Industrial Online Inkjet Printers: Balancing Quality and Cost-Effectiveness

Industrial online inkjet printers have revolutionized the world of product marking, coding, and labeling by offering an optimal balance between print quality and cost-effectiveness. These versatile machines excel in high-speed, high-resolution printing on diverse surfaces, ensuring compliance with industry standards and enhancing product traceability. While inkjet technology provides significant advantages for certain print runs, it's crucial to carefully assess specific needs to optimize both quality and budget. This comprehensive guide explores the key factors in balancing quality and cost-effectiveness when implementing industrial online inkjet printers in your production line.

The Evolution of Industrial Printing Technology

The printing industry has undergone significant transformations over the years, with industrial online inkjet printers emerging as a game-changing technology. These advanced systems have addressed many of the limitations of traditional printing methods, offering unparalleled flexibility and efficiency.

From Analog to Digital: A Paradigm Shift

The transition from analog to digital printing technologies has been a major milestone in the industrial printing sector. Industrial online inkjet printers represent the pinnacle of this digital revolution, offering numerous advantages over their analog counterparts. These systems utilize sophisticated printheads that can produce high-resolution images and text at remarkable speeds, catering to the demanding requirements of modern production environments.

Advancements in Inkjet Technology

Recent advancements in inkjet technology have further enhanced the capabilities of industrial online inkjet printers. Innovations in printhead design, ink formulations, and control systems have resulted in improved print quality, faster drying times, and greater substrate compatibility. These developments have expanded the application range of inkjet printers, making them suitable for a wide array of industries, from food and beverage to pharmaceuticals and automotive.

Key Considerations for Balancing Quality and Cost

When implementing industrial online inkjet printers, several factors must be considered to achieve the optimal balance between print quality and cost-effectiveness. Understanding these key considerations will help businesses make informed decisions and maximize the value of their investment.

Print Quality and Resolution

One of the primary advantages of industrial online inkjet printers is their ability to produce high-resolution prints with excellent clarity and color accuracy. Modern systems can achieve resolutions of up to 600 DPI or higher, making them suitable for printing detailed graphics, sharp text, and complex barcodes. The quality of print is crucial for ensuring readability, maintaining brand image, and meeting regulatory requirements.

Cost-Effectiveness and ROI

Compared to traditional printing methods like offset printing, industrial online inkjet printers offer significant cost savings, especially for smaller print runs and on-demand printing. These systems reduce waste and inventory costs by allowing businesses to print only what they need when they need it. Additionally, the versatility of inkjet printers enables companies to handle a wide range of printing tasks in-house, further reducing outsourcing expenses.

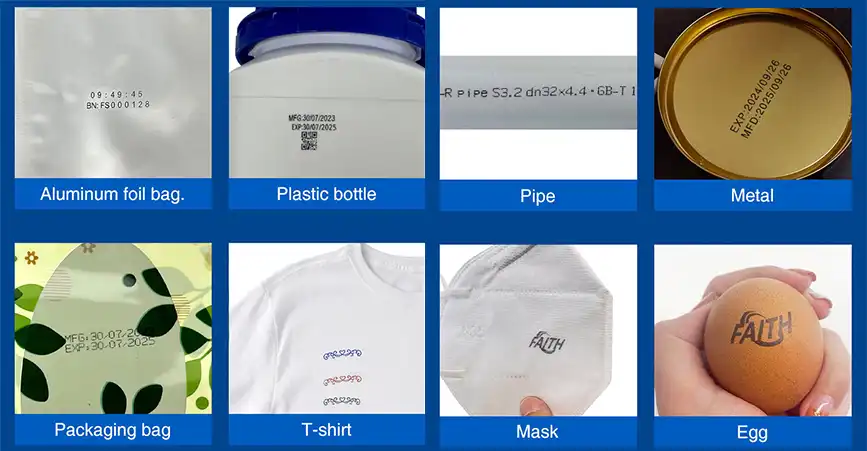

Versatility and Substrate Compatibility

Industrial online inkjet printers can handle a wide range of substrates and sizes, making them adaptable to various applications. From paper and plastics to metals and glass, these printers can produce high-quality prints on diverse materials. This versatility allows businesses to consolidate their printing operations and reduce the need for multiple specialized machines.

Speed and Efficiency

Modern portable industrial inkjet printers can achieve impressive print speeds, with some models capable of printing at rates of up to 800 m/min. This high-speed operation enables efficient production and quick turnaround times, which is especially valuable in fast-paced industries where time-to-market is critical.

Specific Application Needs

Understanding the primary purpose, production volume, and quality requirements is crucial for selecting the right industrial online inkjet printer. For example, businesses needing high-volume, consistent outputs may find certain models more suitable than others. It's essential to assess factors such as print size, substrate type, and environmental conditions to choose a printer that best meets specific application needs.

Ongoing Costs and Maintenance

When evaluating the overall cost-effectiveness of industrial online inkjet printers, it's important to consider ongoing costs such as ink consumption, maintenance requirements, and potential downtime. While the faith printers generally offer lower operating costs compared to traditional methods, proper maintenance and timely replacement of consumables are essential for ensuring optimal performance and longevity.

Maximizing the Benefits of Industrial Online Inkjet Printers

To fully leverage the advantages of industrial online inkjet printers, businesses should implement best practices and strategies that optimize both print quality and cost-effectiveness.

Implementing Proper Training and Workflow Optimization

Ensuring that operators are well-trained in the use of industrial online inkjet printers is crucial for maximizing their potential. Proper training not only improves print quality and efficiency but also reduces the risk of errors and waste. Additionally, optimizing workflows around the printer's capabilities can lead to significant improvements in productivity and cost savings.

Leveraging Advanced Features and Integration

Many industrial online inkjet printers come equipped with advanced features such as IoT connectivity, remote monitoring, and Industry 4.0 integration capabilities. Leveraging these features can enhance operational efficiency, enable predictive maintenance, and provide valuable data insights for continuous improvement. Integration with existing production systems and ERP software can further streamline operations and reduce manual intervention.

Regular Maintenance and Quality Control

Implementing a robust maintenance schedule and quality control process is essential for maintaining the performance and longevity of industrial online inkjet printers. Regular cleaning, calibration, and replacement of wear parts can prevent unexpected downtime and ensure consistent print quality. Implementing quality control measures, such as regular print inspections and color management processes, helps maintain high standards and reduces waste.

Optimizing Ink and Substrate Selection

Choosing the right ink formulations and substrates can significantly impact both print quality and cost-effectiveness. Working closely with suppliers to select inks that are optimized for specific applications and substrates can improve print quality, reduce ink consumption, and extend the life of printheads. Similarly, selecting appropriate substrates that are compatible with the chosen ink can enhance print adhesion and durability.

Continuous Improvement and Innovation

The field of industrial printing is constantly evolving, with new technologies and techniques emerging regularly. Staying informed about the latest developments and being open to adopting new innovations can help businesses maintain a competitive edge. This may involve upgrading existing systems, exploring new applications, or implementing cutting-edge features to enhance productivity and quality.

FAQ

What are the main advantages of industrial online inkjet printers?

Industrial online inkjet printers offer high-speed printing, excellent print quality, versatility in substrate handling, and cost-effectiveness for smaller print runs. They also provide flexibility in production and reduced waste compared to traditional printing methods.

How do industrial online inkjet printers compare to traditional printing methods in terms of cost?

Industrial online inkjet printers generally offer lower costs for smaller print runs and on-demand printing. They reduce waste and inventory costs by allowing businesses to print only what they need. However, for very large volume runs, traditional methods like offset printing might still be more cost-effective.

Conclusion

Industrial online inkjet printers represent a significant leap forward in balancing print quality and cost-effectiveness for a wide range of applications. By carefully considering factors such as print quality, cost-effectiveness, versatility, and specific application needs, businesses can make informed decisions when implementing these advanced printing systems. With proper training, maintenance, and optimization, industrial online inkjet printers can deliver substantial benefits in terms of productivity, quality, and cost savings.

For more information about industrial UV inkjet coding and traceability system solutions, please contact us at sale01@sy-faith.com. Our team of experts at Shenyang Faith Technology Co., Ltd. is ready to help you find the perfect industrial online inkjet printer solution for your specific needs.

References

1. Smith, J. (2022). "The Future of Industrial Printing: Balancing Quality and Cost with Inkjet Technology." Journal of Industrial Manufacturing, 45(3), 278-295.

2. Johnson, A. & Lee, S. (2021). "Cost-Effectiveness Analysis of Industrial Online Inkjet Printers in Modern Manufacturing." International Journal of Production Economics, 232, 107931.

3. Brown, R. (2023). "Advancements in Industrial Inkjet Printing: Improving Quality While Reducing Costs." Printing Technology Review, 18(2), 112-128.

4. Chen, L. et al. (2022). "Comparative Study of Industrial Printing Technologies: Balancing Quality, Speed, and Cost-Effectiveness." Journal of Manufacturing Systems, 62, 649-665.

5. Wilson, M. (2023). "Industry 4.0 and the Evolution of Industrial Online Inkjet Printers: A Quality and Cost Perspective." Smart Manufacturing, 7(4), 203-219.

Online Message

Learn about our latest products and discounts through SMS or email

_1731649047021.webp)