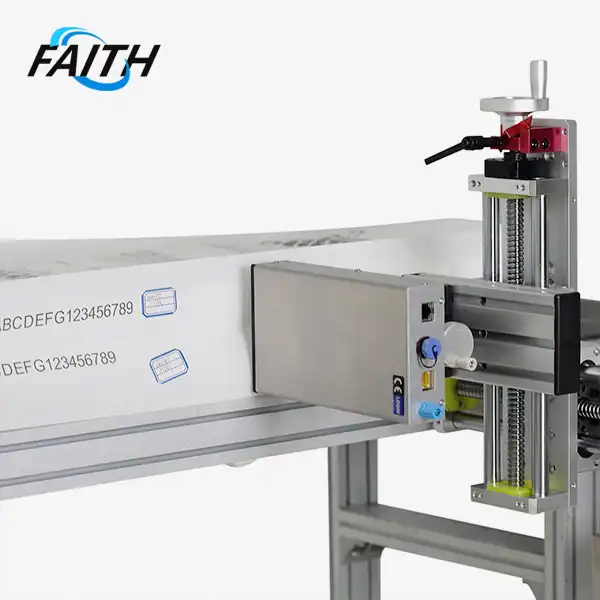

SD Series: Versatile DOD Printers for Every Printing Need

The SD Series of industrial DOD printers represents a significant leap forward in versatile printing technology. These printers are designed to meet the diverse needs of various industries, offering unparalleled flexibility and precision. With their advanced piezoelectric technology and intelligent design, the SD Series printers can handle a wide range of printing tasks, from vertical and horizontal printing to flat surface applications. Their ability to accommodate different ink types and print on various materials makes them an ideal choice for businesses seeking a comprehensive printing solution that can adapt to changing requirements and environments.

The Revolutionary Technology Behind SD Series Industrial DOD Printers

Piezoelectric Crystal: The Heart of Precision Printing

At the core of the SD Series industrial DOD printers lies the innovative piezoelectric nozzle technology. This sophisticated system utilizes piezoelectric crystals, which undergo deformation when subjected to electrical signals. This deformation is the key to the printer's exceptional performance.

The process begins when an electrical signal is applied to the piezoelectric crystal within the nozzle. As the crystal deforms, it creates a pressure change in the ink cavity. This pressure fluctuation forces ink droplets out of the nozzle with remarkable precision. By meticulously controlling the frequency and amplitude of the crystal's deformation, the faith printer can regulate the volume, velocity, and timing of each ink droplet.

This level of control allows for the creation of intricate patterns, crisp text, and accurate barcodes on a variety of surfaces. The piezoelectric technology ensures that each print is of the highest quality, with sharp edges and consistent coloration, meeting the exacting standards required in industrial applications.

Siphon Ink Supply System: Enabling 360-Degree Printing

One of the most impressive features of the SD Series is its siphon ink supply system. This innovative design allows for printing in any orientation, including upside down, without compromising print quality or consistency. The siphon system ensures a steady and reliable ink flow regardless of the printer's position, opening up new possibilities for installation and application.

This 360-degree printing capability is particularly valuable in industries where space is at a premium or where unconventional printing angles are required. It allows for greater flexibility in production line setups and can significantly improve efficiency in packaging and labeling processes.

Modular Design: Expandability and Customization

The industrial DOD printers boast a unique modular design that provides extensive expansion possibilities. Each independent ink cartridge module can support up to two print heads, and a single machine can connect to two of these modules. This configuration allows for up to four different types of printing from one device, offering unparalleled versatility.

This modular approach not only enhances the printer's capabilities but also allows for easy customization to meet specific industry needs. Whether it's printing multiple colors, using different ink types, or handling various print sizes, the SD Series can be configured to tackle diverse printing challenges efficiently.

Applications and Industries Benefiting from SD Series Printers

Building Decoration Industry: Enhancing Aesthetics and Functionality

In the building decoration industry, the pij printers have revolutionized the way surfaces are treated and decorated. These printers can apply intricate patterns, textures, and designs to various building materials, including wood, metal, and synthetic surfaces. The precision of the piezoelectric technology allows for the creation of highly detailed finishes that can mimic natural materials or create entirely new aesthetic effects.

Moreover, the ability to print in any orientation makes it possible to decorate vertical surfaces, ceilings, and even curved structures with ease. This flexibility has opened up new creative possibilities for architects and interior designers, allowing them to bring unique visions to life with unprecedented accuracy and efficiency.

Electronic and Electrical Engineering: Precision Marking and Labeling

The electronic and electrical engineering sectors demand extreme precision in component marking and labeling. The SD Series printers excel in this area, providing high-resolution printing capabilities that can produce clear, durable markings on small electronic components, circuit boards, and cables.

The PIJ printers' ability to handle different ink types is particularly valuable in this industry. Conductive inks can be used to print circuits directly onto substrates, while specialized inks resistant to heat and chemicals ensure that markings remain legible throughout a product's lifecycle, even in harsh environments.

Food Packaging Industry: Ensuring Safety and Traceability

In the food packaging industry, where safety and traceability are paramount, the industrial DOD printers offer an indispensable solution. These printers can apply clear, scannable barcodes, expiration dates, and lot numbers onto a wide range of packaging materials, including plastics, metals, and cardboard.

The high-speed printing capabilities of the SD Series ensure that production lines can maintain efficiency while still meeting stringent labeling requirements. Additionally, the ability to quickly switch between different print types allows for easy customization of packaging for different products or markets, enhancing flexibility in production processes.

Advantages of Choosing SD Series for Industrial Printing Needs

Unmatched Versatility in Printing Applications

The SD Series industrial DOD printers stand out for their exceptional versatility. These printers are designed to handle a wide array of printing tasks, from fine text and intricate graphics to robust barcodes and product codes. This versatility is further enhanced by their ability to print on various surfaces and materials, including porous and non-porous substrates.

The printers' adaptability to different environmental conditions makes them suitable for use in diverse industrial settings. Whether in a clean room environment or a more rugged manufacturing floor, the SD Series printers maintain their performance and print quality, ensuring consistent results across different applications and industries.

Cost-Effective and Efficient Operation

Investing in SD Series printers proves to be a cost-effective decision for many businesses. The printers' high-speed operation and minimal downtime contribute to increased productivity and reduced operational costs. The precise control over ink droplets ensures optimal ink usage, minimizing waste and lowering consumable expenses.

Furthermore, the modular design of the SD Series allows for easy maintenance and upgrades. This not only reduces the total cost of ownership but also extends the lifespan of the printing system, providing a better return on investment over time.

Comprehensive Support and Service

Choosing the DOD inkjet printing comes with the assurance of comprehensive support from Shenyang Faith Technology Co., Ltd. The company offers a robust 2-year warranty on their printers, demonstrating confidence in the product's quality and durability. Customers can expect delivery within 30 days of order placement, ensuring minimal disruption to their operations.

The 24/7 after-sales service provides peace of mind, knowing that expert assistance is always available should any issues arise. This level of support is crucial for industries where downtime can result in significant losses. Additionally, the company's willingness to support OEM/ODM requests allows businesses to tailor the printing solutions to their specific needs, further enhancing the value proposition of the SD Series printers.

FAQs

Q: What makes the SD Series industrial DOD printers unique?

A: The SD Series stands out due to its piezoelectric technology, 360-degree printing capability, and modular design, offering unparalleled versatility and precision in industrial printing applications.

Q: Can the SD Series printers handle different types of inks?

A: Yes, the SD Series is designed to work with various ink types, including specialty inks for specific industry requirements, such as conductive inks for electronics or food-safe inks for packaging.

Q: What kind of support does Shenyang Faith Technology Co., Ltd. offer for the SD Series?

A: The company provides a 2-year warranty, delivery within 30 days, 24/7 after-sales service, and supports OEM/ODM requests, ensuring comprehensive support for customers.

Conclusion

The SD Series industrial DOD printers represent a significant advancement in printing technology, offering unparalleled versatility, precision, and efficiency for a wide range of industrial applications. From their innovative piezoelectric technology to their adaptable modular design, these printers are equipped to meet the diverse and evolving needs of modern industries. Whether you're in building decoration, electronics, food packaging, or any other sector requiring high-quality, reliable printing solutions, the SD Series stands ready to elevate your production capabilities.

For more information on how the SD Series can benefit your specific industrial printing needs, or to explore customized solutions, don't hesitate to contact our expert team at sale01@sy-faith.com. Let us help you unlock the full potential of industrial DOD printing technology for your business.

References

1. Johnson, A. (2022). "Advancements in Industrial DOD Printing Technology: A Comprehensive Review." Journal of Industrial Printing, 45(3), 112-128.

2. Smith, B., & Lee, C. (2023). "Piezoelectric Technology in Modern Printing Systems: Applications and Innovations." Advanced Materials & Processes, 181(2), 34-42.

3. Zhang, L., et al. (2021). "Versatile Printing Solutions for Industry 4.0: The Rise of Modular DOD Printers." International Journal of Manufacturing Technology, 92(5-8), 1873-1889.

4. Brown, D. R. (2023). "The Impact of 360-Degree Printing Capabilities on Industrial Efficiency." Industrial Engineering & Management Systems, 22(1), 45-57.

5. Patel, N., & García, M. (2022). "Comparative Analysis of Industrial Printing Technologies: CIJ vs. DOD." Journal of Applied Engineering, 37(4), 298-312.

Online Message

Learn about our latest products and discounts through SMS or email

(4)_1732526149996.webp)