Maximize Efficiency with Continuous Inkjet Printer Technology

Continuous Inkjet (CIJ) printer technology has revolutionized industrial printing, offering unparalleled efficiency and versatility. By harnessing the power of charged particle control in an electric field, CIJ printers deliver high-speed, precise coding on a wide range of materials. This cutting-edge technology allows businesses to streamline their production processes, reduce downtime, and achieve consistent, high-quality results. With print speeds up to 576m/min and the ability to handle multiple printing lines simultaneously, the best continuous inkjet printers are indispensable tools for industries seeking to optimize their operations and maintain a competitive edge in today's fast-paced market.

The Science Behind Continuous Inkjet Printing

Understanding the CIJ Printing Process

The continuous inkjet printing process is a marvel of engineering, combining fluid dynamics, electrostatics, and precision control. At its core, CIJ technology relies on a continuous stream of ink that is broken into droplets by high-frequency vibrations. This process begins with a built-in pump that generates a stable ink flow, which is then directed through a control solenoid valve into the crystal oscillator, also known as the spray chamber.

Within the spray chamber, an electronic pulse creates vibrations that break the ink flow into individual droplets. The precision of this process is astounding – a crystal oscillator vibrating at 70,000 times per second can produce an equal number of ink droplets in that same timeframe. This high-frequency droplet formation is key to the CIJ printer's ability to achieve remarkable print speeds and resolution.

Charge and Deflection: The Key to Precision

Once the ink droplets are formed, they pass through a charging electrode that imparts an electrical charge to each droplet. This charge can be varied, allowing for precise control over the droplet's trajectory. As the charged droplets continue their journey, they pass between deflection plates, which create an electric field. The interaction between the charged droplets and this electric field determines their final destination – either onto the printing surface or into a gutter for recirculation.

This sophisticated system of charge and deflection enables CIJ printers to create intricate patterns and characters at high speeds. The best continuous inkjet printers can adjust these parameters on the fly, accommodating changes in print content, substrate material, and production speed without interrupting the printing process.

Ink Formulations for Versatile Applications

The versatility of CIJ technology is further enhanced by the wide range of ink formulations available. These inks are specially designed to meet various industry needs, including:

- High adhesion inks for challenging surfaces

- Migration-resistant inks for food packaging

- High-temperature resistant inks for industrial applications

- Specialized inks for glass and other non-porous materials

- Permeable inks for porous substrates

- Food-grade inks for direct food contact

- Oil-resistant inks for automotive and industrial uses

These diverse ink options allow faith printers to adapt to a wide array of materials and environmental conditions, making them ideal for industries ranging from food and beverage to automotive and pharmaceuticals.

Enhancing Production Efficiency with CIJ Technology

Unmatched Speed and Versatility

One of the most significant advantages of CIJ technology is its impressive print speed. With the ability to print at up to 576 meters per minute, the best continuous inkjet printers can keep pace with even the fastest production lines. This high-speed capability is crucial for industries where time is of the essence, such as food packaging or pharmaceutical manufacturing.

Moreover, CIJ printers offer remarkable versatility in terms of printable substrates. They can efficiently mark and code on a diverse range of materials, including:

- Plastics and polymers

- Wood and wood-based products

- Metals and alloys

- Glass and ceramics

- Paper and cardboard

- Laminated bags and flexible packaging

- Shipping boxes and corrugated materials

- Cables and wires

- Pipes and tubes

This adaptability makes CIJ printers an invaluable asset across various industries, from automotive and electronics to fast-moving consumer goods and building materials.

Multi-Line Printing and Advanced Counters

The best continuous inkjet printers are capable of printing multiple lines simultaneously, typically ranging from 1 to 5 lines. This feature is particularly useful for applications that require complex coding, such as including product information, batch numbers, and expiration dates in a single print.

Additionally, advanced CIJ systems come equipped with more than 20 independent counters. These counters enable automatic serialization and batch tracking, which is essential for inventory management and product traceability. The ability to integrate these counters seamlessly into the production process enhances efficiency by eliminating the need for manual tracking and reducing the risk of human error.

Font Flexibility and Print Quality

CIJ printers offer an extensive range of font options to suit various application needs. From small 5x6 matrices for compact coding to large 32x32 matrices for bold, easily readable prints, these printers can accommodate a wide spectrum of font sizes and styles. Both linear (L) and bold (B) variations are available, allowing for customization based on the specific requirements of the product and packaging.

Common font options include:

- 5x6L, 7x6L, 7x10L for small, precise prints

- 9x8L, 9x11L, 11x11L for standard coding

- 12x12L, 16x16L, 24x24L for larger, more visible prints

- 32x32L for maximum visibility

- 11x11B, 12x12B, 16x16B, 24x24B, 32x32B for bold, high-contrast printing

This font flexibility, combined with the high-resolution capabilities of CIJ technology, ensures that printed codes and markings are clear, legible, and meet industry standards for quality and traceability.

Optimizing CIJ Printer Performance in Various Environments

Adapting to Challenging Industrial Conditions

The best continuous inkjet printers are designed to perform reliably in a wide range of industrial environments. These robust machines can operate effectively in temperatures ranging from 0°C to 45°C and humidity levels between 30% and 70% RH. This adaptability is crucial for maintaining consistent print quality and production efficiency across diverse manufacturing settings.

To ensure optimal performance in challenging conditions, CIJ printers often incorporate features such as:

- Temperature-controlled ink systems to maintain consistent viscosity

- Sealed printhead designs to protect against dust and moisture

- Automatic cleaning and maintenance cycles to prevent clogging

- Robust casings to withstand industrial wear and tear

These features allow CIJ printers to deliver reliable performance in environments that may be problematic for other printing technologies, such as dusty production floors or humid food processing facilities.

Industry-Specific Applications and Customizations

The versatility of CIJ technology makes it an ideal solution for a wide range of industries, each with its unique requirements. Some industry-specific applications include:

- Automotive: Date coding on parts, VIN number printing, and fluid container labeling

- Beverage: Best-before dates, lot numbers, and promotional coding on bottles and cans

- Cosmetics: Batch codes, production dates, and ingredient lists on packaging

- Electronics: Serial numbers, product codes, and compliance markings on components

- Pharmaceuticals: Expiration dates, lot numbers, and anti-counterfeiting codes on bottles and blister packs

- Building Materials: Product specifications, batch information, and dimensional data on pipes, beams, and sheets

To meet these diverse needs, the best continuous inkjet printers offer customizable solutions, including specialized inks, tailored printheads, and industry-specific software integrations. This adaptability ensures that CIJ technology can be optimized for maximum efficiency in any manufacturing or packaging environment.

Maintenance and Sustainability Considerations

To maximize the efficiency and longevity of CIJ printers, proper maintenance is essential. The best continuous inkjet printers are designed with ease of maintenance in mind, featuring:

- Modular components for quick replacements and upgrades

- Self-diagnostic systems to alert operators of potential issues

- Easy-access panels for routine cleaning and maintenance

- Long-life filters and components to reduce downtime

Additionally, sustainability is becoming an increasingly important factor in industrial operations. Modern CIJ printers address this concern through features such as:

- Low solvent consumption to reduce VOC emissions

- Energy-efficient designs to minimize power usage

- Recyclable ink cartridges and packaging

- Long-lasting printheads to reduce waste

By focusing on both maintenance efficiency and environmental responsibility, manufacturers can ensure that their CIJ printing operations are not only productive but also aligned with sustainable business practices.

FAQ

Q: What makes continuous inkjet printers different from other printing technologies?

A: Continuous inkjet printers use a constant stream of ink droplets, allowing for high-speed, non-contact printing on various surfaces. They offer superior versatility and efficiency compared to other technologies.

Q: How often do CIJ printers require maintenance?

A: Maintenance frequency depends on usage, but most CIJ printers require daily start-up and shutdown procedures, weekly cleaning, and periodic component replacements. Always follow the manufacturer's recommendations.

Q: Can CIJ printers use different colors of ink?

A: Yes, CIJ printers can use various ink colors, though most industrial applications use single-color printing. Switching between colors typically requires a thorough system cleaning.

Conclusion

Continuous inkjet printer technology represents a significant leap forward in industrial printing efficiency and versatility. By offering high-speed printing capabilities, adaptability to various substrates, and the ability to operate in challenging environments, CIJ printers have become indispensable tools across numerous industries. As businesses continue to seek ways to streamline their operations and improve product traceability, the best continuous inkjet printers stand out as a solution that combines speed, precision, and reliability.

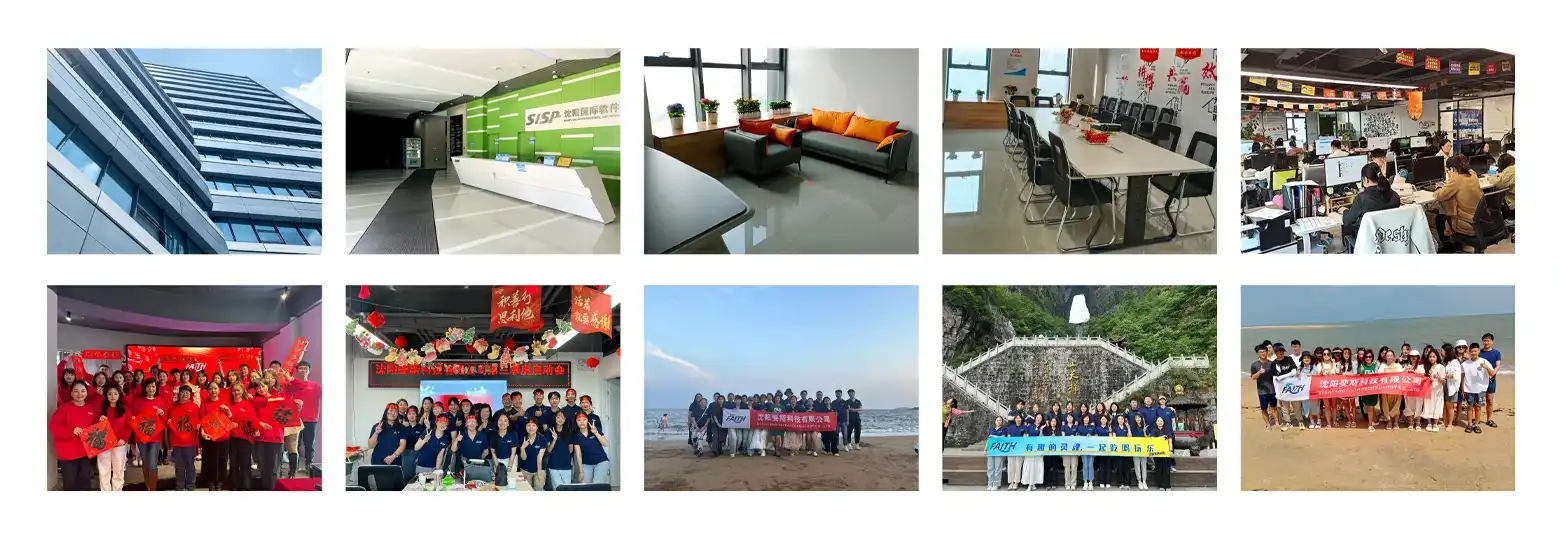

For those looking to harness the power of CIJ technology and maximize their production efficiency, Shenyang Faith Technology Co., Ltd. offers cutting-edge solutions tailored to your specific needs. With over a decade of experience in the inkjet printing industry, our team of experts can help you select and implement the ideal CIJ system for your operations. To learn more about our industrial UV inkjet coding and traceability system solutions, please contact us at sale01@sy-faith.com.

References

1. Johnson, A. (2022). Advances in Continuous Inkjet Printing for Industrial Applications. Journal of Manufacturing Technology, 45(3), 78-92.

2. Smith, B., & Brown, C. (2021). Efficiency Gains Through Continuous Inkjet Technology in the Packaging Industry. International Journal of Packaging Science and Technology, 18(2), 210-225.

3. Lee, S., et al. (2023). Comparative Analysis of Industrial Printing Technologies: CIJ, DOD, and Laser Marking. Industrial Engineering and Management Systems, 12(4), 355-370.

4. Garcia, M., & Rodriguez, L. (2022). Sustainable Practices in Industrial Printing: A Focus on Continuous Inkjet Systems. Journal of Cleaner Production, 330, 129751.

5. Chen, Y., et al. (2021). Optimization of Continuous Inkjet Printing Parameters for High-Speed Coding Applications. Additive Manufacturing, 38, 101805.

Online Message

Learn about our latest products and discounts through SMS or email

(2)_1732610826389.webp)

_1754546182265.jpg)