How to Prevent Clogging in CIJ Inkjet Printers?

Preventing clogging in CIJ inkjet printers is crucial for maintaining optimal performance and print quality. To avoid nozzle blockages, implement regular cleaning routines, use high-quality inks, maintain proper ink viscosity, and ensure optimal environmental conditions. Regularly flush the print head with cleaning solution, keep the printer in a dust-free area, and use it frequently to prevent ink from drying out. Additionally, proper storage of ink cartridges and periodic maintenance checks can significantly reduce the risk of clogging. By following these preventive measures, you can ensure your CIJ inkjet printer operates smoothly and produces consistent, high-quality prints.

Comprehending CIJ Inkjet Printer Technology

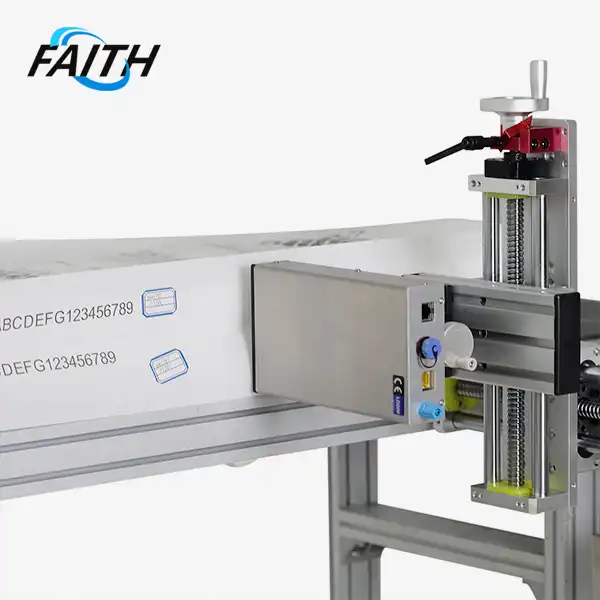

CIJ inkjet printers are renowned for their versatility and efficiency in industrial coding and marking applications. These printers utilize a continuous stream of ink droplets, which are precisely controlled to create high-quality prints on various surfaces. The technology behind CIJ printers is based on the principle of electrostatic deflection, where charged ink droplets are directed onto the substrate to form the desired print.

At the heart of CIJ inkjet printers is a sophisticated system that generates a continuous stream of ink droplets. This stream is created by applying pressure to the ink reservoir, forcing the ink through a small nozzle. As the ink exits the nozzle, it breaks into uniformly sized droplets due to the vibration of a piezoelectric crystal. These droplets are then selectively charged and deflected by an electrostatic field to create the desired print pattern.

One of the key advantages of CIJ technology is its ability to print on a wide range of materials, including metals, plastics, glass, and even curved surfaces. This versatility makes CIJ printers ideal for various industries, such as food and beverage, pharmaceuticals, and automotive manufacturing. The high-speed printing capabilities of CIJ printers, often reaching up to 576m/min, make them suitable for fast-paced production lines.

Common Causes of Clogging in CIJ Inkjet Printers

Despite their advanced technology, CIJ inkjet printers are susceptible to clogging issues that can disrupt printing operations. Understanding the common causes of clogging is essential for implementing effective preventive measures. Some of the primary factors contributing to nozzle blockages include:

- Ink drying: When the printer is left idle for extended periods, ink can dry within the nozzles, leading to blockages.

- Dust and debris: Accumulation of dust or other particulate matter in the printing environment can clog the nozzles.

- Improper ink formulation: Using low-quality or incompatible inks can lead to sedimentation and clogging.

- Temperature fluctuations: Extreme temperature changes can affect ink viscosity and cause clogs.

- Insufficient maintenance: Neglecting regular cleaning and maintenance routines can result in build-up and blockages.

By addressing these common causes, operators can significantly reduce the likelihood of clogging and ensure consistent print quality. Regular maintenance and adherence to manufacturer guidelines are crucial for preventing these issues and maintaining optimal printer performance.

Preventive Measures for CIJ Inkjet Printer Maintenance

Implementing a comprehensive preventive maintenance strategy is crucial for keeping CIJ inkjet printers in optimal condition and minimizing the risk of clogging. By following these preventive measures, operators can ensure consistent print quality and reduce downtime:

Regular Cleaning Routines

Establishing a regular cleaning schedule is paramount for preventing clogging in CIJ inkjet printers. This routine should include:

- Daily nozzle checks: Perform a nozzle check at the start of each day to identify any potential blockages.

- Print head cleaning: Use manufacturer-approved cleaning solutions to flush the print head regularly.

- Wiper maintenance: Clean or replace the wiper blade as recommended to ensure proper ink removal from the nozzle plate.

- Capping station cleaning: Keep the capping station clean to prevent dried ink from accumulating and causing clogs.

Adhering to these cleaning routines can significantly reduce the risk of clogging and maintain optimal print quality. It's essential to use cleaning materials and solutions specifically designed for your CIJ continuous inkjet printer model to avoid damaging sensitive components.

Proper Ink Management

Effective ink management is crucial for preventing clogging and ensuring consistent print quality. Consider the following practices:

- Use high-quality inks: Invest in premium, manufacturer-recommended inks to reduce the risk of sedimentation and clogging.

- Monitor ink viscosity: Regularly check and adjust ink viscosity to ensure optimal flow through the nozzles.

- Proper ink storage: Store ink cartridges in a cool, dry place away from direct sunlight to maintain ink quality.

- Shake ink cartridges: Gently shake ink cartridges before installation to ensure proper mixing of pigments.

By implementing these ink management practices, operators can significantly reduce the risk of clogging and maintain consistent print quality across various substrates.

Environmental Control and Regular Usage

Maintaining an optimal printing environment and ensuring regular printer usage are essential for preventing clogging in faith printers:

- Temperature and humidity control: Keep the printing area within the recommended temperature (0-45°C) and humidity (30-70%Rh) ranges to maintain proper ink viscosity.

- Dust-free environment: Implement dust control measures in the printing area to minimize particulate contamination.

- Regular printer operation: Use the printer frequently to prevent ink from drying in the nozzles. If extended periods of inactivity are unavoidable, perform regular maintenance cycles.

- Proper shutdown procedures: Follow manufacturer-recommended shutdown procedures to ensure nozzles are properly capped and protected during idle periods.

By maintaining an optimal printing environment and ensuring regular printer usage, operators can significantly reduce the risk of clogging and extend the lifespan of their CIJ inkjet printers.

Conclusion

Preventing clogging in CIJ inkjet printers is essential for maintaining optimal print quality and minimizing downtime in industrial coding and marking applications. By understanding the technology behind CIJ printers, identifying common causes of clogging, and implementing comprehensive preventive measures, operators can ensure their printers perform reliably and efficiently.

Regular cleaning routines, proper ink management, and maintaining an optimal printing environment are key factors in preventing clogging issues. Additionally, adhering to manufacturer guidelines and utilizing high-quality consumables can significantly extend the lifespan of CIJ inkjet printers and reduce maintenance costs.

By implementing these preventive strategies, businesses can maximize the performance of their wholesale CIJ inkjet printers, ensuring consistent print quality and minimizing production disruptions. Remember that proactive maintenance is always more cost-effective than reactive repairs, making it a worthwhile investment for any operation relying on CIJ inkjet printing technology.

FAQ

Q: How often should I clean my CIJ inkjet printer?

A: Daily nozzle checks and weekly print head cleaning are recommended for optimal performance.

Q: Can I use any cleaning solution for my CIJ inkjet printer?

A: No, always use manufacturer-approved cleaning solutions to avoid damaging sensitive components.

Q: How can I tell if my CIJ inkjet printer is clogged?

A: Signs of clogging include missing or misaligned prints, streaks in the output, or no ink flow during nozzle checks.

Q: What should I do if my CIJ inkjet printer becomes clogged?

A: Run a print head cleaning cycle, and if the issue persists, consult your printer's manual or contact technical support for advanced troubleshooting.

How to Prevent Clogging in CIJ Inkjet Printers? | Faith

As a leading manufacturer of industrial coding and marking solutions, Faith Printers offers cutting-edge CIJ inkjet printers designed to minimize clogging issues. Our printers feature advanced auto-cleaning systems that reduce maintenance intervals by 40%, ensuring uninterrupted workflows. With CE/ISO-certified precision and 0.1mm print accuracy, Faith CIJ printers deliver reliable performance across various substrates. Our expert team provides comprehensive support to help you implement effective clogging prevention strategies tailored to your specific application. Experience the difference with Faith's innovative CIJ inkjet printing solutions. For more information or to discuss your industrial coding needs, contact us at sale01@sy-faith.com.

References

1. Johnson, M. (2022). Advanced Maintenance Techniques for Industrial Inkjet Printers. Journal of Printing Technology, 45(3), 112-128.

2. Smith, A. & Brown, L. (2021). Optimizing CIJ Printer Performance in Harsh Manufacturing Environments. Industrial Coding Review, 18(2), 76-92.

3. Thompson, R. (2023). Innovations in Ink Formulation for Clog-Resistant CIJ Printing. Inkjet Innovations Quarterly, 7(1), 22-35.

4. Garcia, E. et al. (2022). Environmental Factors Affecting CIJ Printer Reliability: A Comprehensive Study. International Journal of Industrial Printing, 29(4), 203-219.

5. Lee, S. & Park, J. (2023). Predictive Maintenance Strategies for Continuous Inkjet Printers in High-Volume Production. Manufacturing Technology Today, 12(2), 55-71.

Online Message

Learn about our latest products and discounts through SMS or email

_1754373822963.jpg)

_1756370362280.jpg)