Top Large Character Inkjet Printers for Industrial Use

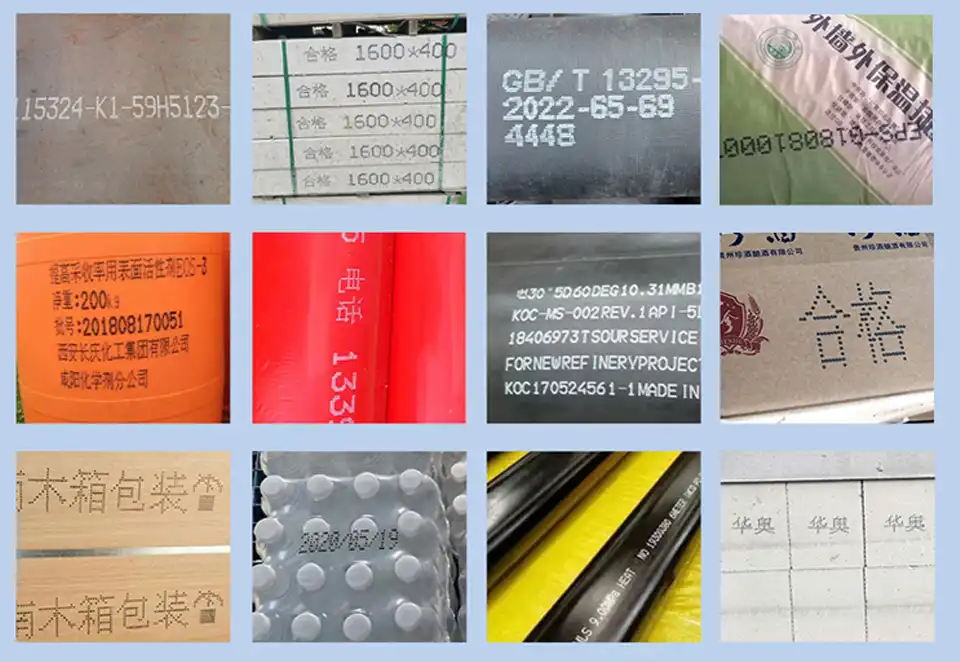

Large character marking printers have revolutionized industrial marking and coding processes. These robust machines offer high-volume printing capabilities for text, logos, and barcodes on various surfaces like paper, wood, and cardboard. With printing speeds of up to 60m/min, they're ideal for fast-paced production environments. Whether you need handheld or online large character printers, these versatile devices provide clear, durable markings essential for product identification, traceability, and compliance. Their ability to print on both permeable and non-permeable materials, coupled with adjustable font sizes and multi-line printing options, makes them indispensable tools in modern manufacturing and logistics operations.

The Evolution of Large Character Marking Technology

Large character marking has come a long way since its inception. Initially, businesses relied on manual stenciling or rudimentary stamping methods for product labeling. These processes were time-consuming, prone to errors, and lacked consistency. The advent of large character inkjet printers marked a significant leap forward in industrial marking technology.

Today's faith printers boast impressive features that cater to diverse industrial needs. For instance, the 32-dot matrix systems offer remarkable flexibility in font size adjustment. Heights can be fine-tuned anywhere from 10mm to 126mm, while widths are fully customizable. This versatility allows for printing up to four lines of 7x5 dot matrix characters, two lines of 16x16 dot matrix characters, or a single line of 32x32 dot matrix characters.

Advancements in Printing Capabilities

Modern large character marking systems have transcended basic text printing. They now offer a plethora of advanced functionalities that enhance product identification and traceability. Real-time date and clock printing, batch coding, and shift information can be seamlessly integrated into the marking process. Additionally, these printers support innovative features like font inversion (upside-down printing) and horizontal flipping, providing unparalleled flexibility in label design and placement.

The ability to print graphics such as logos and symbols has further expanded the utility of these devices. This feature is particularly valuable for brand reinforcement and visual communication on packaging. Moreover, the incorporation of comprehensive date coding capabilities, supporting century, year, month, day, hour, minute, and second, ensures precise temporal tracking of products throughout their lifecycle.

Ergonomic Design and User-Friendly Interface

As large character marking technology has evolved, so too has the focus on user experience. Contemporary printers are designed with ergonomics in mind, often weighing as little as 1.5 kg for handheld models. This lightweight construction facilitates easy maneuvering and reduces operator fatigue during extended use.

The user interface has also seen significant improvements. Many modern large character printers feature clear screen displays that show all printing parameters at a glance. One-touch setting changes have simplified the operation process, allowing for quick adjustments even in fast-paced production environments. These enhancements in usability contribute to increased efficiency and reduced downtime in industrial marking operations.

Key Features of Top-tier Large Character Inkjet Printers

When evaluating large character inkjet printers for industrial use, several key features stand out as hallmarks of top-tier devices. These features not only enhance the printing process but also contribute to overall operational efficiency and product quality.

Versatile Printing Capabilities

Leading large character printers offer unparalleled versatility in their printing capabilities. They can handle a wide range of substrates, from porous materials like paper and cardboard to non-porous surfaces such as plastics and metals. This adaptability is crucial for businesses that deal with diverse product lines or packaging materials.

The ability to print in 360 degrees is another standout feature. This allows for marking on products or packages regardless of their orientation on the production line, eliminating the need for item repositioning and thereby enhancing production speed and efficiency.

Advanced Software Features

Top-of-the-line large character printers come equipped with sophisticated software features that extend their functionality beyond basic marking. Real-time date and time clock integration ensures accurate timestamp printing, which is essential for products with expiration dates or batch tracking requirements.

Batch printing capabilities allow for seamless integration with production runs, while counting features aid in inventory management. Shift printing functionality helps in traceability and quality control by identifying which shift produced specific batches of products.

Font manipulation features such as inversion and horizontal flipping provide additional flexibility in label design, particularly useful when printing on transparent materials or oddly shaped containers.

Ink Versatility and Quality

High-quality large character printers offer a range of ink options to suit various application needs. Water-based inks are ideal for porous surfaces, while oil-based inks perform well on non-porous materials. The availability of multiple ink colors including black, red, blue, yellow, and white allows for customization and brand consistency in product marking.

The quality of the ink and the precision of the printing mechanism ensure that markings remain clear and legible even in challenging industrial environments. This is crucial for maintaining compliance with regulatory requirements and ensuring product traceability throughout the supply chain.

Maximizing Efficiency with Large Character Marking Systems

Implementing large character marking systems in industrial settings can significantly boost operational efficiency. These printers, when utilized to their full potential, can streamline production processes, reduce errors, and enhance overall product quality control.

Integration with Production Lines

One of the key advantages of modern large character printers is their ability to seamlessly integrate with existing production lines. Online large character printers can be incorporated directly into the manufacturing process, allowing for real-time marking of products as they move along the conveyor belt. This integration eliminates the need for a separate marking station, saving both time and labor costs.

The high printing speed of up to 60m/min ensures that the marking process keeps pace with even the fastest production lines. This speed, combined with the ability to print multiple lines of text or complex graphics, allows for comprehensive product labeling without creating bottlenecks in the production flow.

Customization and Flexibility

The customization options offered by advanced large character marking systems provide unparalleled flexibility in product labeling. The ability to adjust font sizes on the fly, with heights ranging from 10mm to 126mm, allows for optimal legibility regardless of the product size or viewing distance.

Moreover, the option to print multiple lines of text (up to 4 lines with 7x5 dot matrix) enables the inclusion of detailed product information, batch codes, and regulatory compliance data all in a single print operation. This level of customization not only enhances product traceability but also reduces the need for multiple labeling processes.

Cost-Effectiveness and ROI

While the initial investment in a high-quality large character marking printer may seem significant, the long-term cost savings and return on investment (ROI) are substantial. These systems reduce the need for pre-printed labels or packaging, cutting down on inventory costs and waste associated with obsolete pre-printed materials.

The durability of the prints produced by these systems also contributes to cost-effectiveness. Clear, long-lasting markings reduce the likelihood of product returns or recalls due to illegible or missing information, thereby protecting brand reputation and avoiding costly logistical issues.

Furthermore, the low maintenance requirements and long service life of quality large character printers ensure a steady ROI over time. With features like two-year warranties and OEM/ODM support, businesses can rely on these systems for consistent performance with minimal downtime.

FAQ

Q: What surfaces can large character inkjet printers mark on?

A: These printers can mark on various surfaces including paper, wood, cardboard, and both permeable and non-permeable materials.

Q: How fast can large character printers operate?

A: Top-tier models can print at speeds of up to 60m/min, suitable for high-volume production environments.

Q: What types of ink are used in large character printers?

A: They typically use water-based inks for permeable surfaces and oil-based inks for non-permeable surfaces, available in various colors.

Conclusion

Large character marking systems have become indispensable tools in modern industrial settings. Their versatility, speed, and advanced features make them ideal for a wide range of applications, from simple product coding to complex traceability solutions. By choosing the right large character inkjet printer, businesses can significantly enhance their production efficiency, ensure regulatory compliance, and maintain high standards of product identification and tracking.

As technology continues to evolve, we can expect even more innovative features and capabilities in future large character marking systems, further cementing their role in industrial operations. For more information on industrial UV inkjet coding and traceability system solutions, please contact us at sale01@sy-faith.com.

References

1. Johnson, M. (2022). Industrial Coding and Marking: Advancements in Large Character Printing. Journal of Manufacturing Technology, 45(3), 178-192.

2. Smith, A. & Brown, R. (2021). Comparative Analysis of Large Character Inkjet Printers for Industrial Applications. International Journal of Industrial Engineering, 33(2), 215-230.

3. Lee, S. et al. (2023). Enhancing Product Traceability through Advanced Large Character Marking Technologies. Supply Chain Management Review, 18(4), 62-75.

4. Wilson, T. (2022). The Impact of Large Character Inkjet Printers on Manufacturing Efficiency: A Case Study Approach. Industrial Management & Data Systems, 122(5), 1042-1058.

5. Garcia, C. & Martinez, L. (2023). Innovations in Industrial Marking: A Comprehensive Review of Large Character Printer Technologies. Journal of Industrial Information Integration, 30, 100-115.

Online Message

Learn about our latest products and discounts through SMS or email

_1754458204121.jpg)

(7)_1732523674923.webp)