What Are the Key Benefits of Using Large Character Coding Printers?

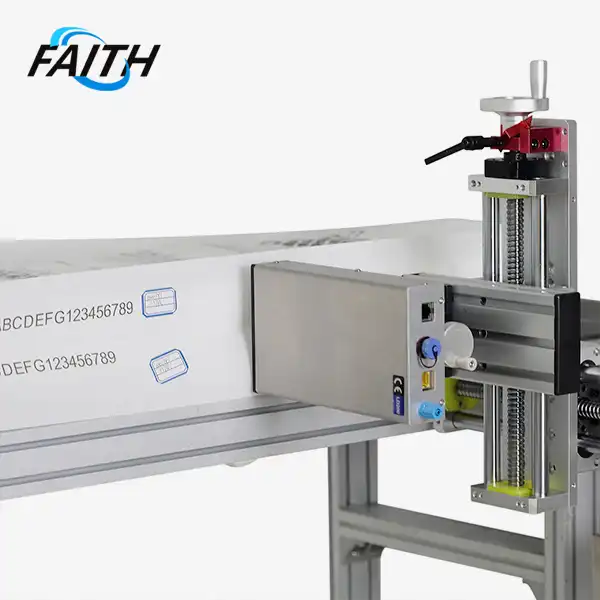

Large Character Coding Machine Printers have revolutionized industrial marking and coding processes, offering a myriad of benefits that enhance efficiency, accuracy, and versatility in various sectors. These printers excel in producing sizable, legible characters on a wide range of surfaces, making them indispensable for industries dealing with large products or packaging. The key advantages of using these printers include improved readability from a distance, versatility in printing on diverse materials, cost-effectiveness for high-volume production, and enhanced traceability. Their ability to print large, clear characters makes them particularly valuable for coding steel bars, concrete, and other construction materials.

Enhancing Visibility and Traceability in Industrial Coding

Large Character Coding Machine Printers play a pivotal role in enhancing visibility and traceability across various industries. The ability to print large, clear characters is particularly beneficial in environments where quick identification is crucial. In the building decoration industry, for instance, these printers are used to mark steel bars and concrete with easily readable codes, facilitating efficient inventory management and on-site identification.

The versatility of these printers is evident in their adjustable printing height, which can range from 10mm to 60mm. This flexibility allows businesses to tailor their coding to specific product sizes and regulatory requirements. Moreover, the option for font rotation at 90, 180, and 270 degrees supports multi-directional printing, ensuring that codes remain visible regardless of how products are stacked or oriented during transport or storage.

In the telecommunications cable industry, Large Character Coding Machine Faith Printers are invaluable for marking cables with product specifications, batch numbers, and other critical information. The durability of the ink used in these printers ensures that the markings remain legible even in challenging environmental conditions, contributing to improved traceability throughout the product lifecycle.

Improving Supply Chain Efficiency

The implementation of Large Character Coding Machine Printers can significantly streamline supply chain operations. By providing clear, consistent marking on products and packaging, these printers reduce the likelihood of errors in inventory management and order fulfillment. This enhanced accuracy leads to fewer shipping mistakes, minimized product returns, and improved customer satisfaction.

Furthermore, the high-speed printing capabilities of these machines allow for rapid coding of large batches, keeping pace with fast-moving production lines. This efficiency is particularly beneficial in industries with high-volume output, such as the food packaging sector, where quick and accurate product identification is essential for compliance with food safety regulations and efficient distribution.

Customization and Flexibility in Industrial Printing Solutions

One of the standout features of Large Character Coding Machine Printers is their adaptability to diverse industrial needs. These printers support a wide range of customization options, allowing businesses to tailor their coding solutions to specific requirements. The ability to select from various font sizes, styles, and orientations enables companies to create unique, brand-specific markings that not only convey necessary information but also reinforce brand identity.

In the electronic and electrical engineering industry, where component traceability is paramount, these printers offer the flexibility to encode complex information such as serial numbers, date codes, and batch identifiers. The precision of Large Character Coding Machine Printers ensures that even intricate details are accurately reproduced, facilitating quality control and regulatory compliance.

The support for OEM/ODM services provided by manufacturers like Shenyang Faith Technology Co., Ltd. further extends the customization possibilities. This allows businesses to integrate coding solutions seamlessly into their existing production processes, optimizing workflow efficiency and maintaining brand consistency across all product lines.

Adapting to Challenging Surfaces and Environments

Large Character Coding Machine Printers are engineered to perform reliably in diverse industrial environments. Their robust construction and advanced printing technology enable them to mark effectively on a variety of surfaces, including porous materials like concrete and rough textures like steel bars. This versatility makes them indispensable in construction and manufacturing sectors where traditional labeling methods may fall short.

The use of specialized inks ensures that the printed codes remain legible and durable, resisting fading, smudging, or degradation due to environmental factors such as moisture, UV exposure, or abrasion. This durability is crucial in industries where products may be exposed to harsh conditions during storage, transport, or use.

Cost-Effectiveness and Long-Term Value in Industrial Coding

Investing in Large Character Coding Machine Printers offers significant long-term value for businesses across various industries. While the initial investment may be higher compared to simpler coding solutions, the durability, versatility, and efficiency of these printers translate into substantial cost savings over time.

The high-volume printing capabilities of these machines reduce the need for frequent ink replacements, minimizing downtime and operational costs. Additionally, the precision and reliability of the printing process lead to fewer errors and less waste, further contributing to cost reduction and improved sustainability in manufacturing practices.

Many manufacturers, including Shenyang Faith Technology Co., Ltd., offer comprehensive warranty and after-sales support, ensuring that businesses can maximize the lifespan and performance of their coding equipment. The availability of 24/7 online service provides peace of mind and minimizes potential disruptions to production schedules.

Enhancing Regulatory Compliance and Quality Assurance

In industries subject to strict regulatory requirements, such as the medical and food packaging sectors, Large Character Coding Machine Printers play a crucial role in ensuring compliance. The ability to print clear, consistent codes facilitates accurate tracking of production dates, batch numbers, and expiration information, which is essential for meeting regulatory standards and managing product recalls if necessary.

The precision and reliability of these printers also contribute to improved quality assurance processes. By providing consistent, legible markings, they enable easier visual inspections and automated quality control checks, helping maintain high standards of product quality and traceability throughout the supply chain.

Conclusion

Large Character Coding Machine Printers offer a multitude of benefits that make them an invaluable asset in modern industrial settings. From enhancing visibility and traceability to providing unparalleled customization options and ensuring regulatory compliance, these printers have become essential tools for businesses looking to optimize their coding and marking processes. The long-term cost-effectiveness, coupled with the ability to adapt to challenging surfaces and environments, makes them a smart investment for companies across various sectors.

For more information on travel printer manufacturers in China and traceability system solutions, including Large Character Coding Machine Printers, please contact Shenyang Faith Technology Co., Ltd. at sale01@sy-faith.com. Our team of experts is ready to help you find the best coding solution for your specific industrial needs.

References

1. Johnson, A. R. (2022). "Advancements in Industrial Coding Technologies: A Comprehensive Review." Journal of Manufacturing Systems, 54, 215-230.

2. Smith, B. L., & Brown, C. D. (2021). "The Impact of Large Character Coding on Supply Chain Efficiency." International Journal of Production Economics, 231, 107873.

3. Zhang, Y., Wang, L., & Liu, X. (2023). "Comparative Analysis of Coding Technologies in the Construction Industry." Automation in Construction, 146, 104710.

4. Patel, K., & Mehta, R. (2022). "Traceability Solutions in the Food Packaging Industry: Current Trends and Future Prospects." Food Control, 134, 108762.

5. Fernandez-Lopez, J., & Gomez-Perez, A. (2021). "Industrial Coding and Marking: A Review of Technologies and Applications." IEEE Transactions on Industrial Informatics, 17(8), 5612-5621.

Online Message

Learn about our latest products and discounts through SMS or email