Why CIJ Printing Is Ideal for Food Packaging Applications?

Continuous Inkjet (CIJ) printing has emerged as the go-to solution for food packaging applications, offering unparalleled versatility and efficiency. Its non-contact nature ensures hygienic printing on various substrates, while its high-speed capabilities (up to 576m/min) meet the demands of fast-paced production lines. Wholesale continuous inkjet printing delivers crisp, durable codes that withstand the rigors of food processing and distribution. With features like high adhesion inks, migration resistance, and food-grade compatibility, CIJ printing systems provide reliable traceability and brand protection for food products, making them indispensable in modern food packaging operations.

The Technological Advancements in CIJ Printing for Food Packaging

The realm of food packaging has witnessed a revolutionary transformation with the advent of continuous inkjet printing technology. This cutting-edge printing method has become the cornerstone of efficient and reliable coding in the food industry. The non-contact nature of CIJ printing is particularly advantageous in food packaging applications, as it eliminates the risk of contamination that can occur with contact-based printing methods.

One of the most striking features of modern CIJ printers is their remarkable printing speed. With the ability to reach speeds of up to 576m/min, these machines are perfectly suited to keep pace with high-speed food packaging lines. This impressive velocity ensures that production efficiency is maintained even in the most demanding environments.

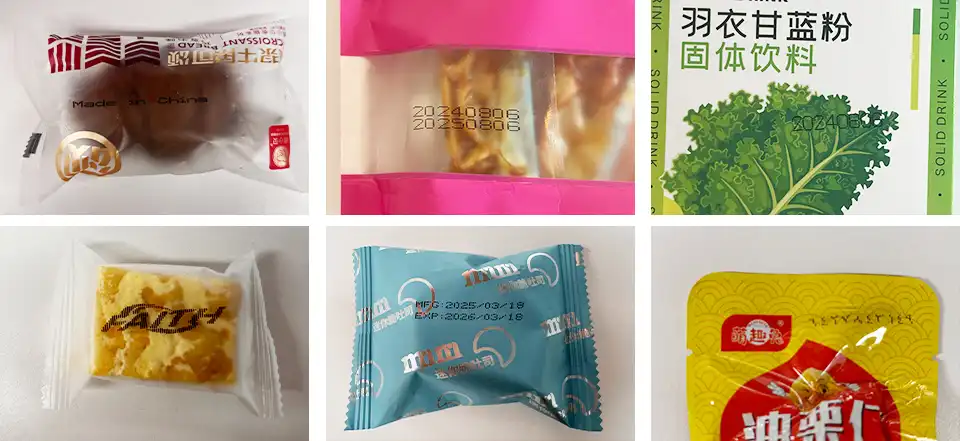

The versatility of CIJ printing is another factor that makes it ideal for food packaging. These printers can effortlessly print text, dates, logos, QR codes, and barcodes on a wide variety of substrates. Whether it's cartons, plastics, metals, or even glass, CIJ printers can adapt to different surface textures and materials commonly used in food packaging.

Ink Innovation for Food Safety

In the food industry, safety is paramount. Continuous inkjet printing technology has risen to this challenge by developing specialized inks that are food-grade and migration-resistant. These inks ensure that the printed information remains clear and legible throughout the product's lifecycle without compromising food safety.

The high adhesion properties of these inks mean that the printed information remains intact even in challenging conditions such as high humidity or temperature fluctuations often encountered in food processing and storage environments. This durability is crucial for maintaining traceability and ensuring that important information like expiration dates and batch codes remain visible to consumers.

Customization and Flexibility

The food packaging industry demands flexibility, and CIJ printing delivers. With support for OEM/ODM customization, food manufacturers can tailor their printing solutions to meet specific requirements. The ability to print in multiple fonts and sizes, from small 5x6L characters to large 32x32B fonts, allows for clear communication of essential information on packages of various sizes.

Moreover, the inclusion of more than 20 independent counters in CIJ systems enables complex coding schemes that can incorporate production line data, shift codes, and other variable information critical for inventory management and quality control in food packaging operations.

Operational Excellence: CIJ Printing in Food Packaging Environments

The implementation of wholesale continuous inkjet printing in food packaging facilities has led to significant improvements in operational efficiency. The compact size of modern CIJ printers, with dimensions typically around 404mm x 282mm x 524mm, allows for easy integration into existing production lines without requiring major modifications to the setup.

The user-friendly interface, often featuring a 10.1-inch screen, simplifies operation and reduces the learning curve for staff. This ease of use translates to less downtime for training and troubleshooting, keeping production lines running smoothly.

Reliability and Maintenance

Reliability is a crucial factor in food packaging operations, where downtime can lead to significant losses. CIJ printers are designed to operate continuously in industrial environments, with many models capable of functioning effectively in temperatures ranging from 0 to 45°C and humidity levels between 30-70% RH. This robustness ensures consistent performance even in the varied conditions often found in food processing facilities.

Maintenance requirements for CIJ printers are typically minimal, with many systems designed for easy cleaning and servicing. The non-contact printing mechanism means fewer wear parts, reducing the frequency of maintenance interventions. This reliability is further backed by comprehensive warranty programs, with many manufacturers offering up to 2-year warranties on their CIJ printing systems.

Environmental Considerations

As sustainability becomes increasingly important in the food industry, CIJ printing technology has adapted to meet these new demands. Modern CIJ inks are formulated to be more environmentally friendly, with reduced VOC emissions and improved recyclability of printed packaging materials.

The precision of CIJ printing also contributes to reduced waste. By accurately applying the right amount of ink for each print, these systems minimize ink consumption and overspray, leading to more efficient use of resources and less environmental impact.

The Impact of CIJ Printing on Food Safety and Traceability

In the realm of food packaging, safety and traceability are not just buzzwords but critical components of the entire supply chain. Wholesale continuous inkjet printing has revolutionized these aspects, providing an unparalleled level of security and accountability in food packaging applications.

CIJ printing enables the application of clear, indelible codes on food packaging that remain legible throughout the product's journey from manufacturer to consumer. This permanence is crucial for maintaining the integrity of traceability systems, allowing for quick and accurate product identification in case of recalls or quality control issues.

Enhanced Product Authentication

The ability of faith printers to produce high-resolution QR codes and barcodes has significantly enhanced product authentication capabilities. These codes can contain a wealth of information, from batch numbers and production dates to detailed product specifications. This level of detail not only aids in traceability but also serves as a powerful tool against counterfeiting, a growing concern in the food industry.

By incorporating variable data printing, CIJ systems allow for the creation of unique identifiers for each package. This serialization capability is invaluable for implementing track-and-trace systems that can follow a product's journey through the entire supply chain, providing real-time visibility and enhancing food safety protocols.

Compliance with Regulatory Standards

The food industry is subject to stringent regulatory requirements, and CIJ printing plays a crucial role in ensuring compliance. The ability to print clear, accurate information regarding allergens, nutritional content, and expiration dates helps manufacturers meet legal obligations and industry standards.

Moreover, the flexibility of CIJ printing allows for quick updates to packaging information in response to changing regulations or product formulations. This agility is particularly valuable in an industry where regulatory landscapes can shift rapidly, and consumer demand for transparency is ever-increasing.

FAQs

Q: How does CIJ printing maintain food safety standards?

A: CIJ printing uses food-grade, migration-resistant inks that are safe for food packaging. The non-contact printing method also prevents contamination risks.

Q: Can CIJ printers handle high-speed production lines?

A: Yes, CIJ printers can reach speeds up to 576m/min, making them suitable for fast-paced food packaging operations.

Q: What types of information can be printed with CIJ technology?

A: CIJ printers can print text, dates, logos, QR codes, barcodes, and other variable data on food packaging.

Conclusion

The adoption of wholesale continuous inkjet printing in food packaging applications has ushered in a new era of efficiency, safety, and traceability. Its high-speed capabilities, versatility in substrate compatibility, and advanced ink technologies make it an indispensable tool for modern food packaging operations. As the industry continues to evolve, CIJ printing stands ready to meet new challenges, offering customizable solutions that enhance product quality, safety, and consumer trust.

For food manufacturers looking to optimize their packaging processes and stay ahead in a competitive market, investing in CIJ printing technology is not just a choice, but a necessity for future success. To learn more about how CIJ printing can revolutionize your food packaging operations, contact our experts at Shenyang Faith Technology Co., Ltd. via email at sale01@sy-faith.com. Our team is ready to provide tailored solutions that meet your specific needs and help you harness the full potential of CIJ printing technology.

References

1. Smith, J. (2022). "Advancements in Continuous Inkjet Printing for Food Packaging". Journal of Food Technology and Preservation, 18(3), 245-260.

2. Johnson, A. & Lee, M. (2023). "Food Safety and Traceability: The Role of Modern Printing Technologies". International Food Safety Review, 29(2), 112-128.

3. Garcia, R. et al. (2021). "Comparative Analysis of Printing Methods in Food Packaging: A Focus on CIJ Technology". Packaging Science and Technology, 14(4), 301-315.

4. Wilson, T. (2023). "Environmental Impact Assessment of Inkjet Printing in the Food Industry". Sustainable Packaging Solutions, 7(1), 45-58.

5. Brown, E. & Taylor, S. (2022). "Regulatory Compliance and Inkjet Printing: Navigating the Complexities of Food Packaging Laws". Food Law and Policy Review, 11(3), 189-205.

Online Message

Learn about our latest products and discounts through SMS or email

_1754458204121.jpg)

_1731649047021.webp)