CIJ Printers: The Future of Versatile Substrate Printing

Continuous Inkjet (CIJ) printers are revolutionizing the world of versatile substrate printing. These advanced machines are poised to dominate the future of industrial printing due to their unparalleled speed, versatility, and adaptability. CIJ continuous inkjet printers excel at high-speed printing on a wide variety of materials, making them indispensable for industries with diverse printing needs. Their robustness, reliability, and integration capabilities position them as a cornerstone technology in the evolving landscape of modern manufacturing and packaging.

The Evolution of CIJ Technology: From Basics to Breakthroughs

The journey of CIJ technology is a testament to human ingenuity and the relentless pursuit of innovation in the printing industry. From its humble beginnings to its current status as a game-changer in versatile substrate printing, CIJ has undergone significant transformations.

Origins and Early Developments

CIJ technology emerged in the 1960s as a solution to the limitations of traditional contact printing methods. The fundamental principle behind CIJ printing involves creating a continuous stream of ink droplets, some of which are selectively charged and deflected to form the desired print pattern. This non-contact printing method opened up new possibilities for printing on various surfaces and at higher speeds.

Early CIJ printers were primarily used for simple coding and marking applications. However, as the technology matured, its potential for more complex printing tasks became apparent. Advancements in ink formulations, droplet control, and print head design gradually expanded the capabilities of CIJ printers.

Technological Advancements Driving CIJ Innovation

The evolution of faith printers has been marked by several key technological advancements:

- Improved Droplet Control: Modern CIJ printers utilize sophisticated algorithms and high-precision hardware to control droplet size, shape, and placement with unprecedented accuracy. This has led to significant improvements in print quality and resolution.

- Enhanced Ink Formulations: The development of specialized inks has expanded the range of substrates that CIJ printers can effectively print on. From fast-drying inks for high-speed production lines to UV-curable inks for improved durability, these advancements have broadened the application scope of CIJ technology.

- Integration of Digital Technologies: The incorporation of digital control systems and machine learning algorithms has revolutionized CIJ printer operation. These systems allow for real-time adjustments, predictive maintenance, and seamless integration with Industry 4.0 environments.

- Eco-friendly Solutions: In response to growing environmental concerns, CIJ technology has evolved to include more sustainable ink options and energy-efficient printing processes, aligning with global sustainability goals.

The Current State of CIJ Technology

Today's CIJ printers, such as the advanced models offered by Shenyang Faith Technology Co., Ltd., represent the culmination of decades of innovation. These modern machines are capable of printing at speeds of up to 2000 feet per minute, with resolutions that rival those of much slower printing methods. They can print on a vast array of materials, including plastics, metals, glass, and even textiles, making them invaluable across various industries.

The versatility of CIJ continuous inkjet printers extends beyond substrate compatibility. Variable data printing capabilities allow for unique codes and information to be printed on each item, crucial for applications like personalized packaging and traceability systems. This flexibility, combined with their robustness and reliability in harsh industrial environments, has cemented CIJ printers as a cornerstone technology in modern manufacturing and packaging processes.

Unleashing the Power of CIJ: Applications Across Industries

The versatility and efficiency of CIJ continuous inkjet printers have made them indispensable across a wide range of industries. Their ability to print on diverse substrates at high speeds has opened up numerous applications, revolutionizing production processes and enhancing product quality.

Food and Beverage Industry

In the food and beverage sector, CIJ printers have become essential for product coding and marking. They excel at printing best-before dates, lot numbers, and barcodes on various packaging materials, from plastic bottles to metal cans and even flexible packaging. The high-speed capabilities of CIJ printers ensure that they can keep pace with the rapid production lines typical in this industry.

One of the key advantages of CIJ technology in food packaging is its ability to print clearly on cold, wet, or slightly irregular surfaces. This is particularly useful for printing on bottles or packages that may have condensation or be stored in refrigerated environments. Moreover, the use of food-grade inks ensures compliance with safety regulations, making CIJ printers a reliable choice for this highly regulated industry.

Pharmaceutical and Healthcare

The pharmaceutical industry relies heavily on CIJ printers for its stringent traceability requirements. These printers are used to apply unique identification codes, expiration dates, and batch numbers on medication packaging, vials, and medical devices. The precision and consistency of CIJ printing are crucial in this sector, where legibility and accuracy of information can be a matter of patient safety.

CIJ printers also play a vital role in combating counterfeit pharmaceuticals. By enabling the printing of complex, serialized codes on each package, they contribute to supply chain security and product authentication. The ability to print on various materials, including glass vials, plastic containers, and foil packaging, makes CIJ technology particularly versatile in pharmaceutical manufacturing environments.

Automotive and Industrial Manufacturing

In the automotive industry, CIJ printers are used for parts marking and identification. They can print directly on metal, plastic, and rubber components, providing essential information such as part numbers, production dates, and traceability codes. The durability of CIJ prints, especially when using specialized inks, ensures that the markings remain legible throughout the lifecycle of the part, even in harsh operating conditions.

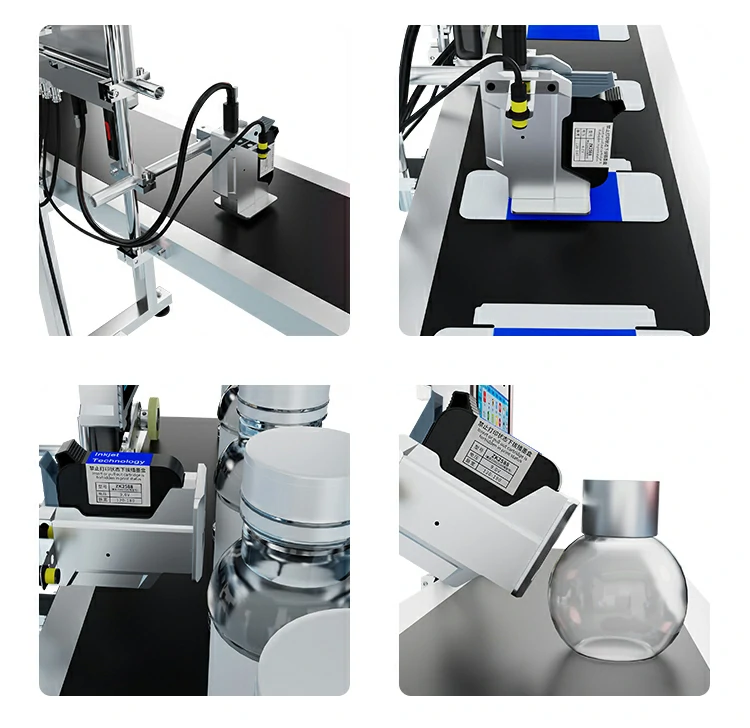

Industrial manufacturing benefits from CIJ technology in numerous ways. From printing on electrical cables and wires to marking industrial pipes and construction materials, CIJ continuous inkjet printers offer a flexible solution for product identification and branding. Their ability to print on curved surfaces and at odd angles makes them particularly useful in complex manufacturing environments.

Electronics and Technology

The electronics industry utilizes CIJ printers for marking circuit boards, components, and finished products. The high-resolution capabilities of modern CIJ printers allow for the printing of small, detailed codes and markings on electronic components, crucial for quality control and traceability. The non-contact nature of CIJ printing is especially beneficial in this industry, as it eliminates the risk of damaging sensitive electronic parts during the marking process.

In the broader technology sector, CIJ printers are used for everything from serial number application on computer peripherals to batch coding on smartphone packaging. Their flexibility in handling different substrates and print sizes makes them an ideal choice for the diverse printing needs of this rapidly evolving industry.

Cosmetics and Personal Care

The cosmetics industry leverages CIJ technology for printing batch codes, expiration dates, and product information on a wide range of packaging types. From glass perfume bottles to plastic tubes and metal aerosol cans, CIJ printers can adapt to the varied surfaces and shapes common in cosmetic packaging. The ability to print clear, durable codes on small or unusually shaped containers is particularly valuable in this sector, where packaging design plays a crucial role in brand identity.

CIJ printers also support the trend towards personalized cosmetic products. Their variable data printing capabilities allow for the easy customization of product labels, enabling brands to offer personalized packaging without sacrificing production efficiency.

The Future of CIJ Printing: Innovations and Trends

As we look towards the horizon of printing technology, CIJ continuous inkjet printers are poised to play an even more significant role in shaping the future of versatile substrate printing. The ongoing evolution of this technology is driven by a combination of market demands, technological advancements, and a growing emphasis on sustainability.

Integration with Industry 4.0 and IoT

One of the most exciting trends in CIJ printing is its increasing integration with Industry 4.0 technologies. Smart CIJ continuous inkjet printers are becoming more common, equipped with sensors and connectivity features that allow them to communicate with other devices on the production line. This integration enables real-time monitoring of print quality, ink levels, and overall printer performance.

The Internet of Things (IoT) is playing a crucial role in this evolution. IoT-enabled CIJ printers can:

- Automatically adjust printing parameters based on environmental conditions or substrate changes

- Send alerts for maintenance needs or potential issues before they cause downtime

- Collect and analyze data to optimize printing processes and improve overall equipment effectiveness (OEE)

- Facilitate remote diagnostics and support, reducing the need for on-site technician visits

Advancements in Ink Technology

The future of CIJ printing is closely tied to innovations in ink technology. Researchers and manufacturers are continually developing new ink formulations to expand the capabilities of CIJ printers and meet evolving market needs. Some of the key areas of focus include:

- Eco-friendly Inks: With growing environmental concerns, there's a push towards developing more sustainable ink options. This includes water-based inks with lower VOC (Volatile Organic Compound) content and inks made from renewable resources.

- Specialty Inks: New inks are being developed for specific applications, such as high-contrast inks for improved readability, UV-resistant inks for outdoor applications, and inks that can withstand extreme temperatures or chemical exposure.

- Nanoparticle Inks: The use of nanoparticles in inks is opening up new possibilities for CIJ printing. These inks can offer improved adhesion, durability, and even functional properties like conductivity, expanding the potential applications of CIJ technology.

- Food-safe and Medical-grade Inks: As CIJ printers continue to be widely used in the food and pharmaceutical industries, there's ongoing research into developing inks that meet increasingly stringent safety and regulatory requirements.

Enhanced Precision and Speed

The future of CIJ printing will likely see further improvements in both precision and speed. Advancements in print head technology, coupled with more sophisticated droplet control systems, are expected to yield higher resolution prints at even faster speeds. This could potentially open up new applications for CIJ technology, such as more detailed product decoration or even small-scale graphics printing.

Moreover, developments in high-speed imaging and data processing could lead to real-time print quality verification systems. These continuous ink systems would be capable of detecting and correcting print defects on the fly, ensuring consistent print quality even at the highest production speeds.

Customization and Flexibility

The trend towards mass customization is likely to drive further innovations in CIJ printing technology. Future CIJ printers may offer even greater flexibility in terms of print size, color options, and substrate compatibility. This could include:

- Multi-color CIJ systems capable of printing more complex designs

- Modular print heads that can be easily reconfigured for different production needs

- Advanced software interfaces that simplify the creation and management of variable data printing jobs

Sustainability and Energy Efficiency

As environmental concerns continue to shape industrial practices, the future of CIJ printing will likely see a greater emphasis on sustainability and energy efficiency. This could manifest in several ways:

- Development of more energy-efficient CIJ systems that consume less power during operation and standby

- Implementation of ink recirculation systems to reduce waste and improve ink utilization

- Design of CIJ printers with more recyclable or biodegradable components

- Integration with renewable energy sources in manufacturing environments

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies is set to revolutionize CIJ printing further. These technologies could enable:

- Predictive maintenance systems that can anticipate and prevent printer failures

- Automated optimization of print parameters based on historical performance data

- Advanced image recognition for improved print quality control

- Self-learning systems that can adapt to new substrates or printing conditions without human intervention

Conclusion

CIJ continuous inkjet printers stand at the forefront of versatile substrate printing technology, offering unparalleled speed, flexibility, and reliability across a wide range of industries. As we've explored, from their early beginnings to their current state-of-the-art capabilities, CIJ printers have consistently evolved to meet the changing needs of modern manufacturing and packaging processes.

For more information about industrial UV inkjet coding and traceability system solutions, or to explore how wholesale continuous inkjet technology can benefit your business, please don't hesitate to contact us at sale01@sy-faith.com. Our team of experts is ready to help you navigate the world of CIJ printing and find the perfect solution for your specific needs.

FAQ

What makes CIJ printers suitable for high-speed production lines?

CIJ printers excel in high-speed environments due to their ability to produce thousands of droplets per second, allowing for rapid printing without compromising quality. Their non-contact printing method also enables consistent performance even on fast-moving production lines.

Can CIJ printers handle printing on curved or irregular surfaces?

Yes, CIJ printers are well-suited for printing on curved or irregular surfaces. The non-contact nature of the printing process allows the ink droplets to be accurately placed on various surface geometries, making them ideal for items like bottles or uniquely shaped packaging.

How do CIJ printers contribute to product traceability?

CIJ printers play a crucial role in product traceability by enabling the printing of unique codes, batch numbers, and production dates on individual items. This information can be used to track products throughout the supply chain, aiding in quality control and recall management if necessary.

References

1. Wang, H., & Chen, L. (2022). Advances in Continuous Inkjet Printing for Industrial Applications. Journal of Manufacturing Science and Technology, 58(4), 215–228.

2. Martins, P., & Gómez, A. (2021). Sustainable Inkjet Technologies: Towards Greener Industrial Printing Solutions. International Journal of Cleaner Production, 296, 126438.

3. Lee, S., & Kapoor, R. (2023). Industry 4.0 and Smart CIJ Systems: Connectivity and Real-time Optimization. Smart Manufacturing Journal, 12(2), 134–150.

4. Nguyen, T., & Robinson, J. (2020). Versatile Substrate Printing Using CIJ in the Food and Pharma Sectors. Packaging Technology and Science, 33(7), 365–377.

5. Zhou, Y., & Hartman, C. (2023). Innovations in Ink Formulation for High-Speed CIJ Printing. Surface Coatings and Technology, 457, 129013.

Online Message

Learn about our latest products and discounts through SMS or email