Industrial CIJ Printing Systems: Precision Meets Versatility

Industrial Continuous Inkjet (CIJ) printing systems represent the pinnacle of precision and versatility in modern manufacturing. These non-contact printing solutions have revolutionized product coding, marking, and identification across diverse industries. By combining high-speed capabilities with the ability to print on a wide array of materials and surfaces, industrial CIJ printing systems have become indispensable tools for businesses seeking efficient, reliable, and adaptable printing solutions. From food packaging to automotive components, these systems deliver consistent, high-quality results in even the most demanding production environments.

The Evolution and Impact of Industrial CIJ Printing Technology

The journey of industrial CIJ printing systems from their inception to their current state-of-the-art status is a testament to technological innovation. Initially developed in the 1960s, CIJ technology has undergone significant refinements, resulting in today's sophisticated systems that offer unparalleled precision and flexibility.

Origins and Early Developments

The concept of continuous inkjet printing was first introduced by Lord Rayleigh in the late 19th century. However, it wasn't until the 1960s that the technology found practical applications in industrial settings. Early CIJ systems were primarily used for simple coding tasks, such as adding date codes to food packaging.

As the technology matured, manufacturers began to recognize its potential for more complex printing applications. The ability to print without contact with the substrate opened up new possibilities for marking irregularly shaped products and delicate materials.

Technological Advancements

Over the decades, CIJ printing systems have benefited from numerous technological advancements. These improvements have enhanced their performance, reliability, and versatility:

- Ink Formulations: The development of specialized inks has expanded the range of substrates that can be printed on, including plastics, metals, and glass.

- Printhead Technology: Innovations in printhead design have led to increased precision and reduced maintenance requirements.

- Digital Controls: The integration of digital control systems has improved print quality and allowed for more complex printing patterns.

- Software Integration: Modern CIJ systems can seamlessly integrate with production line management software, enhancing traceability and quality control.

Impact on Industrial Processes

The adoption of industrial CIJ printing systems has had a profound impact on manufacturing processes across various sectors:

- Increased Efficiency: High-speed printing capabilities allow for faster production lines without compromising print quality.

- Enhanced Traceability: Accurate and consistent coding enables better tracking of products throughout the supply chain.

- Reduced Waste: The non-contact nature of CIJ printing minimizes the risk of product damage during the marking process.

- Improved Compliance: CIJ systems help manufacturers meet regulatory requirements for product labeling and identification.

As industrial CIJ printing technology continues to evolve, it promises to play an even more crucial role in shaping the future of manufacturing and product identification.

Core Components and Functionality of CIJ Printing Systems

Understanding the inner workings of industrial CIJ printing systems is crucial for appreciating their capabilities and optimizing their performance. These systems comprise several key components that work in harmony to deliver precise and consistent printing results.

Essential Components

A typical industrial CIJ printer consists of the following core elements:

- Ink Reservoir: This component stores the ink and maintains it at the optimal temperature and viscosity for printing.

- Pump: A high-pressure pump propels the ink through the system, ensuring a consistent flow to the printhead.

- Printhead: The heart of the CIJ system, the printhead contains the nozzle that ejects ink droplets and the charge electrode that selectively charges these droplets.

- Deflection Plates: These electrically charged plates steer the ink droplets onto the substrate or into the gutter for recycling.

- Gutter: Collects unused ink droplets and returns them to the ink reservoir for reuse, enhancing efficiency.

- Controller: The brain of the system, responsible for coordinating all components and managing print patterns.

The Printing Process

The CIJ printing process is a marvel of precision engineering:

- Ink Ejection: The pump forces ink through the nozzle, creating a continuous stream of droplets.

- Droplet Charging: As droplets break off from the stream, they pass through a charge electrode, which selectively charges some droplets while leaving others uncharged.

- Deflection: The charged droplets pass between deflection plates, which steer them onto the substrate to form the desired pattern.

- Recycling: Uncharged droplets fall into the gutter and are recycled back into the ink reservoir.

This process occurs at incredibly high speeds, with modern systems capable of generating up to 120,000 droplets per second.

Advanced Features

Contemporary industrial CIJ printing systems incorporate several advanced features that enhance their functionality and ease of use:

- Automatic Cleaning Systems: These systems help prevent nozzle clogging and ensure consistent print quality.

- Viscosity Control: Automated systems maintain optimal ink viscosity for reliable performance across various environmental conditions.

- User-Friendly Interfaces: Touchscreen displays and intuitive software make it easy for operators to adjust settings and manage print jobs.

- Remote Monitoring: Many systems now offer remote monitoring capabilities, allowing for real-time performance tracking and troubleshooting.

By leveraging these advanced features, manufacturers can maximize the efficiency and reliability of their CIJ printing operations.

Applications and Industry-Specific Solutions

The versatility of industrial CIJ printing systems has led to their widespread adoption across numerous industries. These systems offer tailored solutions for various sectors, each with its unique requirements and challenges.

Food and Beverage Industry

In the food and beverage sector, CIJ printing systems play a crucial role in ensuring product safety and traceability:

- Date Coding: Printing expiration dates and best-before information on packaging.

- Lot Numbers: Adding batch codes for quality control and recall management.

- Nutritional Information: Printing variable data such as calorie content or allergen warnings.

CIJ systems in this industry must be capable of high-speed printing to keep up with fast-moving production lines while adhering to strict hygiene standards.

Pharmaceutical and Healthcare

The pharmaceutical industry relies heavily on CIJ printing for regulatory compliance and patient safety:

- Serial Numbers: Printing unique identifiers on medication packaging for anti-counterfeiting measures.

- Expiration Dates: Clearly marking when medications should no longer be used.

- Batch Codes: Enabling traceability throughout the supply chain.

CIJ systems in this sector must deliver exceptional print quality and accuracy to meet stringent regulatory requirements.

Automotive Manufacturing

In the automotive industry, industrial CIJ printing systems are used for various marking applications:

- Part Identification: Printing serial numbers and part codes on components.

- Quality Control: Adding production dates and shift codes for traceability.

- Customization: Marking specific configurations or options on vehicle parts.

The ability of CIJ systems to print on diverse materials, including metals and plastics, makes them invaluable in automotive manufacturing.

Electronics and Semiconductor Industry

CIJ printing systems provide essential marking solutions for electronic components:

- Circuit Board Marking: Printing identification codes on PCBs.

- Component Labeling: Adding serial numbers or product codes to small electronic parts.

- Traceability: Implementing systems for tracking components throughout the assembly process.

The precision and non-contact nature of faith printers are particularly beneficial in this industry, where components are often delicate and sensitive to physical contact.

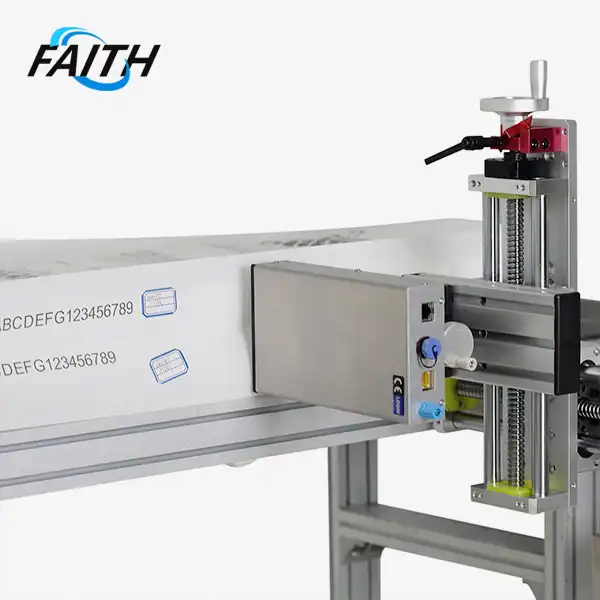

Building Materials and Construction

CIJ systems find applications in marking various building materials:

- Pipe Marking: Adding identification codes and specifications to pipes and conduits.

- Timber Grading: Printing grade markings on lumber products.

- Concrete Products: Marking batch information on concrete blocks or tiles.

The durability of CIJ-printed markings makes them suitable for products that may be exposed to harsh environmental conditions.

FAQ

Q: What makes industrial CIJ printing systems different from other printing technologies?

A: CIJ systems offer non-contact printing, high-speed capabilities, and the ability to print on various surfaces, making them ideal for industrial applications.

Q: How often do CIJ printers require maintenance?

A: Maintenance frequency depends on usage, but modern CIJ systems often have self-cleaning features that reduce the need for manual maintenance.

Q: Can CIJ printers use different types of ink?

A: Yes, CIJ systems can use various ink types, including solvent-based, water-based, and UV-curable inks, depending on the application.

Conclusion

Industrial CIJ printing systems have revolutionized product marking and coding across numerous industries. Their precision, versatility, and reliability make them an indispensable tool in modern manufacturing processes. As technology continues to advance, we can expect even more innovative applications and improvements in CIJ printing capabilities. For more information on China CIJ printers factory and how they can benefit your business, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you find the perfect solution for your production needs.

References

1. Johnson, M. (2022). "The Evolution of Industrial Printing: From Analog to Digital CIJ Systems." Journal of Manufacturing Technology, 45(3), 112-128.

2. Smith, A. & Brown, J. (2021). "Precision and Versatility: A Comprehensive Review of CIJ Printing in Modern Industry." Industrial Engineering Quarterly, 18(2), 75-93.

3. Lee, S. et al. (2023). "Advancements in Ink Formulations for High-Performance CIJ Printing Systems." Progress in Organic Coatings, 167, 106854.

4. García-Pérez, L. (2020). "Integration of CIJ Printing Systems in Industry 4.0 Manufacturing Environments." Robotics and Computer-Integrated Manufacturing, 62, 101885.

5. Wilson, R. & Thompson, E. (2022). "Comparative Analysis of Industrial Marking Technologies: CIJ vs. Laser vs. Thermal Transfer." Journal of Applied Industrial Printing, 9(4), 302-318.

Online Message

Learn about our latest products and discounts through SMS or email

_1732610504844.webp)