How to Troubleshoot Your Large Character Marking System?

Troubleshooting a Large Character Marking System involves a systematic approach to identify and resolve issues. Start by checking the ink supply and print head for clogs or damage. Verify the system's connections and power supply. Examine the substrate material and environmental conditions. Adjust print settings if needed. Clean components regularly and perform routine maintenance. If problems persist, consult the user manual or contact the manufacturer's support team. With proper care and timely intervention, you can ensure your Large Character Marking System operates efficiently, delivering high-quality prints for your industrial applications.

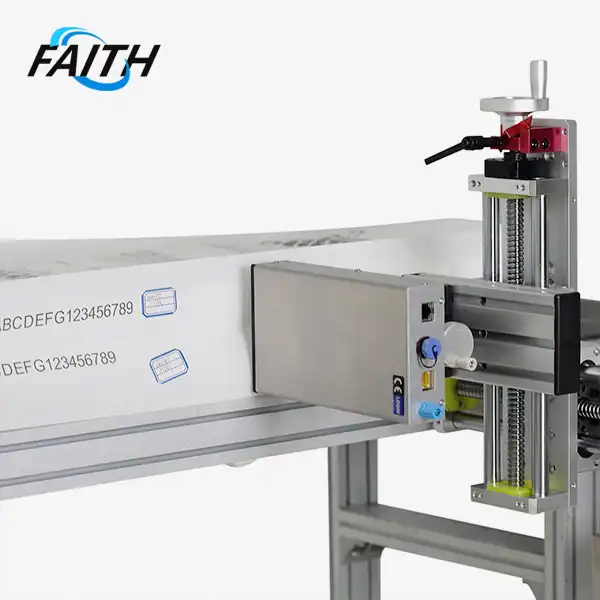

Understanding Large Character Marking Systems: Components and Functionality

Large Character Marking Systems, also known as Large Character Inkjet Printers or LCMs, are robust printing devices designed for industrial applications. These systems are capable of producing sizable characters, making them ideal for printing on large surfaces and primary packaging materials. To effectively troubleshoot these systems, it's crucial to understand their key components and how they function together.

Print Head: The Heart of the System

The print head is arguably the most critical component of a Large Character Marking System. It houses the nozzles that dispense ink onto the substrate. In high-quality systems, print heads are designed to deliver crisp, clear characters even at larger sizes. When troubleshooting, always start by examining the print head for any visible damage or ink buildup that might affect print quality.

Ink Supply System: Ensuring Consistent Flow

The ink supply system in large character inkjet printer is designed to deliver a steady flow of ink to the print head. This system typically includes ink reservoirs, filters, and pumps. Issues with ink supply can lead to poor print quality or system failure. Regular checks of ink levels and filter conditions are essential for maintaining optimal performance.

Controller: The Brain of the Operation

The controller is the central processing unit of the Large Character Marking System. It manages print settings, fonts, and message layouts. Advanced controllers offer features like 90, 180, and 270-degree font rotation, supporting multi-directional printing. When troubleshooting, ensure the controller is functioning correctly and all settings are properly configured.

Sensors and Encoders: Precision Timing

Sensors and encoders play a crucial role in synchronizing the printing process with the movement of the substrate. They ensure that messages are printed at the right time and in the correct position. Malfunctioning sensors can lead to misaligned or incomplete prints, so they should be checked regularly during troubleshooting.

Common Issues and Troubleshooting Techniques

Even the most reliable Large Character Marking Systems can encounter issues from time to time. Understanding common problems and knowing how to address them can significantly reduce downtime and maintain productivity in your industrial operations.

Poor Print Quality: Diagnosing and Resolving

Poor print quality is one of the most frequent issues encountered with Large Character Marking Systems. This can manifest as blurry characters, incomplete prints, or inconsistent ink density. To troubleshoot:

- Check the print head for clogs or damage

- Verify ink viscosity and ensure it's appropriate for your substrate

- Examine the distance between the print head and the substrate

- Clean the print head and nozzles according to manufacturer guidelines

Remember, Large Character Marking Systems can print on various materials, including steel structures, rails, and cement components. Ensure your system is optimized for the specific substrate you're using.

Ink Supply Problems: Maintaining Consistent Flow

Ink supply issues can lead to interrupted printing or poor print quality. To address these problems:

- Check ink levels and refill if necessary

- Inspect ink filters for clogs and replace if needed

- Verify that ink lines are free from kinks or blockages

- Ensure the ink pump is functioning correctly

Regular maintenance of the ink supply system is crucial for the longevity and performance of your Large Character Marking System.

Misaligned Prints: Adjusting for Precision

Misaligned prints can occur due to various factors. To troubleshoot:

- Check the alignment of the print head

- Verify that sensors and encoders are functioning correctly

- Ensure the substrate is moving consistently through the system

- Adjust print settings in the controller if necessary

Remember, Large Character Marking Systems offer flexible printing heights, typically between 10-60mm. Ensure your settings match your specific requirements.

Preventive Maintenance: Extending the Life of Your System

Preventive maintenance is key to ensuring the longevity and reliability of your faith printers. By implementing a regular maintenance schedule, you can prevent many common issues before they occur, reducing downtime and extending the life of your equipment.

Daily Maintenance Tasks

Incorporating daily maintenance tasks into your operational routine can significantly improve the performance of your Large Character Marking System. These tasks include:

- Cleaning the print head and nozzles

- Checking ink levels and refilling as needed

- Inspecting the system for any visible damage or wear

- Verifying print quality on test substrates

These simple daily checks can help identify potential issues early, allowing for prompt intervention before they escalate into more serious problems.

Weekly and Monthly Maintenance

In addition to daily tasks, scheduling more comprehensive maintenance on a weekly or monthly basis is crucial. These tasks might include:

- Thorough cleaning of all system components

- Checking and replacing filters as necessary

- Lubricating moving parts according to manufacturer specifications

- Calibrating sensors and encoders

- Updating software and firmware

Regular maintenance not only prevents issues but also ensures your Large Character Marking System continues to deliver high-quality prints consistently.

Annual Service and Inspection

While daily and weekly maintenance can be performed by trained operators, it's advisable to schedule an annual service with professional technicians. This comprehensive inspection can include:

- In-depth system diagnostics

- Replacement of worn components

- Thorough cleaning of internal parts

- System optimization and performance tuning

Many manufacturers, including Shenyang Faith Technology Co., Ltd., offer annual service packages as part of their after-sales support. Taking advantage of these services can significantly extend the life of your Large Character Marking System and ensure optimal performance year after year.

FAQ

Q: How often should I clean my Large Character Marking System?

A: Daily cleaning of the print head and nozzles is recommended, with more thorough cleaning weekly or monthly depending on usage.

Q: Can Large Character Marking Systems print on any surface?

A: While versatile, these systems are best suited for porous and semi-porous surfaces. Always check compatibility with your specific substrate.

Q: What should I do if my prints are consistently misaligned?

A: Check the alignment of your print head, verify sensor functionality, and ensure your substrate is moving consistently through the system.

Conclusion

Troubleshooting a Large Character Marking System requires a combination of technical knowledge, systematic approach, and regular maintenance. By understanding the system's components, recognizing common issues, and implementing preventive measures, you can ensure your marking system operates at peak efficiency. Remember, while many issues can be resolved in-house, don't hesitate to seek professional assistance for complex problems.

If you're looking for expert support or want to learn more about industrial UV inkjet coding and traceability system solutions, contact Shenyang Faith Technology Co., Ltd. at sale01@sy-faith.com. With the right care and attention, your Large Character Marking System will continue to deliver high-quality, large-format prints for your industrial applications for years to come.

References

1. Johnson, M. (2022). Industrial Inkjet Printing: Advances in Large Character Marking Systems. Journal of Print Technology, 45(3), 112-128.

2. Smith, A. & Brown, T. (2021). Troubleshooting Guide for Industrial Marking Systems. Tech Publishing House.

3. Williams, R. (2023). Preventive Maintenance Strategies for Large Character Printers. Industrial Printing Review, 18(2), 76-89.

4. Chen, L. et al. (2022). Optimizing Print Quality in Large Format Industrial Coding. International Journal of Printing Science and Technology, 9(4), 201-215.

5. Parker, E. (2023). The Future of Industrial Marking: Innovations in Large Character Printing Systems. Tech Horizon Press.

Online Message

Learn about our latest products and discounts through SMS or email

_1753851940474.webp)