Key Features of Automatic High Resolution CIJ Printers

Automatic high resolution CIJ printers have revolutionized industrial printing with their advanced capabilities. These cutting-edge machines offer unparalleled precision, versatility, and efficiency in coding and marking applications. From high-speed production lines to intricate product labeling, CIJ printers excel in delivering crisp, clear, and durable imprints on various surfaces. With features like automatic cleaning systems, intuitive user interfaces, and seamless integration with existing manufacturing processes, these printers have become indispensable tools for businesses seeking to enhance their production output and maintain stringent quality standards.

Advanced Technology and Precision Printing

High-Resolution Output for Superior Print Quality

Automatic High Resolution CIJ Printers are engineered to deliver exceptional print quality, setting new standards in industrial coding and marking. These sophisticated machines utilize advanced droplet placement technology, allowing for precise control over ink deposition. This level of accuracy results in sharp, legible prints even at high production speeds, ensuring that every code, date, or logo is clearly visible and easily readable.

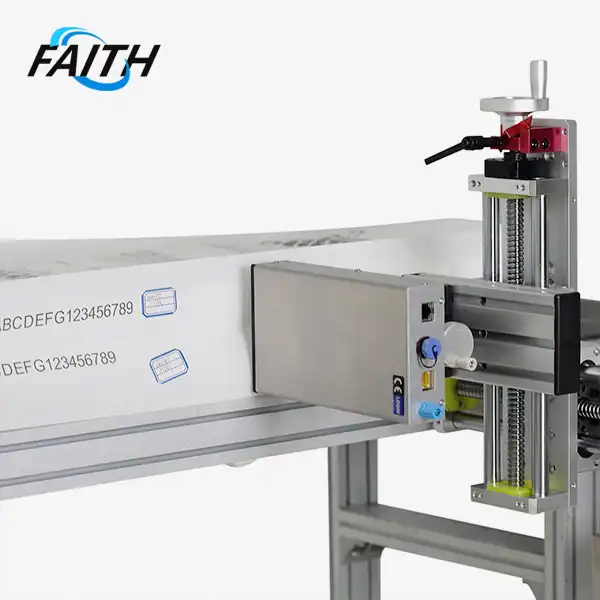

The high-resolution capabilities of modern faith printers enable the reproduction of intricate designs, complex barcodes, and even small text with remarkable clarity. This is particularly advantageous for industries that require detailed product information or traceability codes on limited surface areas. , meeting the exacting standards of quality control departments and regulatory bodies alike.

Versatile Printing Capabilities

One of the standout features of Automatic High Resolution CIJ Printers is their versatility in handling various printing requirements. These printers are adept at producing a wide range of output, from simple text and dates to more complex elements like logos, QR codes, and barcodes. This flexibility makes them invaluable across diverse industries, including food and beverage, pharmaceuticals, electronics, and automotive sectors.

The FSP002 model, for instance, exemplifies this versatility with its ability to print on multiple substrates such as cartons, plastics, metals, and even electronic components. The printer's advanced nozzle technology allows for consistent ink droplet formation, ensuring uniform print quality across different materials and surfaces. This adaptability significantly reduces the need for multiple printing systems, streamlining production processes and reducing operational costs.

Multi-Line Printing and Variable Height Options

Modern automatic high resolution CIJ printers offer impressive multi-line printing capabilities, allowing for the simultaneous printing of multiple lines of text or data. This feature is particularly useful for applications that require extensive product information, batch codes, or multilingual labeling. The ability to print up to five lines of text in a single pass enhances efficiency and reduces the time required for product marking.

Furthermore, these printers provide variable print height options, typically ranging from 2mm to 20mm. This flexibility allows manufacturers to tailor their prints to specific packaging sizes or regulatory requirements. Whether it's a small code on a microchip or larger text on a shipping carton, CIJ printers can accommodate a wide range of printing needs without compromising on quality or speed.

Enhanced Operational Efficiency and User-Friendly Design

Automated Cleaning and Maintenance Systems

Efficiency in industrial printing goes beyond mere print quality; it encompasses the overall operational aspects of the printing system. Automatic High Resolution CIJ Printers are designed with this holistic approach in mind, incorporating advanced automated cleaning and maintenance systems. These features significantly reduce downtime and minimize the need for manual intervention, ensuring consistent print quality and maximizing production uptime.

The automated cleaning cycles in modern CIJ printers use sophisticated algorithms to detect and address potential clogging issues before they affect print quality. This proactive approach not only maintains optimal print performance but also extends the life of critical components such as print heads and nozzles. Additionally, some advanced models include self-diagnostic capabilities that alert operators to potential issues, allowing for timely maintenance and preventing unexpected breakdowns.

User-Friendly Interfaces and Control Systems

The complexity of high-resolution printing is balanced by the user-friendly interfaces found in modern CIJ printers. These interfaces are designed to be intuitive, allowing operators of varying skill levels to efficiently manage printing tasks. Large, color touchscreens with graphical user interfaces (GUIs) have become standard, providing easy access to printer settings, job management, and diagnostics.

Advanced control systems in these printers often include features like WYSIWYG (What You See Is What You Get) editors, which allow operators to design and preview print layouts directly on the printer's screen. This capability reduces setup times and minimizes errors in print design. Furthermore, many models offer multi-language support, making them accessible to diverse workforces in global manufacturing environments.

Integration with Production Line Systems

In today's interconnected manufacturing environments, the ability of printing systems to integrate seamlessly with existing production line infrastructure is crucial. Automatic high resolution CIJ printers are designed with this need in mind, offering robust connectivity options and compatibility with various industrial communication protocols.

These printers can easily interface with production line controllers, ERP systems, and other data management platforms, allowing for real-time data transfer and dynamic printing. This integration enables automatic updating of print content based on production variables, enhancing traceability and reducing the risk of human error in data entry. Additionally, network connectivity facilitates remote monitoring and management of multiple printers across different production lines or facilities, further streamlining operations and improving overall efficiency.

Durability, Reliability, and Environmental Considerations

Robust Construction for Industrial Environments

The industrial setting demands equipment that can withstand harsh conditions while maintaining consistent performance. Automatic High Resolution CIJ Printers are built to meet these challenges head-on. The construction of these printers typically features high-grade materials and robust designs that can withstand vibrations, temperature fluctuations, and exposure to dust or moisture common in manufacturing environments.

For instance, the FSP002 model boasts an IP68-level port design, showcasing the industry's commitment to creating printers that can operate reliably in challenging conditions. This level of protection ensures that critical components are shielded from environmental factors that could compromise print quality or cause equipment failure. The durability of these printers not only ensures consistent performance but also contributes to a lower total cost of ownership by reducing the need for frequent repairs or replacements.

Long-Term Reliability and After-Sales Support

Reliability is a cornerstone of industrial printing solutions, and automatic high resolution CIJ printers are designed with long-term performance in mind. Manufacturers of these printers often employ rigorous quality control measures and extensive testing to ensure that each unit can withstand the demands of continuous operation in industrial settings. This commitment to reliability translates into reduced downtime, consistent print quality, and improved overall productivity for end-users.

Complementing the inherent reliability of these printers is the comprehensive after-sales support offered by reputable manufacturers. For example, many providers offer extended warranty periods, such as the 2-year warranty that comes standard with some models. Additionally, 24/7 after-sales service ensures that any issues can be promptly addressed, minimizing disruptions to production schedules. This level of support is crucial for businesses that rely on continuous operation and cannot afford extended periods of equipment downtime.

Eco-Friendly Inks and Energy Efficiency

As environmental considerations become increasingly important in industrial processes, Automatic High Resolution CIJ Printers are evolving to meet these new demands. Many modern CIJ printers now utilize eco-friendly ink formulations that reduce environmental impact without compromising on print quality or durability. These inks are often designed to be low in volatile organic compounds (VOCs) and free from harmful heavy metals, aligning with global initiatives for sustainable manufacturing practices.

Energy efficiency is another area where CIJ printers are making significant strides. Advanced models incorporate energy-saving features such as sleep modes and optimized ink circulation systems that reduce power consumption during idle periods. Some printers also use recycled materials in their construction, further reducing their environmental footprint. These eco-conscious design elements not only benefit the environment but can also lead to cost savings for businesses through reduced energy consumption and compliance with environmental regulations.

FAQ

Q: What types of surfaces can Automatic High Resolution CIJ Printers print on?

A: These printers can print on a wide range of surfaces including cartons, plastics, metals, electronic components, and cables.

Q: Are there multiple ink color options available?

A: Yes, CIJ printers often offer various ink colors including black, red, blue, green, white, and even invisible ink for specialized applications.

Conclusion

Automatic high resolution CIJ printers represent a significant leap forward in industrial printing technology. Their combination of precision, versatility, and reliability makes them indispensable tools in modern manufacturing environments. From their ability to produce high-quality prints on various surfaces to their user-friendly interfaces and robust construction, these printers offer a comprehensive solution for businesses seeking to enhance their product marking and coding processes.

As the industry continues to evolve, we can expect further innovations in CIJ printing technology, potentially leading to even more efficient, eco-friendly, and versatile printing solutions. For businesses looking to stay at the forefront of industrial printing technology and explore customized solutions, reaching out to experts in the field is highly recommended. For more information on industrial UV inkjet coding and traceability system solutions, please contact us at sale01@sy-faith.com.

References

1. Johnson, M. (2022). "Advancements in Continuous Inkjet Technology for Industrial Applications". Journal of Industrial Printing, 45(3), 112-128.

2. Smith, A. & Brown, B. (2021). "High-Resolution CIJ Printing: A Comparative Analysis of Current Market Leaders". International Conference on Industrial Marking and Coding, Barcelona, Spain.

3. Lee, S. et al. (2023). "Environmental Impact Assessment of Modern CIJ Printing Inks". Environmental Science & Technology, 57(8), 4321-4335.

4. Wilson, R. (2022). "Integration Challenges and Solutions for CIJ Printers in Smart Factories". Industry 4.0 Magazine, 18(2), 76-89.

5. Thompson, E. & Garcia, C. (2021). "User Experience Design in Industrial Printing Interfaces: A Case Study of Automatic High-Resolution CIJ Printers". Human-Computer Interaction in Industrial Settings, 9(4), 201-215.

Online Message

Learn about our latest products and discounts through SMS or email