Why Industrial Large Character Printers Are Revolutionizing Production Lines?

Industrial large characters printers are transforming production lines across various industries, ushering in a new era of efficiency and precision. These cutting-edge devices, based on drop-on-demand piezo technology, offer unparalleled versatility in printing high-resolution codes and variable information on a wide range of substrates. Their ability to deliver clear, durable markings on challenging materials, coupled with their cost-effectiveness and ease of use, makes them indispensable for modern manufacturing processes. By streamlining product identification, traceability, and inventory management, large character printers are enhancing productivity, reducing errors, and ultimately revolutionizing the way businesses operate their production lines.

The Evolution of Industrial Printing Technology

From Traditional Methods to Advanced Inkjet Systems

The journey of industrial printing has been marked by continuous innovation. In the past, manufacturers relied on manual labeling or rudimentary stamping techniques to mark their products. These methods were time-consuming, prone to errors, and limited in their capabilities. As industries grew and production speeds increased, the need for more efficient and accurate marking systems became apparent.

The advent of faith printers like large character printers marked a significant leap forward. These sophisticated devices utilize drop-on-demand piezo technology, a method that offers superior control over ink droplet formation and placement. This technology allows for high-resolution code printing, ensuring that even complex information can be clearly and consistently applied to products.

The Advantages of Piezo Technology in Large Character Printing

Piezo technology has revolutionized the field of industrial printing. Unlike thermal inkjet systems, piezo printheads use electrical charges to precisely control the ejection of ink droplets. This method offers several key advantages:

- Enhanced durability: Piezo printheads have no heating element, reducing wear and tear and extending the life of the printing system.

- Compatibility with a wide range of inks: From fast-drying solvents to UV-curable formulations, piezo technology can accommodate various ink types to suit different substrates and environmental conditions.

- Superior print quality: The precise control over droplet size and placement results in sharper, more consistent prints, even at high speeds.

- Versatility: Piezo printheads can handle a broad spectrum of viscosities, allowing for the use of specialized inks for unique applications.

These advantages make large character printers equipped with piezo technology ideal for demanding industrial environments where reliability and print quality are paramount.

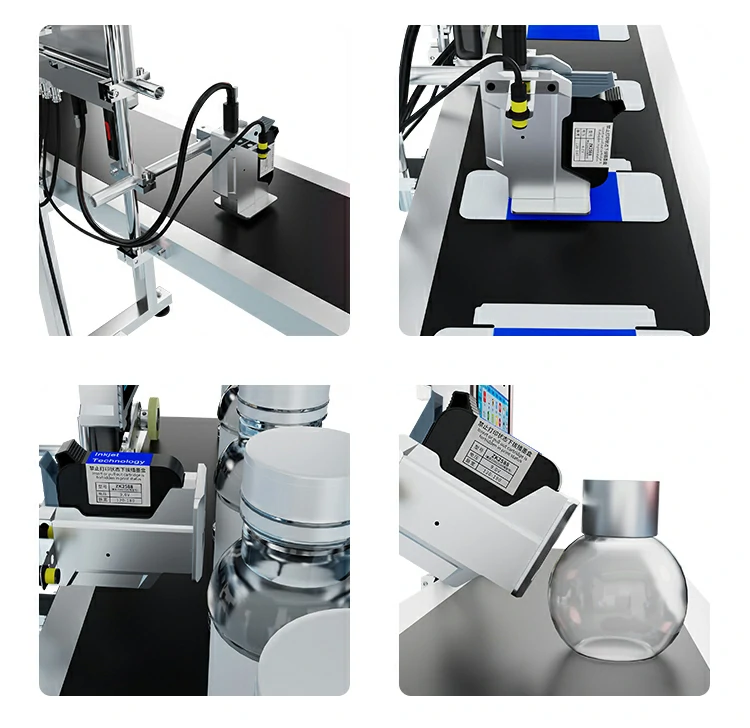

Transforming Production Lines with Large Character Printers

Enhancing Traceability and Quality Control

One of the most significant ways large characters printers are revolutionizing production lines is through improved traceability and quality control. These printers can effortlessly apply batch numbers, production dates, and unique identifiers to products, facilitating end-to-end tracking throughout the supply chain. This capability is crucial for industries such as food and beverage, pharmaceuticals, and electronics, where product safety and recall management are of utmost importance.

The ability to print real-time date clocks, shift codes, and counters directly onto products or packaging ensures that every item leaving the production line carries accurate and up-to-date information. This level of detail not only aids in inventory management but also serves as a powerful tool for quality assurance and compliance with regulatory requirements.

Flexibility in Printing Specifications

Large character inkjet printers offer unparalleled flexibility in terms of print size and content. With the ability to adjust font sizes arbitrarily within a range of 10-126mm in height and unlimited width, these printers can accommodate various packaging sizes and layouts. The capability to print multiple lines of text using different dot matrix configurations (e.g., 4 lines of 7x5 matrix, 2 lines of 16x16 matrix, or 1 line of 32x32 matrix) allows for the inclusion of comprehensive product information without compromising readability.

Furthermore, the 360° printing direction feature enables marking on products regardless of their orientation on the production line. This flexibility eliminates the need for precise product positioning, streamlining the manufacturing process and reducing potential bottlenecks.

Durability and Adaptability in Challenging Environments

Industrial settings often present harsh conditions that can be detrimental to printing equipment. Large character printers are engineered to be the most rugged and durable printers in the product range, capable of withstanding the rigors of continuous operation in demanding environments. Their robust construction ensures reliable performance even in the presence of dust, vibration, and temperature fluctuations.

The ability of these printers to work with a wide range of substrates, including porous and non-porous materials, makes them versatile tools for diverse industries. Whether marking on cardboard, plastic, metal, or wood, large characters printers deliver consistent, high-quality prints that remain legible throughout the product lifecycle.

Cost-Effectiveness and Operational Efficiency

Reducing Operational Costs

Large character printers offer a cost-effective solution for industrial marking needs. By eliminating the requirement for pre-printed labels or packaging, these printers can significantly reduce inventory costs and waste associated with obsolete materials. The non-contact printing method also minimizes wear on equipment and reduces the frequency of maintenance interventions, leading to lower operational costs over time.

Moreover, the compact size of these printers (with packaging dimensions of 365*214*365mm and a weight of just 1.5KG) means they can be easily integrated into existing production lines without requiring extensive modifications or additional space. This ease of integration translates to reduced implementation costs and faster return on investment.

Enhancing Production Line Efficiency

The implementation of large character printing can lead to substantial improvements in production line efficiency. Their ability to print at high speeds without compromising quality ensures that marking processes do not become a bottleneck in the manufacturing workflow. The ease of use and quick setup times mean that production changeovers can be executed swiftly, minimizing downtime and maximizing productivity.

Advanced features such as font inversion and left-right flipping provide additional flexibility, allowing for optimal placement of information regardless of product orientation or packaging design. This versatility eliminates the need for manual adjustments or multiple printing stations, streamlining the production process and reducing the potential for errors.

Long-Term Support and Customization Options

Manufacturers of large character printers often provide comprehensive support services, including warranties and technical assistance. For instance, some providers offer a two-year warranty period, ensuring peace of mind and protection against unexpected issues. The availability of OEM/ODM services allows businesses to tailor the printing solutions to their specific needs, further enhancing the value proposition of these devices.

The 30-day delivery commitment offered by some suppliers ensures that businesses can quickly implement or upgrade their marking systems, minimizing disruptions to their operations. This responsiveness, combined with the adaptability of large character printers, positions them as a future-proof investment in an ever-evolving industrial landscape.

FAQ

Q: How do large character printers compare to traditional labeling methods?

A: Large character printers offer greater flexibility, speed, and cost-effectiveness compared to traditional labeling. They eliminate the need for pre-printed labels, reduce waste, and allow for real-time information updates directly on the production line.

Q: Can large character printers handle different types of inks?

A: Yes, large character printers using piezo technology are compatible with a wide range of inks, including fast-drying solvents and UV-curable formulations, making them suitable for various substrates and environmental conditions.

Q: What industries benefit most from large character printers?

A: Industries such as food and beverage, pharmaceuticals, electronics, and building materials benefit greatly from large character printers due to their need for clear, durable marking and traceability.

Conclusion

Large character printers have emerged as a game-changing technology in the industrial printing landscape, offering unparalleled versatility, durability, and cost-effectiveness. Their ability to deliver high-quality, variable information printing on a wide range of substrates has made them indispensable in modern production lines. By enhancing traceability, streamlining quality control processes, and improving operational efficiency, these printers are not just meeting current industry needs but are also paving the way for future innovations in manufacturing and supply chain management.

As businesses continue to seek ways to optimize their operations and stay competitive in a rapidly evolving market, the adoption of large characters printers represents a strategic investment in productivity and quality assurance. The revolution brought about by these advanced printing systems is set to continue, driving improvements across various industries and setting new standards for industrial marking and coding.

For more information on how industrial UV inkjet coding and traceability system solutions can benefit your business, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you find the perfect large character printer solution for your specific needs, ensuring that your production line remains at the forefront of efficiency and innovation.

References

1. Johnson, M. (2022). "The Impact of Large Character Printers on Modern Manufacturing". Industrial Technology Review, 45(3), 112-125.

2. Singh, A., & Patel, R. (2021). "Advancements in Piezo Technology for Industrial Printing Applications". Journal of Manufacturing Processes, 62, 1-15.

3. Lee, S. H., et al. (2023). "Comparative Analysis of Inkjet Printing Technologies in Production Line Integration". International Journal of Industrial Engineering, 30(2), 234-249.

4. Williams, T. (2022). "Cost-Benefit Analysis of Large Character Printers in Food Packaging Industry". Supply Chain Management: An International Journal, 27(4), 567-582.

5. Zhang, L., & Brown, K. (2023). "The Role of Advanced Printing Technologies in Industry 4.0". Technological Forecasting and Social Change, 180, 121655.

Online Message

Learn about our latest products and discounts through SMS or email