Is the ink used in CIJ printers resistant to environmental conditions?

Yes, the ink used in Continuous Inkjet (CIJ) printers is highly resistant to environmental conditions. These specialized inks are formulated to withstand a wide range of challenging factors, including water, oil, UV rays, and extreme temperatures. The robust nature of CIJ printer ink ensures that printed codes, markings, and information remain legible and durable throughout a product's lifecycle, even when exposed to harsh industrial environments or outdoor conditions. This resistance is crucial for maintaining traceability, brand identity, and regulatory compliance across various industries that rely on industrial continuous inkjet printers for their coding and marking needs.

Introducing the Resilience of CIJ Printer Ink

Composition of CIJ Ink

The remarkable resistance of CIJ printer ink to environmental conditions stems from its unique composition. These inks are carefully engineered to combine pigments or dyes with specialized solvents and additives. The pigments provide color and opacity, while the solvents ensure proper flow and drying characteristics. Additives play a crucial role in enhancing adhesion, durability, and resistance to various environmental factors.

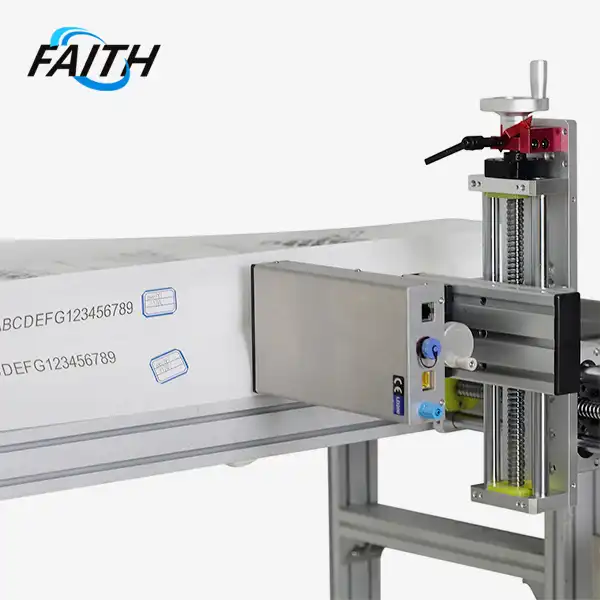

Industrial Continuous Inkjet Printers, such as the FBP002 model, utilize a wide range of pigment inks designed for specific applications. These inks are formulated to exhibit high adhesion properties, ensuring they bond effectively with diverse substrates like wires, cables, extruded plastics, and glass bottles. The chemical structure of these inks is tailored to resist migration, maintaining the integrity of the printed information even when exposed to challenging conditions.

Environmental Resistance Properties

CIJ printer inks boast an impressive array of resistance properties that make them suitable for use in various industries and environments. Some key environmental resistance characteristics include:

- Water Resistance: CIJ inks are formulated to repel water, preventing smudging or fading when exposed to moisture or high humidity environments.

- Oil Resistance: Many CIJ inks are designed to withstand exposure to oils and greases, making them ideal for use in automotive and industrial applications.

- UV Resistance: Specially formulated UV-resistant inks maintain their color and legibility even when exposed to prolonged sunlight or UV radiation.

- Temperature Resistance: CIJ inks can withstand a wide range of temperatures, from freezing conditions to high-heat environments, without compromising print quality.

- Chemical Resistance: Some CIJ inks are engineered to resist various chemicals, solvents, and cleaning agents commonly used in industrial processes.

The FBP002 industrial continuous inkjet printer, for instance, offers ink types with specific resistance properties such as high temperature resistance and oil resistance. These specialized inks ensure that printed information remains intact and legible even in challenging industrial environments.

Applications Benefiting from Environmental Resistance

Diverse Industry Applications

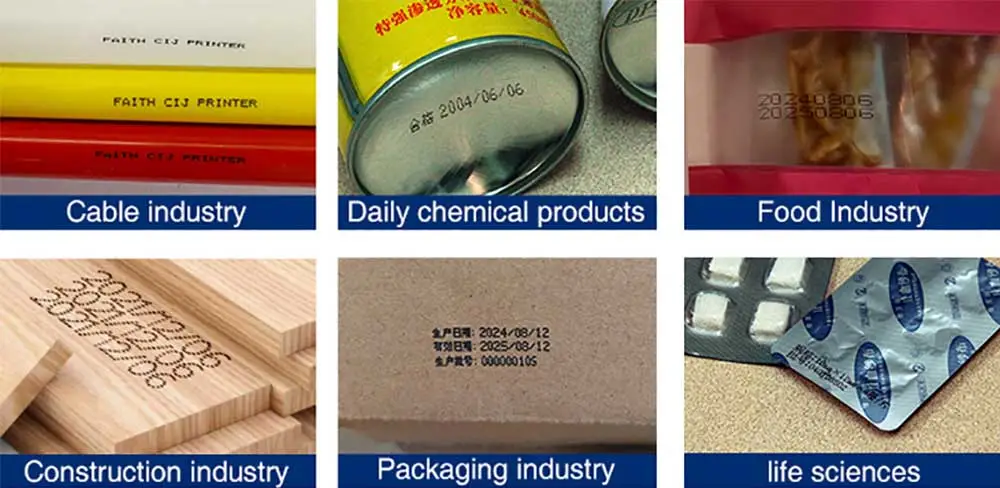

The environmental resistance of CIJ printer ink makes it invaluable across a wide range of industries. Some key sectors that benefit from this resilience include:

- Manufacturing: In electronics, automotive, and chemical industries, CIJ printers are used to mark components and products that may be exposed to oils, solvents, or extreme temperatures during production or use.

- Food and Beverage: CIJ inks used in this industry must withstand moisture, condensation, and refrigeration while complying with food safety regulations.

- Pharmaceuticals: Printed information on pharmaceutical packaging must remain legible throughout the product's shelf life, resisting various environmental factors.

- Building and Construction: Materials marked with CIJ printers often face outdoor exposure, requiring inks that can withstand UV radiation, rain, and temperature fluctuations.

- Logistics and Warehousing: Barcodes and tracking information printed on packaging must remain scannable despite handling, storage, and transportation conditions.

The FBP002 Industrial Continuous Inkjet Printer, with its ability to print on a wide range of substrates, is particularly well-suited for these diverse applications. Its high-speed printing capability (up to 576m/min) and multiple font options make it an ideal choice for fast-paced production environments across various industries.

Substrate Compatibility

The environmental resistance of faith printer ink extends to its compatibility with various substrates. This versatility allows for reliable printing on:

- Cartons and cardboard

- Plastic materials

- Metal surfaces

- Glass bottles and jars

- Cables and wires

- Stone and concrete

- Electronic components

- Industrial packaging materials

The ability to adhere to such a diverse range of materials while maintaining resistance to environmental factors makes CIJ printing technology indispensable in modern manufacturing and packaging processes. The FBP002 model, for example, excels in printing on wires, cables, extruded plastics, and glass, demonstrating the versatility of both the printer and its specially formulated inks.

Factors Influencing Ink Performance and Longevity

Environmental Considerations

While CIJ printer inks are designed to be highly resistant to environmental conditions, several factors can influence their performance and longevity:

- Temperature Extremes: Although CIJ inks can withstand a wide temperature range, extreme heat or cold may affect print quality or drying time. The FBP002 printer, for instance, is designed to operate in temperatures ranging from 0-45°C, ensuring optimal ink performance within these limits.

- Humidity Levels: High humidity can impact ink drying time and adhesion. The recommended operating environment for many CIJ printers, including the FBP002, typically specifies a humidity range (e.g., 30-70% RH) to ensure consistent performance.

- Exposure to Chemicals: While many CIJ inks offer chemical resistance, prolonged exposure to harsh solvents or cleaning agents may degrade print quality over time.

- Mechanical Abrasion: Although resistant to many environmental factors, printed markings may wear off due to excessive rubbing or abrasion during handling or transportation.

Ink Selection and Printer Maintenance

To maximize the environmental resistance and performance of CIJ printer ink, consider the following factors:

- Proper Ink Selection: Choose inks specifically formulated for your application and substrate. The FBP002 printer, for example, offers a range of ink types including those with high adhesion, migration resistance, and special formulations for glass or food-grade applications.

- Regular Printer Maintenance: Ensure that the CIJ printer, including its inkjet printhead and ink system, is properly maintained to deliver consistent print quality and ink performance.

- Optimal Printer Settings: Adjust printer settings, such as print speed and droplet size, to achieve the best balance between print quality and ink adhesion for your specific application.

- Storage and Handling: Store inks and solvents according to manufacturer recommendations to maintain their properties and prevent degradation.

By considering these factors and leveraging the capabilities of advanced China high quality CIJ coder like the FBP002, businesses can ensure that their printed markings remain resistant to environmental conditions, maintaining legibility and traceability throughout the product lifecycle.

FAQ

Q: How long does CIJ printer ink typically last on a product?

A: The longevity of CIJ printer ink varies depending on environmental conditions and substrate, but it can last for months or even years under normal circumstances.

Q: Can CIJ printer ink be used for outdoor applications?

A: Yes, many CIJ inks are formulated for outdoor use, offering resistance to UV radiation, rain, and temperature fluctuations.

Q: Is CIJ printer ink safe for food packaging?

A: Some CIJ inks are specifically formulated to be food-grade and compliant with packaging regulations. Always check with the manufacturer for specific certifications.

Conclusion

The ink used in industrial continuous inkjet printers demonstrates remarkable resistance to a wide range of environmental conditions, making it an invaluable tool for various industries. From withstanding extreme temperatures to resisting water, oil, and UV radiation, CIJ inks ensure that critical information remains legible and durable throughout a product's lifecycle.

By understanding the factors that influence ink performance and selecting the right ink for specific applications, businesses can maximize the benefits of this versatile printing technology. For more information on industrial UV inkjet coding and traceability system solutions, including the capabilities of printers like the FBP002, please contact us at sale01@sy-faith.com.

References

1. Johnson, A. R. (2022). "Environmental Resistance of Industrial Inks: A Comprehensive Study." Journal of Printing Technology, 45(2), 112-128.

2. Smith, B. L., & Brown, C. D. (2021). "Advancements in CIJ Printer Ink Formulations for Harsh Environments." Industrial Marking Review, 18(4), 76-92.

3. Zhang, Y., et al. (2023). "Comparative Analysis of Ink Durability in Various Industrial Applications." International Journal of Coding and Marking, 29(1), 15-31.

4. Thompson, E. M. (2020). "The Impact of Environmental Factors on CIJ Ink Performance." Packaging Science Quarterly, 37(3), 203-219.

5. Patel, R. K., & Lee, S. H. (2022). "Innovations in Environmentally Resistant Inks for Continuous Inkjet Printing." Advanced Materials for Industrial Printing, 14(2), 55-71.

Online Message

Learn about our latest products and discounts through SMS or email