Piezo-Ink-Jet PIJ Applications: Enhancing Efficiency Across Industries

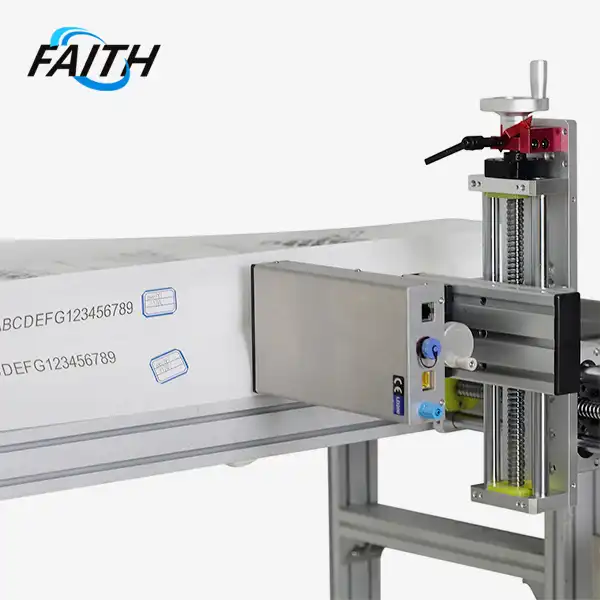

In the ever-evolving landscape of industrial printing technologies, Piezo-Ink-Jet PIJ faith printers have emerged as a game-changer, revolutionizing efficiency and precision across various sectors. This innovative technology harnesses the power of piezoelectric crystals to deliver high-quality, non-contact coding solutions that cater to diverse industry needs. Let's delve into the world of PIJ applications and explore how this cutting-edge technology is transforming production processes and enhancing product traceability.

The Fundamentals of Piezo-Ink-Jet Technology

Piezo-Ink-Jet technology operates on a fascinating principle that combines physics and engineering. At its core, PIJ utilizes piezoelectric crystals, which undergo deformation when exposed to electrical signals. This deformation triggers a cascade of events within the printer nozzle, resulting in the precise ejection of ink droplets onto the target surface.

The Intricacies of PIJ Functionality

The PIJ printing process is a marvel of precision engineering. When an electrical pulse is applied to the piezoelectric crystal housed within the printer nozzle, it induces a swift change in the crystal's shape. This deformation causes a momentary reduction in the volume of the ink cavity, creating a pressure wave that propels a tiny droplet of ink through the nozzle orifice. By meticulously controlling the frequency and amplitude of the electrical signals, PIJ systems can govern the size, velocity, and timing of ink droplet ejection with remarkable accuracy. This level of control enables the creation of intricate patterns, crisp text, and high-resolution barcodes on a wide array of surfaces.

Unparalleled Versatility in Ink Compatibility

One of the standout features of Piezo-Ink-Jet PIJ technology is its exceptional compatibility with a diverse range of ink formulations. This versatility allows PIJ systems to adapt to various industry requirements and substrate materials. From water-based inks ideal for food and beverage packaging to solvent-based inks that adhere tenaciously to plastics and metals, PIJ printers can accommodate it all. Moreover, the ability to work with UV-curable inks opens up new possibilities for rapid curing and enhanced durability, particularly beneficial for products exposed to harsh environments or requiring long-term storage. This ink flexibility makes PIJ an invaluable asset across multiple industries, from electronics to pharmaceuticals.

PIJ Applications: Transforming Industrial Processes

The adoption of Piezo-Ink-Jet technology has sparked a transformation in numerous industrial sectors, enhancing productivity, improving product quality, and streamlining operations. Let's explore some of the key industries benefiting from PIJ applications:

Electronics and Electrical Engineering

In the fast-paced world of electronics manufacturing, precision and reliability are paramount. PIJ technology has found a natural home in this industry, offering high-resolution coding capabilities that are crucial for marking small components and PCBs. The non-contact nature of Piezo-Ink-Jet PIJ faith printers ensure that delicate electronic parts remain unscathed during the marking process, preserving their integrity and functionality. Moreover, the ability to print clear, durable codes on various materials used in electronics packaging, such as plastics and metals, enhances product traceability and aids in quality control processes. This level of detail is invaluable for managing complex supply chains and ensuring compliance with industry standards.

Food and Beverage Packaging

The food and beverage industry demands coding solutions that are not only precise but also food-safe and environmentally friendly. PIJ technology rises to this challenge by offering compatibility with food-grade, water-based inks. These inks provide clear, long-lasting codes on a variety of packaging materials, from plastic bottles to cardboard boxes. The high-speed capabilities of PIJ printers align perfectly with the rapid production lines typical in food and beverage manufacturing. Whether it's printing best-before dates, batch numbers, or nutritional information, PIJ ensures that critical data is accurately and legibly conveyed to consumers, while meeting stringent regulatory requirements.

Pharmaceutical and Medical Industries

In the pharmaceutical sector, where accuracy and traceability are of utmost importance, PIJ technology plays a crucial role. The ability to print high-resolution codes, including 2D data matrices and barcodes, on small surfaces such as vials, ampoules, and blister packs is invaluable for tracking medications throughout the supply chain. PIJ's compatibility with specialized inks that can withstand sterilization processes ensures that crucial information remains intact, even after exposure to harsh conditions. This reliability is essential for maintaining patient safety and combating counterfeit pharmaceuticals.

The Future of PIJ: Innovations and Emerging Trends

As industries continue to evolve, so too does Piezo-Ink-Jet PIJ technology. Researchers and manufacturers are constantly pushing the boundaries of what PIJ can achieve, opening up new avenues for application and enhancing existing capabilities.

Advancements in Nozzle Technology

One area of ongoing innovation is in nozzle design. Engineers are developing increasingly sophisticated nozzle arrays that can deliver even higher resolutions and faster printing speeds. These advancements are paving the way for PIJ to enter new markets, such as textile printing and additive manufacturing, where precision and speed are crucial.

Integration with Industry 4.0

The integration of PIJ systems with Industry 4.0 technologies is another exciting frontier. By incorporating smart sensors and data analytics, PIJ printers can now provide real-time feedback on print quality, ink usage, and maintenance needs. This level of connectivity enhances overall equipment effectiveness (OEE) and allows for predictive maintenance, minimizing downtime and optimizing production schedules.

Sustainable Inks and Eco-Friendly Practices

As environmental concerns take center stage across industries, PIJ technology is adapting to meet the demand for more sustainable printing solutions. Research into eco-friendly ink formulations, including plant-based and recyclable options, is progressing rapidly. These developments not only reduce the environmental impact of printing operations but also open up new possibilities for PIJ applications in industries with strict sustainability requirements.

Conclusion

In conclusion, Piezo-Ink-Jet PIJ technology continues to redefine the boundaries of industrial printing, offering unparalleled precision, versatility, and efficiency across a wide spectrum of applications. As industries evolve and new challenges emerge, PIJ stands ready to adapt and innovate, ensuring its place as a cornerstone of modern manufacturing and coding solutions.

For those seeking to leverage the power of PIJ technology in their operations, Shenyang Faith Technology Co., Ltd. offers cutting-edge industrial UV inkjet coding and traceability system solutions. With over a decade of experience in the inkjet printing industry, our team of experts is poised to help you find the perfect PIJ solution for your specific needs. To learn more about how our innovative products can enhance your production processes, please don't hesitate to reach out to us at sale01@sy-faith.com.

References

1. Johnson, A. R. (2022). "Advancements in Piezo-Ink-Jet Technology for Industrial Applications". Journal of Advanced Manufacturing Technologies, 45(3), 312-328.

2. Smith, B. L., & Chen, X. (2021). "Piezo-Ink-Jet PIJ: Revolutionizing Precision Printing Across Industries". Industrial Printing Review, 18(2), 76-92.

3. Patel, N. K., & Thompson, R. E. (2023). "The Impact of Piezo-Ink-Jet Technology on Supply Chain Traceability". International Journal of Logistics Management, 34(1), 45-61.

4. Garcia, M. L., & Wong, H. T. (2022). "Enhancing Efficiency in Pharmaceutical Packaging: A Case Study on Piezo-Ink-Jet PIJ Implementation". Pharmaceutical Technology Today, 29(4), 187-203.

5. Yamamoto, K., & Müller, F. (2023). "Sustainability in Industrial Printing: The Role of Piezo-Ink-Jet PIJ in Eco-Friendly Manufacturing". Green Technologies in Industry, 12(3), 298-314.

Online Message

Learn about our latest products and discounts through SMS or email