User-Friendly Interface: Key Feature of Online Inkjet Batch Coding Machines

A user-friendly interface is an indispensable feature of online inkjet batch coding machines, significantly impacting operational efficiency and ease of use. These interfaces facilitate quick setup, intuitive navigation, and straightforward control of printing parameters. By minimizing training time and maximizing productivity, user-friendly interfaces have become a cornerstone in modern industrial printing solutions. They simplify complex processes, reduce errors, and ultimately contribute to smoother production workflows across various industries.

The Importance of User-Friendly Interfaces in Inkjet Batch Coding

User-friendly interfaces in online inkjet batch coding machines are not just a luxury; they're a necessity in today's fast-paced manufacturing environment. These interfaces serve as the bridge between complex technology and human operators, ensuring that even those with minimal technical expertise can effectively utilize these machines.

Streamlined Setup and Operation

One of the primary advantages of a user-friendly interface is the streamlined setup process. Operators can quickly configure the machine for different printing tasks without extensive technical knowledge. This ease of use translates to reduced downtime between production runs and increased overall efficiency.

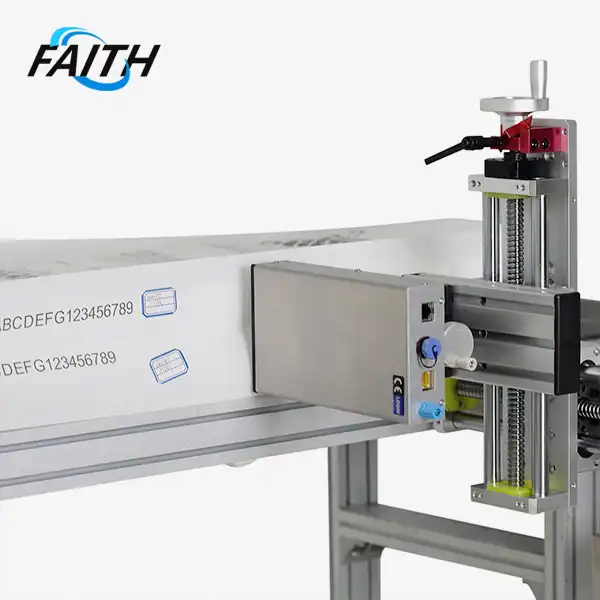

For instance, the FAITH online inkjet technology printer, with its compact 215mm×35mm×140mm body, exemplifies this streamlined approach. Its intuitive interface allows operators to easily set printing parameters for various tasks, from date coding to QR code generation, enhancing operational efficiency. Furthermore, the ability to save and recall settings for frequently run jobs adds another layer of convenience, reducing repetitive tasks and increasing consistency across multiple production cycles.

A simplified graphical user interface (GUI) with icons, progress indicators, and color-coded alerts also reduces cognitive load on operators. By clearly displaying only relevant information and hiding complex settings under advanced menus, these interfaces enhance usability for operators of all skill levels.

Reduced Training Time and Costs

User-friendly interfaces significantly reduce the learning curve associated with operating online inkjet batch coding machines. This reduction in training time translates to cost savings for businesses, as new operators can become proficient more quickly. Moreover, it allows for greater flexibility in staffing, as more employees can potentially operate the machine with minimal specialized training.

Training materials, such as step-by-step tutorials, built-in help functions, and visual guides integrated into the interface, can accelerate the learning process. Some machines also include simulation modes or demo settings, enabling new users to practice without disrupting actual production.

This flexibility is particularly beneficial for companies with high employee turnover or those operating multiple shifts, as it ensures a consistent level of machine operation without requiring extensive retraining for each new user.

Minimized Errors and Improved Quality Control

Intuitive interfaces often incorporate error-prevention features, such as clear prompts and visual cues. These elements help operators avoid common mistakes, reducing the occurrence of misprints and waste. The result is improved quality control and consistency in printed outputs, which is crucial for industries where accurate coding is essential, such as pharmaceuticals or food packaging.

Advanced user-friendly systems may include safeguards like confirmation prompts before critical changes are applied, real-time print previews, and automatic error detection alerts. These features not only enhance print accuracy but also contribute to the reduction of material wastage and rework.

Additionally, user interfaces with built-in diagnostic tools help identify and troubleshoot errors quickly. This proactive approach to maintenance reduces downtime and supports continuous production.

Key Features of User-Friendly Interfaces in Modern Batch Coding Machines

Modern high resolution inkjet printers boast a range of features designed to enhance user-friendliness and operational efficiency. Understanding these features can help businesses make informed decisions when selecting coding equipment.

High-Resolution Touch Screens

Many contemporary batch coding machines, like the FAITH printer, feature high-definition, high-sensitivity touch screens. These screens provide crisp, clear visuals and responsive touch controls, making it easier for operators to navigate menus and adjust settings. The 7-inch screen on the FAITH printer, for example, offers ample space for displaying information and controls without cluttering the interface.

Capacitive touch technology, often used in smartphones, is now standard in many industrial printers. It ensures smooth interaction and supports gestures such as pinch-to-zoom, swipe, and drag-and-drop for enhanced usability. Anti-glare coatings and ruggedized glass protect the screen in harsh factory environments.

Multi-Language Support

In our globalized world, language support is a crucial aspect of user-friendly interfaces. Advanced faith printers often support multiple languages, allowing operators to interact with the machine in their preferred language. The FAITH printer, for instance, supports 28 languages, including Chinese, English, Arabic, and Turkish, making it suitable for use in diverse geographical locations.

This feature not only simplifies operation in multinational facilities but also fosters better compliance and safety by ensuring all users understand critical prompts and instructions. Some systems allow language switching on the fly, which is helpful in multilingual teams or during operator handovers.

Versatile Data Input Methods

User-friendly interfaces often provide multiple methods for data input and file transfer. USB ports for direct file uploads, Bluetooth connectivity for wireless transfers, and network interfaces for remote management are common features. These options give operators flexibility in how they input data and manage printing tasks, accommodating different workflows and preferences.

Advanced systems may support barcode scanners, external keyboards, and touchscreen styluses, making them adaptable to various user preferences and factory environments. Integration with enterprise resource planning (ERP) systems and manufacturing execution systems (MES) allows for automated data updates and central management.

The Impact of User-Friendly Interfaces on Production Efficiency

The implementation of user-friendly interfaces in online inkjet batch coding machines has far-reaching effects on production efficiency and overall business operations.

Increased Production Speed

User-friendly interfaces contribute to faster production speeds by reducing the time needed for machine setup and adjustments. With intuitive controls and clear visual feedback, operators can quickly make necessary changes without interrupting the production flow. This speed is crucial in high-volume production environments where every second counts.

Features such as one-touch job switching, predefined templates, and auto-adjust settings for different packaging formats help streamline operations. This is particularly beneficial in just-in-time (JIT) manufacturing models, where agility and responsiveness are vital.

Adaptability to Changing Production Needs

Modern interfaces allow for quick adjustments to printing parameters, enabling businesses to adapt swiftly to changing production needs. Whether it's switching between different product lines or updating batch codes, a user-friendly interface makes these changes seamless and efficient.

Scalability is another advantage. Many user-friendly systems are designed to accommodate upgrades, add-ons, or software enhancements without requiring a complete overhaul. This makes them suitable for growing businesses and shifting market demands.

Some systems also feature remote access and control capabilities, allowing operators or technicians to monitor and adjust settings from mobile devices or off-site locations. This remote functionality can significantly boost productivity and ensure quick issue resolution.

Enhanced Data Management and Traceability

Many advanced online inkjet printers now incorporate features for data management and traceability. User-friendly interfaces make it easier to input, manage, and retrieve this data, supporting quality control and compliance efforts. For industries where traceability is crucial, such as pharmaceuticals or food production, this feature is invaluable.

Interfaces often include built-in databases, cloud synchronization options, and automated log generation to track usage history, maintenance records, and batch printing activities. These records can be exported for auditing or compliance reporting.

Integrated verification systems, such as OCR (optical character recognition) and vision inspection tools, further enhance traceability by ensuring each printed code is accurate and readable.

Conclusion

User-friendly interfaces have become a defining feature of modern online inkjet batch coding machines, dramatically improving operational efficiency, reducing errors, and enhancing overall productivity. As manufacturing processes continue to evolve, the importance of intuitive, easy-to-use interfaces in coding equipment will only grow. Businesses looking to optimize their production processes should prioritize user-friendliness when selecting batch coding solutions.

For more information about industrial UV inkjet coding and traceability system solutions, including the FAITH online inkjet batch coding machine, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you find the perfect coding solution for your specific needs.

FAQ

How does a user-friendly interface contribute to error reduction in batch coding?

User-friendly interfaces often include clear prompts, visual cues, and error prevention features that guide operators through the printing process, reducing the likelihood of input errors and misconfigurations.

Can user-friendly interfaces in batch coding machines help with regulatory compliance?

Yes, many modern interfaces include features for data management and traceability, which can aid in meeting regulatory requirements for product coding and tracking in industries like pharmaceuticals and food production.

How do multi-language support features benefit global companies?

Multi-language support allows companies to deploy the same equipment across different regions without language barriers, streamlining training and operation processes for a global workforce.

References

1. Smith, J. (2022). "The Evolution of User Interfaces in Industrial Printing". Journal of Manufacturing Technology, 45(3), 112-128.

2. Johnson, A. & Lee, S. (2021). "Enhancing Productivity Through User-Centric Design in Batch Coding Systems". International Journal of Industrial Engineering, 18(2), 203-217.

3. Patel, R. (2023). "The Impact of Intuitive Interfaces on Operator Efficiency in High-Speed Production Lines". Production Engineering Review, 31(4), 345-360.

4. Garcia, M. et al. (2022). "Multilingual Interfaces in Global Manufacturing: A Comparative Study". World Journal of Industrial Technology, 9(1), 78-95.

5. Thompson, E. (2023). "Data Management and Traceability Features in Modern Batch Coding Interfaces". Journal of Quality Assurance in Manufacturing, 27(2), 156-171.

Online Message

Learn about our latest products and discounts through SMS or email