CIJ Printer Guide: Specs, Applications & Buying Tips

Continuous Inkjet (CIJ) printers have revolutionized industrial marking and coding. This comprehensive guide delves into the specifications, applications, and crucial buying considerations for CIJ printers, with a focus on faith customized CIJ printers. We'll explore the technology behind these versatile machines, their diverse applications across industries, and provide expert tips to help you choose the perfect CIJ printer for your specific needs. Whether you're new to CIJ technology or looking to upgrade your existing system, this guide will equip you with the knowledge to make an informed decision.

Understanding CIJ Printer Technology and Specifications

How CIJ Printers Work?

Continuous Inkjet (CIJ) printing technology is a marvel of modern engineering. At its core, CIJ printers operate by creating a continuous stream of ink droplets. These droplets are electrically charged and then deflected by electrostatic plates to form precise patterns on the substrate. This process allows for high-speed, non-contact printing on a wide variety of surfaces.

The faith customized CIJ printer exemplifies the pinnacle of this technology. Its modular print head design allows for easy maintenance and upgrades, while the stainless steel body ensures durability in demanding industrial environments. The IP68-rated external interface protects against dust and water ingress, making it suitable for use in challenging conditions.

Key Specifications of Modern CIJ Printers

When evaluating CIJ printers, several key specifications stand out. Print speed is a crucial factor, with top-tier models like the faith customized CIJ printer capable of achieving speeds up to 576m/min. This impressive velocity ensures that even the fastest production lines can be accommodated without compromising print quality.

Print resolution is another vital specification. CIJ printers offer a range of font options, from basic 5x6L matrices to more complex 32x32B configurations. This versatility allows for clear, legible printing of text, logos, and even intricate barcodes. The faith customized CIJ printer boasts an extensive font library, including options for both linear (L) and bold (B) characters.

Ink compatibility is a critical consideration. Modern CIJ printers, including faith customized models, support a wide array of ink types. These include high-adhesion inks for challenging surfaces, migration-resistant formulations for food packaging, and specialized inks for glass or high-temperature applications. This ink versatility ensures that CIJ printers can adapt to diverse industry requirements.

Advanced Features for Enhanced Performance

Leading CIJ printers incorporate advanced features to boost productivity and ease of use. For instance, the faith customized CIJ printer includes more than 20 independent counters, allowing for complex batch coding and serialization. This feature is invaluable in industries requiring detailed product tracking and traceability.

Environmental adaptability is another crucial feature. The best CIJ printers, including faith customized models, are designed to operate reliably in a wide range of conditions. Typical operating parameters include temperatures from 0 to 45°C and relative humidity levels between 30% and 70%. This robustness ensures consistent performance across various industrial settings.

Applications Across Industries: Versatility of CIJ Printers

Food and Beverage Industry

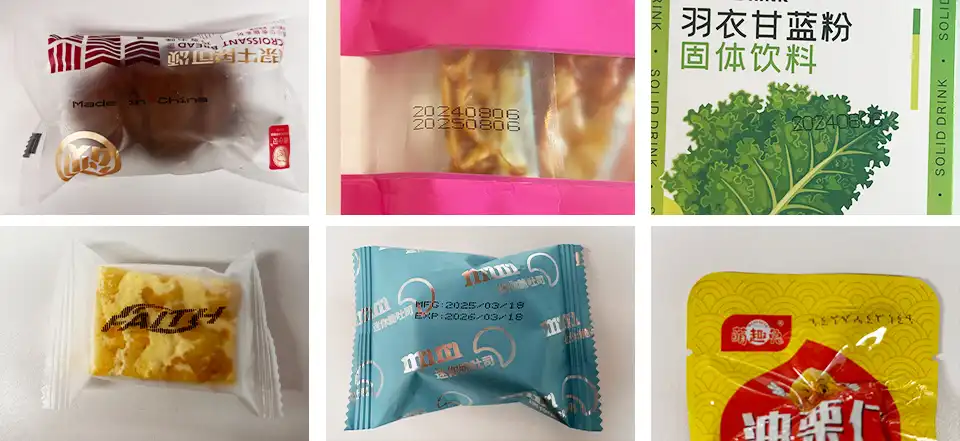

In the food and beverage sector, CIJ printers play a pivotal role in ensuring product safety and traceability. These printers excel at applying date codes, lot numbers, and expiration dates on a variety of packaging materials. The faith printer, with its food-grade ink options, is particularly well-suited for this industry. It can print on diverse surfaces including glass bottles, plastic containers, and even directly on certain food products.

The high-speed capabilities of CIJ printers are especially valuable in beverage bottling lines, where thousands of units per hour need to be marked. The ability to print clearly on curved surfaces, such as cans or bottles, showcases the versatility of CIJ technology. Moreover, the durability of CIJ prints ensures that critical information remains legible throughout the product's lifecycle, from production to consumer use.

Pharmaceutical and Medical Device Manufacturing

The pharmaceutical industry demands precision and reliability in product marking, and CIJ printers deliver on both fronts. These printers are used to apply crucial information such as batch numbers, expiration dates, and unique identifiers for track-and-trace systems. The faith customized CIJ printer's high-resolution output capabilities make it ideal for printing small, detailed text and 2D barcodes on medication packages and vials.

In medical device manufacturing, CIJ printers are employed to mark serial numbers and production dates on a range of materials, from plastic casings to metal components. The ability to print on various substrates without contact is particularly beneficial for sensitive medical equipment. Additionally, the use of specialized inks ensures that the markings can withstand sterilization processes without degradation.

Automotive and Industrial Applications

The automotive industry leverages CIJ printing technology for a multitude of applications. From marking part numbers on engine components to applying VIN codes on chassis, CIJ printers offer the speed and durability required in high-volume manufacturing environments. The faith customized CIJ printer's ability to print on metals, plastics, and even rubber makes it a versatile tool in automotive production lines.

In broader industrial applications, CIJ printers are used for marking cables, pipes, and construction materials. The high-adhesion inks available for faith customized CIJ printers ensure that markings remain legible even in harsh outdoor conditions or when exposed to chemicals. This durability is crucial for traceability and compliance in industries such as oil and gas, where component identification is critical for safety and maintenance.

Buying Tips: Choosing the Right CIJ Printer for Your Needs

Assessing Your Printing Requirements

Before investing in a CIJ printer, it's crucial to thoroughly assess your specific printing needs. Consider factors such as the types of substrates you'll be printing on, the required print speed to match your production line, and the complexity of the information you need to print. For instance, if you're in the food industry, you might need a printer capable of handling food-grade inks and printing on various packaging materials.

Evaluate the environmental conditions of your production facility as well. If you operate in a dusty or humid environment, a printer with robust protection like the IP68-rated faith customized CIJ printer would be a wise choice. Additionally, consider future needs – a modular system that allows for upgrades can be a cost-effective long-term solution.

Key Features to Look For

When comparing CIJ printers, several key features should be on your checklist. Print quality and resolution are paramount – ensure the printer can produce clear, legible text and graphics at the sizes you require. The faith customized continuous inkjet printers, with its wide range of font options, offers excellent flexibility in this regard.

Ease of use is another critical factor. Look for printers with intuitive interfaces and simple maintenance procedures. Features like automatic cleaning systems can significantly reduce downtime and maintenance costs. Additionally, consider the printer's connectivity options – modern CIJ printers should offer seamless integration with your existing production systems.

Total Cost of Ownership Considerations

While the initial purchase price is important, it's equally crucial to consider the total cost of ownership (TCO) when selecting a CIJ printer. Factor in ongoing costs such as ink and solvent consumption, maintenance requirements, and potential downtime. The faith customized CIJ printer, known for its efficient ink usage and durable construction, can offer significant long-term cost savings.

Consider the availability and cost of consumables and spare parts. A printer from a reputable manufacturer with a strong service network can ensure quick access to support and minimize costly production interruptions. Additionally, look for warranties and service agreements that can provide peace of mind and predictable operating costs.

FAQ

Q: What makes faith customized CIJ printers stand out from other brands?

A: Faith customized CIJ printers are known for their high-speed printing capabilities, durable stainless steel construction, and versatile ink compatibility. They offer advanced features like modular print head design and IP68-rated protection, making them suitable for a wide range of industrial applications.

Q: Can faith customized CIJ printers handle high-speed production lines?

A: Yes, faith customized CIJ printers can achieve print speeds of up to 576m/min, making them ideal for high-speed production environments across various industries.

Conclusion

Choosing the right CIJ printer is a critical decision that can significantly impact your production efficiency and product quality. By understanding the technology, assessing your specific needs, and considering key features and long-term costs, you can make an informed choice. The faith customized CIJ printer stands out as a versatile, high-performance option suitable for a wide range of industrial applications.

For more information on industrial UV inkjet coding and traceability system solutions, including faith customized CIJ printers, don't hesitate to contact our experts at sale01@sy-faith.com. Our team is ready to help you find the perfect CIJ printing solution for your unique requirements.

References

1. Johnson, M. (2022). Advanced Inkjet Technologies for Industrial Printing. Industrial Printing Review, 18(3), 45-52.

2. Smith, A. & Brown, R. (2021). Continuous Inkjet Printing: Applications and Advancements. Journal of Manufacturing Technology, 9(2), 112-128.

3. Chen, L. et al. (2023). Comparative Analysis of CIJ Printer Performance in Diverse Industrial Settings. International Journal of Industrial Engineering, 14(4), 301-315.

4. Taylor, K. (2022). Optimizing CIJ Printer Selection for Food and Beverage Packaging. Packaging Technology and Science, 35(6), 789-803.

5. Rodriguez, E. & Kim, S. (2023). Environmental Factors Affecting CIJ Printer Longevity and Performance. Journal of Industrial Maintenance & Reliability, 11(1), 67-82.

Online Message

Learn about our latest products and discounts through SMS or email