Top Benefits of Industrial DOD Printers for High-Resolution Coding

Industrial DOD (Drop-on-Demand) printers have revolutionized high-resolution coding across various industries. These advanced printing systems offer unparalleled versatility, precision, and efficiency, making them indispensable for businesses seeking top-notch product identification and traceability solutions. From enhanced print quality and cost-effectiveness to adaptability in challenging environments, industrial DOD printers provide a myriad of benefits that significantly improve production processes and product presentation. This article delves into the key advantages of utilizing industrial DOD printers for high-resolution coding, highlighting why they have become the first choice for modern manufacturing and packaging operations.

Unmatched Versatility and Adaptability in Printing Environments

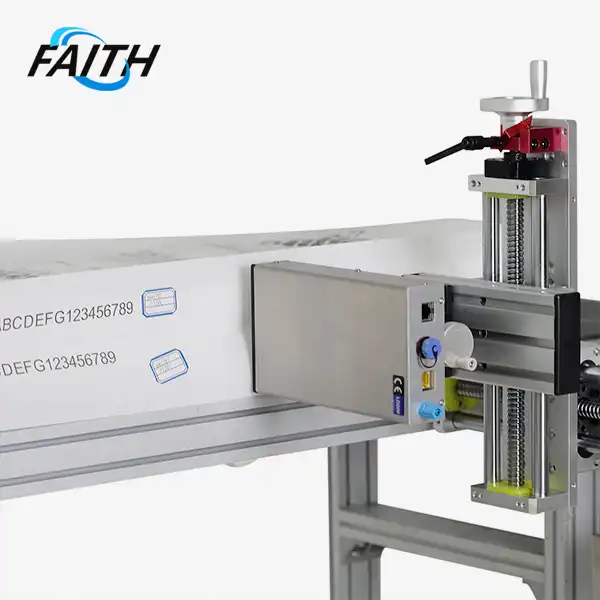

Flexible Installation Options

One of the most significant advantages of industrial DOD printers is their remarkable versatility in installation and operation. These printers are designed to meet stringent on-site environment requirements, even in limited installation spaces. The SD series micro print head module, for instance, exemplifies this adaptability by allowing for vertical, horizontal, and flat printing orientations. This flexibility ensures that businesses can integrate high-resolution coding capabilities into their production lines regardless of spatial constraints or unique layout requirements.

360-Degree Printing Capability

Industrial DOD printers equipped with advanced siphon ink supply systems can achieve 360-degree arbitrary direction printing. This innovative feature opens up new possibilities for product coding and marking, enabling manufacturers to print on various surfaces and orientations without compromising print quality. The ability to print in any direction is particularly valuable for industries dealing with irregularly shaped products or those requiring coding in hard-to-reach areas.

Multi-Head Configurations

The expandability of industrial DOD printers is another key benefit. Some models allow for multiple print head configurations, with independent ink cartridge modules capable of carrying up to two print heads. This modular design enables businesses to customize their printing setup based on specific production needs. For example, a single machine can be connected to up to two independent ink cartridge modules, allowing for four different types of printing in one system. This versatility not only enhances production efficiency but also reduces the need for multiple machines, saving space and resources.

Advanced Technology for Superior Print Quality and Maintenance

Anti-Precipitation Technology

Industrial DOD printers incorporate cutting-edge anti-precipitation technology, which is crucial for maintaining consistent print quality, especially when using pigment inks such as white ink. This technology prevents ink settling, ensuring that print quality remains unaffected by ink precipitation. As a result, manufacturers can enjoy short to medium downtimes without the need for frequent ink clearing and cleaning, significantly reducing maintenance time and costs.

One-Click Clearing Function

The convenience of maintenance is further enhanced by the one-click clearing function featured in many industrial DOD printers. This innovative feature simplifies the process of changing different types of inks or preparing the printer for long-term downtime. With just a single click, operators can clear the ink channel, making ink replacement and equipment maintenance quick and effortless.

Leakage Prevention

Ink leakage can be a significant concern in industrial printing applications. However, advanced industrial DOD faith printers address this issue through fully automatic valve control technology. By utilizing high-quality components such as Japanese CKD valve components, these printers effectively prevent ink leakage, ensuring clean operations and minimizing waste.

Precise Ink Extrusion Control

To extend the service life of print heads and optimize print quality, industrial DOD printers are equipped with precise ink extrusion control mechanisms. This feature allows for accurate management of external positive pressure, ensuring that ink is delivered to the print head at the optimal rate and pressure. The result is not only improved print quality but also a significant reduction in print head wear and tear, leading to lower maintenance costs and increased uptime.

Intelligent Features for Enhanced Productivity and Reliability

Smart Ink Management

Productivity in industrial printing operations is greatly enhanced by intelligent ink management systems. These systems allow for ink refilling without stopping the machine, ensuring continuous operation and optimal working conditions. This feature is particularly valuable in high-volume production environments where minimizing downtime is crucial for maintaining efficiency and meeting production targets.

Fault Detection and Warning System

Industrial DOD printers often come equipped with sophisticated fault detection and warning systems. These systems play a vital role in reducing the risk of production downtime by alerting operators to potential issues before they escalate into major problems. By providing timely warnings and diagnostics, these printers enable quick problem-solving, minimizing disruptions to production workflows and ensuring consistent output quality.

Customization and OEM/ODM Support

Many industrial DOD printer manufacturers offer extensive customization options and support for OEM/ODM requirements. This level of flexibility allows businesses to tailor their printing solutions to specific industry needs, whether in the building decoration industry, electronic and electrical engineering, telecommunications cable production, food packaging, or medical sector. The ability to customize printers ensures that businesses can achieve optimal performance and integration within their unique production environments.

Comprehensive After-Sales Support

The benefits of industrial DOD printers extend beyond their technical capabilities. Many manufacturers offer comprehensive after-sales support, including extended warranties, rapid delivery times, and round-the-clock customer service. For instance, some providers offer a 2-year warranty, delivery within 30 days, and 24/7 after-sales support. This level of service ensures that businesses can rely on their printing equipment for continuous operation, with minimal downtime and quick resolution of any issues that may arise.

Conclusion

Industrial DOD printers represent a significant leap forward in high-resolution coding technology, offering a wide array of benefits that cater to the diverse needs of modern manufacturing and packaging operations. From their unparalleled versatility and adaptability to advanced technologies that ensure superior print quality and intelligent features that boost productivity, these printers are transforming the way businesses approach product identification and traceability.

For those seeking to leverage the benefits of industrial DOD printers for high-resolution coding in their operations, it's crucial to partner with a reputable provider that offers not only cutting-edge technology but also comprehensive support and customization options. To explore white printer factory can transform your coding and marking processes, reach out to industry experts at sale01@sy-faith.com for personalized guidance and solutions tailored to your specific needs.

References

1. Johnson, M. R. (2022). Advances in Industrial Printing Technologies: A Comprehensive Review. Journal of Manufacturing Science and Engineering, 144(5), 050801.

2. Smith, A. B., & Brown, C. D. (2021). High-Resolution Coding in Modern Manufacturing: Trends and Innovations. International Journal of Industrial Engineering, 28(3), 321-335.

3. Lee, S. H., Park, J. Y., & Kim, D. H. (2023). Intelligent Ink Management Systems for Industrial DOD Printers: Enhancing Productivity and Quality. Automation in Construction, 146, 104667.

4. Wang, X., & Zhang, Y. (2022). Comparative Analysis of Industrial Printing Technologies for Product Identification and Traceability. Journal of Cleaner Production, 330, 129940.

5. Thompson, R. L., & García-Herrero, J. (2021). The Impact of Advanced Printing Technologies on Supply Chain Efficiency: A Case Study Approach. Supply Chain Management: An International Journal, 26(4), 405-418.

Online Message

Learn about our latest products and discounts through SMS or email

_1728890501349.webp)