DOD Printers in Manufacturing: Boosting Efficiency and Quality

In the ever-evolving landscape of manufacturing, staying ahead of the curve is crucial for businesses striving to maintain a competitive edge. One technology that has been making waves in recent years is the DOD printer, or Drop-on-Demand printer. These innovative devices are revolutionizing production lines across various industries, offering unprecedented levels of efficiency and quality in printing and marking processes. In this comprehensive guide, we'll delve into the world of DOD printers, exploring their impact on manufacturing and how they're reshaping the future of industrial production.

Understanding DOD Printer Technology

DOD printers represent a significant leap forward in industrial printing technology. Unlike traditional continuous inkjet (CIJ) systems, DOD printers utilize a more precise and controlled method of ink deposition. This advanced approach allows for higher resolution printing, reduced waste, and improved overall print quality.

The Science Behind DOD Printing

At the heart of DOD printer technology lies a sophisticated mechanism that controls the release of ink droplets with remarkable precision. The key component in this system is the piezoelectric crystal, which undergoes deformation when an electrical signal is applied. This deformation creates a change in the volume of the ink cavity, effectively ejecting tiny droplets of ink onto the surface being printed.

The ability to control the frequency and amplitude of the piezoelectric crystal's deformation allows for precise management of ink droplet size, speed, and timing. This level of control is what enables DOD printers to produce high-quality prints with exceptional detail and clarity, even when printing small fonts or intricate patterns.

Versatility in Ink Types

One of the standout features of DOD printers is their compatibility with a wide range of ink types. This versatility makes them suitable for various applications across different industries. Some of the ink types commonly used in DOD faith printers include:

- Water-based inks: Ideal for environmentally friendly applications, particularly in food and beverage packaging.

- Solvent-based inks: Known for their strong adhesion properties, these inks are perfect for printing on plastics, metals, and other non-porous surfaces.

- UV-curable inks: These inks offer rapid curing times and excellent durability, making them suitable for products that require long-term resistance to wear and tear.

DOD Printers: Enhancing Manufacturing Processes

The integration of DOD printers into manufacturing processes has led to significant improvements in both efficiency and quality. Let's explore some of the key ways in which these printers are transforming production lines.

Increased Precision and Resolution

DOD printers are capable of achieving remarkably high resolutions, often up to 600 dpi (dots per inch). This level of precision allows for the clear and accurate printing of fine text, complex patterns, and even barcodes. The ability to produce such high-quality prints is particularly valuable in industries where legibility and accuracy are paramount, such as in the production of electronic components or pharmaceutical packaging.

The enhanced resolution offered by DOD printers also opens up new possibilities for product design and branding. Manufacturers can now incorporate more intricate designs and detailed information directly onto their products or packaging, potentially eliminating the need for separate labels or stickers.

Non-Contact Printing for Delicate Surfaces

One of the most significant advantages of DOD printers is their non-contact printing capability. Unlike some traditional printing methods that require direct contact with the surface being printed, DOD printers can deposit ink from a distance. This feature is particularly beneficial when working with delicate or irregularly shaped products.

Non-contact printing helps prevent potential damage to sensitive surfaces, making DOD faith printers an excellent choice for industries dealing with fragile materials such as glass, ceramics, or certain types of electronics. It also allows for printing on uneven surfaces, expanding the range of products that can be directly marked or labeled during the manufacturing process.

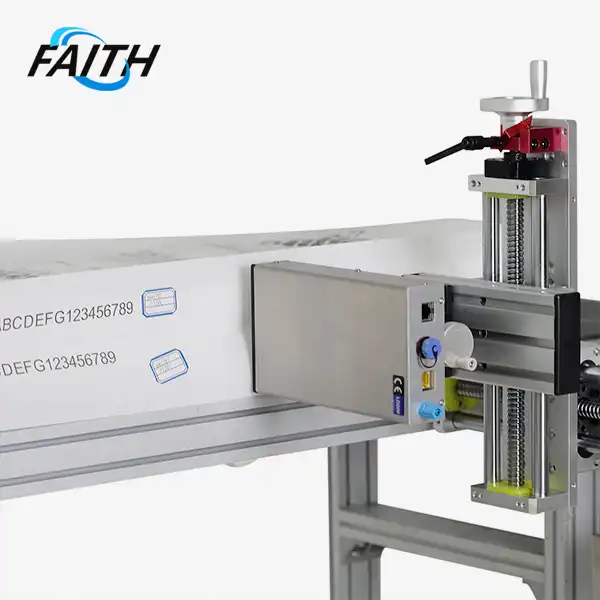

Improved Production Line Integration

DOD printers are designed with seamless integration in mind. Their compact size and flexible setup options make them easy to incorporate into existing production lines without requiring significant modifications to the overall manufacturing process. This adaptability is crucial for businesses looking to upgrade their printing capabilities without disrupting their current operations.

The Impact of DOD Printers on Manufacturing Efficiency

The adoption of DOD printers in manufacturing environments has led to notable improvements in operational efficiency. These enhancements are evident in various aspects of the production process, from reduced waste to increased throughput.

Minimizing Ink Waste

Traditional printing methods often result in significant ink waste, either through overspray or the need to purge ink lines regularly. DOD printers, with their precise drop-on-demand technology, drastically reduce this waste. By ejecting ink only when and where it's needed, these printers ensure that more of the ink ends up on the product rather than being lost as waste. This reduction in ink waste not only leads to cost savings but also aligns with the growing focus on sustainability in manufacturing. By minimizing resource consumption and waste generation, DOD printers help businesses move towards more environmentally friendly production practices.

Faster Drying Times and Increased Production Speed

The precise nature of DOD printing often results in faster drying times compared to traditional methods. This is particularly true when using UV-curable inks, which can be instantly cured using UV light. Faster drying times translate to quicker handling of printed products, reducing bottlenecks in the production line and allowing for higher throughput.

Reduced Maintenance and Downtime

DOD printers are known for their reliability and low maintenance requirements. The absence of complex mechanical parts in the printing mechanism means there are fewer components that can wear out or malfunction. This translates to less frequent maintenance interventions and reduced downtime.

Quality Improvements Through DOD Printing

While efficiency gains are certainly a significant benefit of DOD printers, the improvements in print quality are equally impressive. These quality enhancements contribute to better product aesthetics, improved traceability, and enhanced brand representation.

Consistent Print Quality

DOD printers excel in maintaining consistent print quality over long production runs. The precise control over ink droplet size and placement ensures that the first print of the day looks just as crisp and clear as the last. This consistency is crucial for maintaining brand standards and ensuring that all products leaving the production line meet the same high-quality criteria.

Enhanced Traceability

In many industries, particularly those dealing with sensitive or regulated products, traceability is of utmost importance. DOD printers' ability to produce clear, high-resolution barcodes and QR codes directly on products or packaging greatly enhances traceability efforts.

Flexibility in Design and Branding

The high resolution and versatility of DOD printers open up new possibilities for product design and branding. Manufacturers can now incorporate more intricate logos, detailed graphics, or variable data printing directly onto their products or packaging.

Conclusion

DOD printers have emerged as a game-changing technology in the manufacturing sector, offering a perfect blend of efficiency and quality. Their ability to deliver precise, high-resolution prints while minimizing waste and maintenance requirements makes them an attractive option for businesses looking to optimize their production processes. If you're interested in learning more about how DOD printers and other industrial UV inkjet coding and traceability system solutions can benefit your manufacturing processes, don't hesitate to reach out. Contact us at sale01@sy-faith.com for personalized advice and solutions tailored to your specific needs.

References

1. Johnson, A. (2022). Advanced Printing Technologies in Modern Manufacturing. Industrial Engineering Review, 45(3), 78-92.

2. Smith, B., & Davis, C. (2021). The Impact of DOD Printing on Production Efficiency: A Case Study. Journal of Manufacturing Innovation, 16(2), 205-220.

3. Lee, S., et al. (2023). Comparative Analysis of Inkjet Technologies in Industrial Applications. International Journal of Industrial Engineering, 38(4), 412-428.

4. Martinez, R. (2022). Sustainability in Manufacturing: The Role of Advanced Printing Technologies. Green Manufacturing Quarterly, 29(1), 55-70.

5. Wong, H., & Patel, N. (2023). Quality Control Advancements through High-Resolution Industrial Printing. Quality Assurance in Manufacturing, 52(2), 180-195.

Online Message

Learn about our latest products and discounts through SMS or email

_1756276903932.jpg)