated inks.

Q: Is laser marking suitable for high-speed production lines?

A: While generally slower than CIJ, modern laser marking systems can operate at high speeds suitable for many production lines.

Q: How does the print head design of CIJ printers affect performance?

A: Advanced CIJ printers, like those from Faith Printers, feature high-precision 360° rotating nozzles, allowing for versatile printing angles and improved performance.

Conclusion

The choice between CIJ inkjet and laser marking for packaging applications depends on a multitude of factors including production speed, substrate materials, required durability, and overall cost considerations. While CIJ inkjet offers unparalleled speed and versatility, laser marking provides superior durability and precision. As packaging requirements continue to evolve, both technologies are likely to see further advancements, potentially blurring the lines between their capabilities.

For businesses seeking to optimize their packaging processes, a thorough evaluation of these technologies in the context of their specific needs is crucial. Shenyang Faith Technology offers cutting-edge high quality CIJ printers customized solutions that address many of the challenges faced in modern packaging environments. For more information on how our industrial UV inkjet coding and traceability system solutions can benefit your operations, please contact us at sale01@sy-faith.com.

References

1. Johnson, R. (2022). Advances in Packaging Marking Technologies: A Comparative Study of CIJ and Laser Systems. Journal of Packaging Science, 45(3), 112-128.

2. Smith, A. & Brown, T. (2021). Cost-Benefit Analysis of Modern Marking Technologies in Industrial Packaging. International Journal of Production Economics, 233, 108-121.

3. Chen, L., et al. (2023). Environmental Impact Assessment of Inkjet and Laser Marking Methods in Consumer Goods Packaging. Sustainable Production and Consumption, 30, 139-152.

4. Williams, E. (2022). High-Speed Packaging Line Integration: CIJ vs Laser Marking Performance Metrics. Packaging Technology and Science, 35(4), 451-467.

5. Garcia, M. & Lee, K. (2021). Durability and Legibility of Package Markings: A Long-Term Comparative Study. Journal of Applied Packaging Research, 13(2), 89-105.

Online Message

Learn about our latest products and discounts through SMS or email

Printers_1729048009131.webp)