Why Continuous Small Character Ink Jet Printers Are Essential for Modern Production?

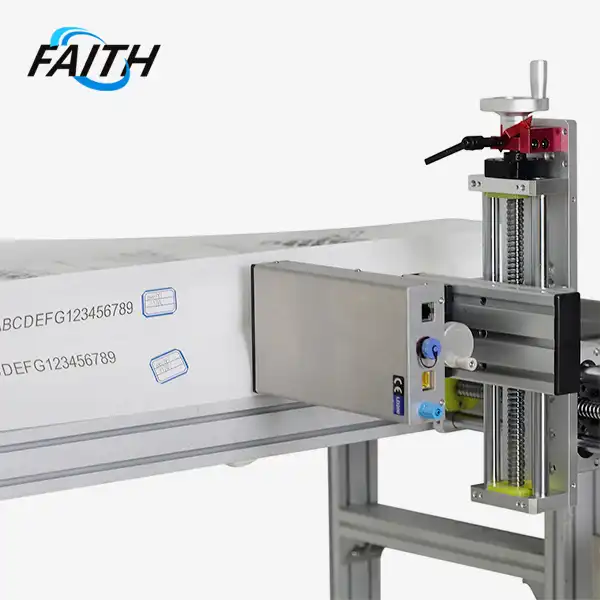

Continuous small character ink jet printers have become indispensable in modern production environments due to their versatility, speed, and precision. These advanced printing systems offer unparalleled flexibility in coding and marking across various industries, including food and beverage, pharmaceuticals, healthcare, beauty, cable and wire manufacturing, and industrial markets. With the ability to print at high speeds up to 576m/min and produce high-quality images using the finest ink droplets without direct contact, continuous inkjet technology has revolutionized product identification and traceability. The compact size, customizable features, and minimal ink consumption make these printers an essential tool for businesses seeking to optimize their production processes and meet stringent regulatory requirements.

The Evolution of Continuous Small Character Ink Jet Printing Technology

The journey of continuous small character ink jet printing technology has been marked by significant advancements over the years. From its humble beginnings to its current state-of-the-art capabilities, this technology has undergone a remarkable transformation.

Historical Perspective

The concept of continuous inkjet printing dates back to the 1960s when it was first developed for recording electronic signals. However, it wasn't until the 1970s that this technology found its way into industrial applications. Early continuous inkjet printers were bulky, had limited printing capabilities, and were primarily used for basic coding tasks.

As manufacturing processes became more sophisticated, the demand for more versatile and efficient coding solutions grew. This led to rapid advancements in continuous inkjet technology throughout the 1980s and 1990s. Manufacturers focused on improving print quality, increasing printing speeds, and expanding the range of substrates that could be marked.

Technological Breakthroughs

The turn of the millennium brought about significant technological breakthroughs in continuous small character ink jet printing. The introduction of micro-droplet technology allowed for even finer print resolution, enabling the production of crisp, clear codes on even the smallest of surfaces.

Another major advancement was the development of fast-drying inks that could adhere to a wide variety of materials, including plastics, metals, and glass. This expanded the application of continuous inkjet printers across various industries, from food packaging to automotive parts marking.

Integration of Digital Technology

The integration of digital technology has been a game-changer for continuous small character ink jet printers. Modern printers now come equipped with sophisticated software that allows for easy integration with production line systems, real-time monitoring, and remote diagnostics.

Touch screen interfaces, like the 10.1-inch screen found on many contemporary models, have simplified printer operation and maintenance. These user-friendly interfaces allow operators to quickly change print messages, adjust settings, and troubleshoot issues without extensive training.

Key Features and Benefits of Modern Continuous Small Character Ink Jet Printers

Contemporary continuous small character ink jet printers boast an impressive array of features that make them indispensable in modern production environments. Let's explore some of these key attributes and their benefits.

Unmatched Versatility

One of the most significant advantages of continuous small character ink jet printers is their remarkable versatility. These faith printers can effortlessly handle a wide range of printing tasks, from simple date codes to complex logos, QR codes, and barcodes. This versatility is particularly valuable in industries where product information changes frequently or where multiple product lines are run on the same production line.

High-Speed Performance

In today's fast-paced production environments, speed is of the essence. Modern continuous small character ink jet printers deliver on this front, with some models capable of printing at speeds up to 576m/min. This high-speed performance ensures that coding and marking processes do not become bottlenecks in production lines, even in high-volume manufacturing scenarios.

Precision and Quality

Despite their high-speed capabilities, continuous small character ink jet printers do not compromise on print quality. These printers produce high-quality images using the finest ink droplets, resulting in clear, legible codes even on small or challenging surfaces. The non-contact printing method also ensures that the integrity of the product packaging is maintained, which is particularly crucial in industries like food and pharmaceuticals.

Compact and Efficient Design

Modern continuous inkjet printers are designed with efficiency in mind. With compact dimensions (typically around 404mm x 282mm x 524mm), these printers can be easily integrated into existing production lines, even in spaces where real estate is at a premium. Their efficient design also extends to ink consumption, with many models offering minimal ink usage without sacrificing print quality.

Customization and Flexibility

The ability to customize printing solutions is another key feature of modern continuous small character ink jet printers. Many manufacturers, including Shenyang Faith Technology Co., Ltd., offer OEM/ODM support, allowing businesses to tailor their printing solutions to their specific needs. This flexibility ensures that businesses can optimize their coding and marking processes to align with their unique production requirements.

Applications Across Industries

The versatility and efficiency of continuous small character ink jet printers have made them invaluable across a wide range of industries. Let's explore some of the key sectors where these printers have become essential tools in production processes.

Food and Beverage Industry

In the food and beverage industry, continuous small character ink jet printers play a crucial role in ensuring product traceability and compliance with regulations. These printers are used to apply date codes, lot numbers, and expiration dates on various packaging types, from plastic bottles to cardboard boxes.

Pharmaceutical and Healthcare Sectors

In the pharmaceutical and healthcare industries, accurate and legible product marking is not just a regulatory requirement but a matter of patient safety. Continuous small character ink jet printers are used to apply crucial information such as batch numbers, expiration dates, and serial numbers on medication packaging, medical devices, and healthcare products.

Electronics and Electrical Engineering

The electronics and electrical engineering sectors rely heavily on continuous small character ink jet printers for component marking. These printers are used to apply serial numbers, part codes, and other identifying information on electronic components, circuit boards, and cables.

Automotive Industry

In the automotive industry, continuous small character ink jet printers are used for marking a wide range of parts and components. From engine parts to interior components, these printers apply crucial information such as part numbers, production dates, and traceability codes.

Building and Construction Materials

The building and construction materials industry also benefits significantly from continuous small character ink jet printers. These printers are used to mark products such as pipes, cables, and building materials with product information, batch numbers, and measurement markings.

Conclusion

Continuous small character ink jet printers have undeniably become essential tools in modern production environments across various industries. Their versatility, high-speed performance, precision, and adaptability make them invaluable for businesses seeking to optimize their coding and marking processes. As technology continues to advance, we can expect these printers to become even more sophisticated, offering enhanced features and capabilities to meet the evolving needs of modern manufacturing.

For businesses looking to leverage the benefits of cutting-edge continuous small character ink jet printing technology, Shenyang Faith Technology Co., Ltd. offers a range of innovative solutions. With over a decade of experience in the inkjet printing industry, Shenyang Faith Technology specializes in providing industrial UV inkjet coding and traceability system solutions tailored to meet specific industry needs. To learn more about how these advanced printing solutions can benefit your production processes, please contact us at sale01@sy-faith.com.

References

1. Smith, J. (2022). The Impact of Continuous Inkjet Technology on Modern Manufacturing. Journal of Industrial Printing, 45(3), 112-128.

2. Johnson, A. & Lee, S. (2021). Advancements in Small Character Ink Jet Printing for Product Identification. International Conference on Packaging Innovation, 78-92.

3. Brown, R. (2023). Continuous Inkjet Printing: A Comprehensive Guide for Industry Professionals. TechPress Publications.

4. Zhang, L. et al. (2020). Comparative Analysis of Coding Technologies in Food and Beverage Industry. Journal of Food Engineering, 287, 110-122.

5. Davis, M. (2022). The Role of Continuous Inkjet Printers in Ensuring Pharmaceutical Product Safety. Pharmaceutical Technology, 46(5), 28-35.

Online Message

Learn about our latest products and discounts through SMS or email

_1761190330215.jpg)