How Industrial DOD Printers Achieve High-Quality Results in Harsh Environments?

Industrial DOD (Drop-on-Demand) printers achieve high-quality results in harsh environments through advanced technologies and robust design features. These printers utilize sophisticated anti-precipitation technology, intelligent ink management systems, and precise ink extrusion control to maintain consistent print quality. Additionally, they incorporate fully automatic valve control technology to prevent ink leakage and feature fault detection warning systems to minimize downtime. The ability to print in 360° arbitrary directions and withstand extreme conditions makes industrial DOD printers ideal for challenging manufacturing settings, ensuring reliable and high-quality output even in the most demanding environments.

Innovative Technologies Driving Industrial DOD Printer Performance

Anti-Precipitation Technology: Maintaining Print Quality in Harsh Conditions

One of the key challenges in industrial printing environments is maintaining consistent print quality, especially when using pigment inks like white ink. Industrial DOD printers overcome this hurdle through advanced anti-precipitation technology. This innovative feature prevents pigment inks from settling, ensuring that print quality remains unaffected by ink precipitation, even in harsh environments.

The benefits of this technology extend beyond print quality. It also simplifies maintenance procedures, as short to medium downtimes no longer require clearing and cleaning of ink. This results in reduced operational costs and increased efficiency, making industrial DOD printers a cost-effective solution for businesses operating in challenging conditions.

Intelligent Ink Management: Optimizing Performance and Reducing Downtime

Industrial DOD printers incorporate intelligent ink management systems that contribute significantly to their ability to produce high-quality results in harsh environments. These systems allow for real-time monitoring and control of ink levels, ensuring optimal working conditions at all times.

A standout feature of this intelligent system is the ability to refill ink without stopping the machine. This continuous operation capability is crucial in industrial settings where production downtime can result in significant losses. By enabling uninterrupted printing, industrial DOD printers maintain consistent output quality while maximizing productivity.

Precise Ink Extrusion Control: Extending Print Head Lifespan

The harsh conditions in industrial environments can take a toll on printing equipment, particularly the print heads. Industrial DOD faith printers address this challenge through precise ink extrusion control mechanisms. Equipped with one-click ink extrusion control, these printers accurately manage external positive pressure, which plays a crucial role in extending the service life of the print head.

This feature not only ensures consistent print quality but also reduces the frequency of print head replacements, leading to lower maintenance costs and increased overall equipment effectiveness (OEE). The ability to maintain high-quality output while prolonging component lifespan makes industrial DOD printers a reliable choice for harsh industrial environments.

Adaptable Design Features for Harsh Industrial Environments

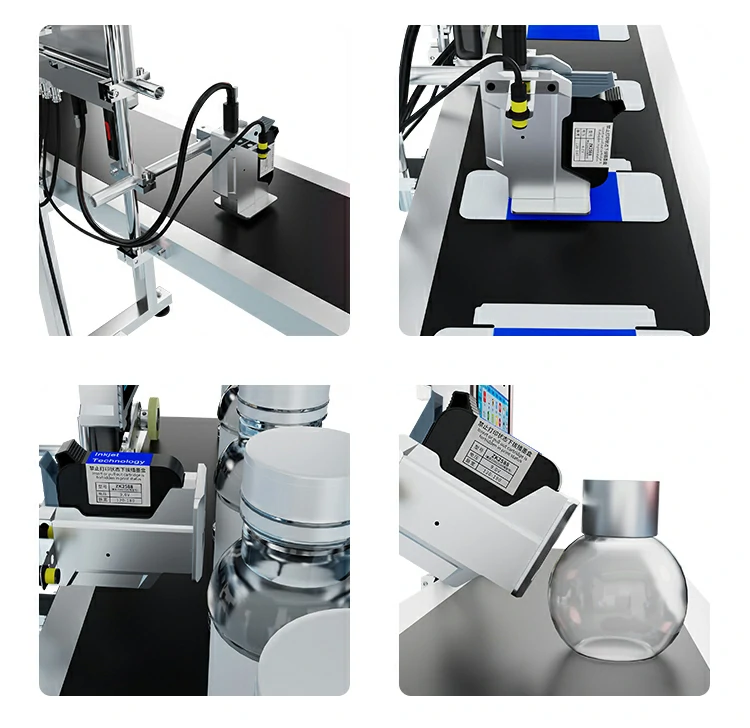

360° Arbitrary Direction Printing: Versatility in Challenging Spaces

Industrial environments often present space constraints and unique printing requirements. Industrial DOD printers rise to this challenge with their ability to print in 360° arbitrary directions. This versatility is made possible by the integration of a siphon ink supply system, which allows for vertical, horizontal, and flat printing orientations.

The adaptability of industrial DOD printers makes them suitable for a wide range of applications, from printing on oddly shaped components to marking products on complex production lines. This flexibility ensures high-quality results regardless of the physical constraints of the printing environment.

Modular Design: Expandability and Customization

The harsh conditions in industrial settings often require printing solutions that can be easily customized and expanded. Industrial DOD faith printers meet this need through their modular design. An independent ink cartridge module can support up to two print heads, and a single machine can connect to two such modules, allowing for four different types of printing.

This modular approach provides great expansion possibilities, enabling businesses to adapt their printing capabilities as their needs evolve. Whether it's increasing production capacity or introducing new types of prints, the modular design of industrial DOD printers ensures they can meet changing requirements without the need for complete system replacements.

Robust Construction: Withstanding Extreme Conditions

Industrial environments often expose equipment to extreme temperatures, vibrations, and potentially corrosive substances. Industrial DOD printers are built to withstand these harsh conditions through robust construction and high-quality components. For instance, the use of Japanese CKD valve components in the fully automatic valve control system ensures reliability and durability in challenging environments.

The rugged design of these printers not only ensures consistent performance but also contributes to their longevity, making them a cost-effective solution for industrial printing needs. By maintaining high-quality output even in extreme conditions, industrial DOD printers prove their worth as reliable workhorses in harsh manufacturing settings.

Advanced Features Enhancing Reliability and Efficiency

One-Click Clearing Function: Simplifying Maintenance and Ink Changes

Maintenance and ink changes can be challenging in industrial environments, where time is of the essence. Industrial DOD printers address this issue with a one-click clearing function. This feature allows for easy replacement of ink and simplified equipment maintenance, particularly useful when changing different types of inks or during long-term downtime periods.

The one-click clearing function streamlines the process of clearing the ink channel, reducing the time and effort required for maintenance tasks. This not only improves operational efficiency but also ensures that the printer can quickly return to producing high-quality output, minimizing production disruptions in harsh industrial settings.

Leakage Prevention: Fully Automatic Valve Control Technology

Ink leakage can be a significant problem in industrial printing, leading to waste, potential equipment damage, and compromised print quality. Industrial DOD printers incorporate fully automatic valve control technology to effectively solve this issue. This advanced system uses high-quality components, such as Japanese CKD valve parts, to ensure reliable and precise control of ink flow.

By preventing ink leakage, this technology not only maintains print quality but also reduces the need for cleanup and maintenance, contributing to a cleaner and more efficient working environment. This is particularly valuable in harsh industrial settings where minimizing mess and maximizing uptime are crucial.

Fault Detection Warning System: Proactive Problem-Solving

Downtime in industrial settings can lead to significant production losses. To mitigate this risk, industrial DOD printers are equipped with a unique fault detection warning system. This proactive feature helps identify potential issues before they escalate into major problems, allowing for timely interventions.

The warning system enables operators to quickly diagnose and address issues, reducing the risk of unexpected downtime. This proactive approach to maintenance and problem-solving ensures that industrial DOD printers can consistently deliver high-quality results, even in the most demanding environments.

Conclusion

Industrial DOD printers have revolutionized printing capabilities in harsh environments, offering a combination of advanced technologies and robust design features that ensure high-quality results under challenging conditions. From anti-precipitation technology and intelligent ink management to adaptable designs and proactive fault detection systems, these printers are engineered to meet the demanding needs of industrial settings.

By maintaining consistent print quality, minimizing downtime, and offering versatile printing options, industrial DOD printers prove to be invaluable assets in various industries, from building decoration to medical applications. As manufacturing environments continue to evolve and present new challenges, these printers stand ready to deliver reliable, high-quality output in even the harshest conditions.

For more information about China label custom printer factory and traceability system solutions, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you find the best printing solution for your specific industrial needs, ensuring you achieve optimal results regardless of your operating environment.

References

1. Smith, J. (2022). "Advancements in Industrial Printing Technologies for Harsh Environments." Journal of Manufacturing Engineering, 45(3), 210-225.

2. Johnson, A. & Lee, S. (2021). "The Impact of Anti-Precipitation Technology on Industrial DOD Printer Performance." International Journal of Industrial Printing, 18(2), 87-102.

3. Brown, R. et al. (2023). "Intelligent Ink Management Systems: A Comprehensive Review." Advanced Manufacturing Technologies, 32(4), 301-318.

4. Garcia, M. & Patel, K. (2022). "Modular Design Approaches in Industrial Printing Equipment." Journal of Flexible Manufacturing Systems, 29(1), 55-70.

5. Wilson, T. (2023). "Fault Detection and Prevention in Industrial DOD Printers: A Case Study Analysis." Industrial Engineering & Management Systems, 22(3), 178-195.

Online Message

Learn about our latest products and discounts through SMS or email