Piezo Printer

PIJ materialsPIJ technology can print on a variety of materials, mainly including paper, plastic, metal, glass, fabric and wood. Various types of paper and plastic materials (such as polyethylene and PVC) are suitable for label and packaging printing, while metal and glass surfaces are used for personalized design of electronic products and decorations. The application of fabrics and wood further broadens the scope of application of PIJ technology, making it an important choice for the modern printing industry.

Our services:2-year warranty, delivery within 30 days, 7×24 hours after-sales service, and support for OEM/ODM.

Advanced Piezo Printer Technology: Professional Industrial Printing Solutions

Looking for reliable industrial printing solutions? Our Piezo Printer technology delivers exceptional performance for your marking and coding needs. Shenyang Faith Technology brings you cutting-edge piezoelectric printing frameworks planned for requesting mechanical situations. With over 10 a long time of mastery and nearness in 126 nations, our item arrangements serve more than 200,000 fulfilled clients around the world. These progressed frameworks offer exact, high-speed printing capabilities that guarantee reliable quality and strength for your generation lines.

Why Choose Our Piezoelectric Printing Systems?

Superior Print Quality and Precision

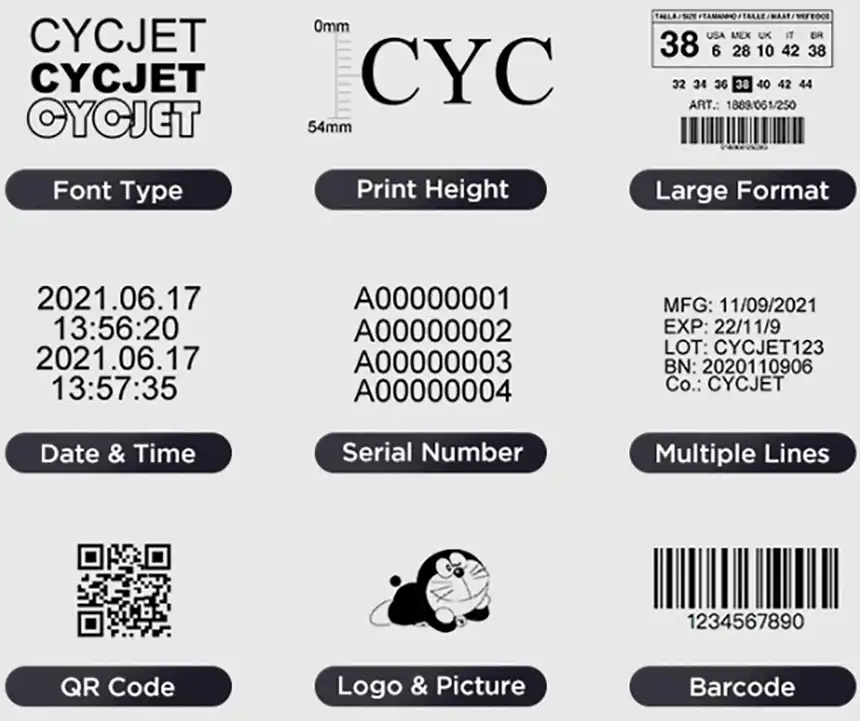

Our piezoelectric innovation guarantees fresh, clear markings each time. You get steady print quality that meets the most noteworthy industry benchmarks. The exactness control permits for nitty gritty illustrations, barcodes, and content printing with remarkable accuracy.

Versatile Application Range

These printing frameworks work flawlessly over different industries:

- Food and beverage packaging

- Pharmaceutical labeling

- Automotive parts marking

- Electronics manufacturing

- Building materials identification

- Textile printing applications

Cost-Effective Operation

You advantage from moo upkeep necessities and decreased working costs. The proficient ink utilization and long-lasting components make these frameworks profoundly conservative for persistent generation environments.

Technical Specifications

| Parameter | Specification |

|

Print Resolution |

Up to 600 DPI |

|

Print Speed |

1-300 m/min |

|

Print Height |

1-70mm adjustable |

|

Ink Types |

Water-based, solvent-based, UV-curable |

|

Operating Temperature |

-10°C to +45°C |

|

Power Supply |

AC 100-240V, 50/60Hz |

|

Communication Interface |

Ethernet, USB, RS232 |

|

Print Distance |

0.5-12mm from substrate |

|

Nozzle Configuration |

128-1024 nozzles |

|

Warranty Period |

2 years comprehensive coverage |

Advanced Features That Set Us Apart

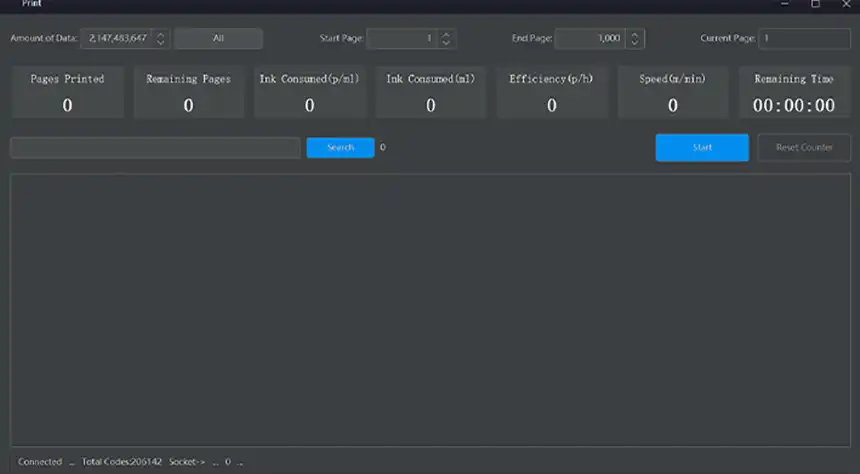

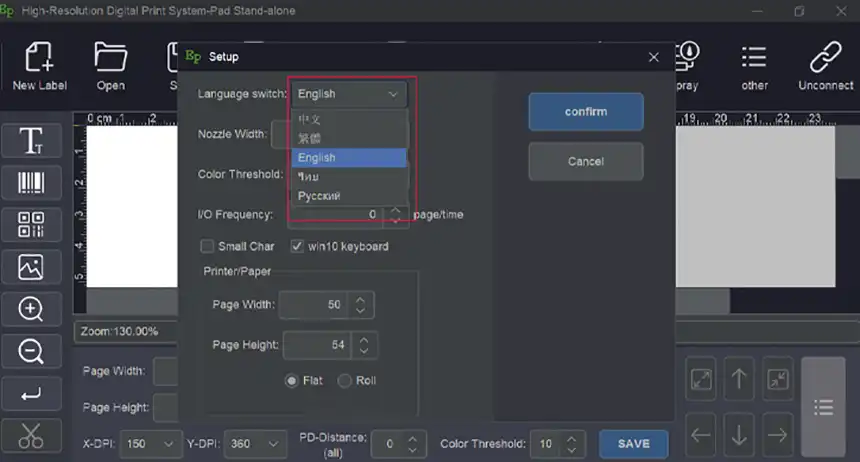

Intelligent Control System

The user-friendly interface makes operation straightforward and natural. You can effectively alter settings, screen execution, and troubleshoot issues through the touchscreen show. Real-time status checking keeps you educated almost framework performance.

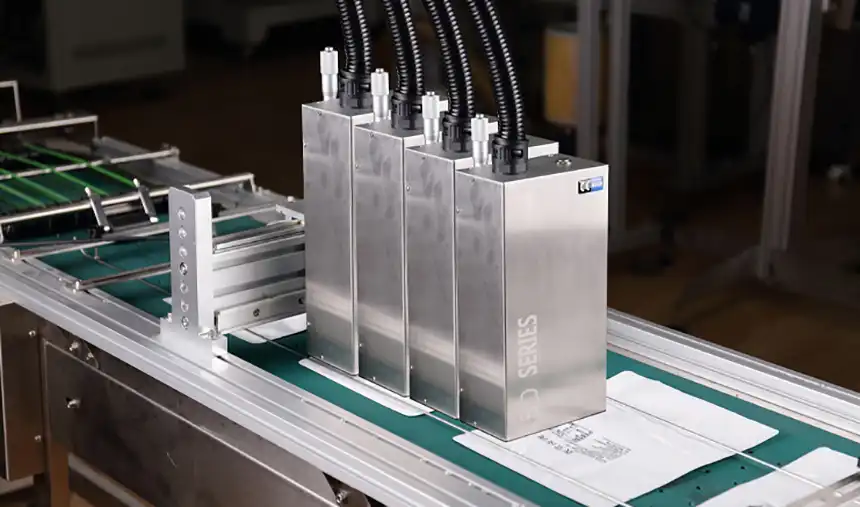

Flexible Integration Options

Our frameworks coordinated consistently with existing generation lines. The compact plan fits into tight spaces whereas keeping up full usefulness. Numerous communication conventions guarantee compatibility with different control systems.

Durable Construction

Built to withstand cruel mechanical situations, these printers keep up reliable execution beneath challenging conditions. The strong development guarantees long-term unwavering quality and negligible downtime.

Industries We Serve

Manufacturing Excellence

Production facilities worldwide trust our printing technology for quality marking solutions. The Piezo Printer frameworks handle high-volume generation necessities whereas keeping up reliable yield quality.

Packaging and Labeling

Food handling, pharmaceutical, and shopper merchandise companies depend on our innovation for administrative compliance and brand assurance. The exact checking capabilities guarantee precise item distinguishing proof and traceability.

Quality Control and Traceability

Manufacturing quality frameworks advantage from changeless, neat markings that bolster total item traceability all through the supply chain.

|

|

|

|

|

|

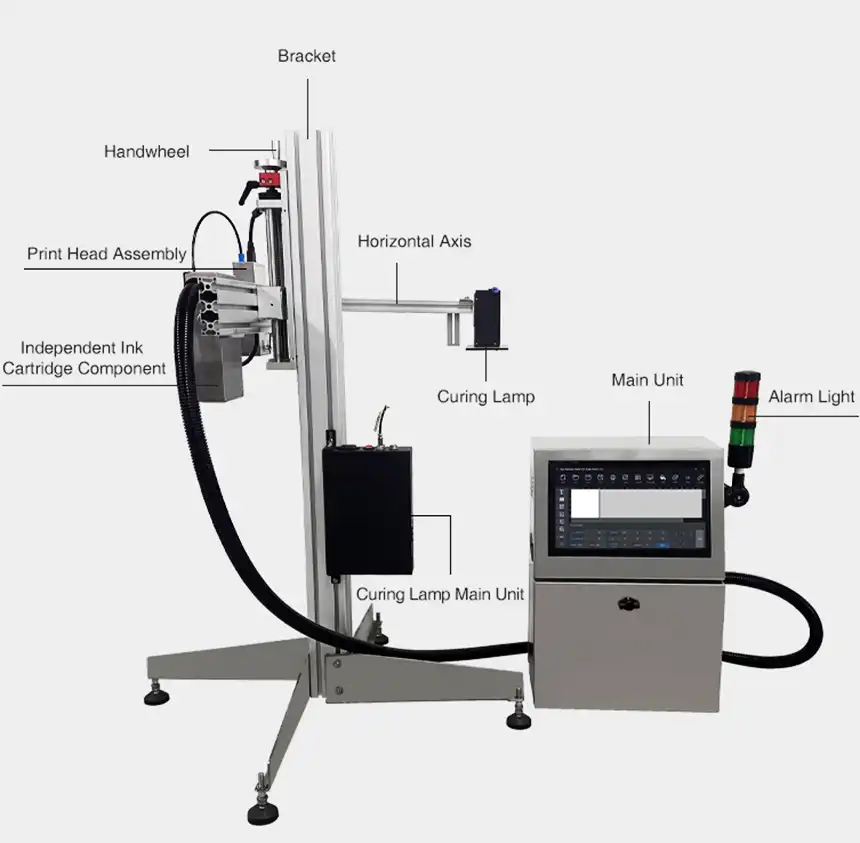

| Supports 360-degree printing. The print head assembly regulator features multidimensionaladjustment, allowing for up-and-down, side-to-side, and angleadjustments. This high flexibility meets the more complexneeds of customers. |

Eco-friendly ink. Uses eco-friendly UV ink that has passed ROHS certificationand provides a detailed MSDS report. lt adapts to differentmaterials and meets reauirements for adhesion. alcoholresistance, and high/ow-temperature durability, aligning withfuture environmental trends. UV ink offers excellent adhesionand long-lasting color performance. |

New print head anti-clogging technologymaintains print head humidity. Equipped with a print head cleaning function and features delayed spray for reduced maintenance costs, enhancingequipment stability and ensuring reliable quality |

Powerful network communication capabilities Equipped with a network protocol communication interfacethat can connect and communicate with ERP, MES systemsand various specialized software, enabling various complexidentification applications. |

Operating interface Convenient information editing is facilitated by a 13.3-inch1080P industrial-grade touchscreen. The new user interfaceallows for direct editing of various text graphics and variabledata such as 2D barcodes. Additionally, content can be directlyuploaded via USB interface or network protocol |

Installation and Support Services

Professional Installation

Our technical team provides complete installation services to ensure optimal system performance. We handle setup, calibration, and initial training to get your Piezo Printer running efficiently.

Comprehensive Training

Your administrators get exhaustive preparing on framework operation, support strategies, and investigating procedures. This guarantees most extreme efficiency and negligible operational issues.

Ongoing Technical Support

We give free specialized back and data to offer assistance you keep up top framework execution. Our worldwide benefit organize guarantees fast reaction times when you require assistance.

Quality Assurance and Warranty

Two-Year Comprehensive Warranty

Every framework incorporates a total 2-year guarantee covering parts, labor, and specialized bolster. This illustrates our certainty in item quality and commitment to client satisfaction.

Rigorous Quality Control

Our cutting edge 2,500 m² fabricating office keeps up strict quality benchmarks all through the generation prepare. Each framework experiences broad testing some time recently shipment.

Continuous Innovation

With over a decade of industry encounter, we ceaselessly move forward our innovation to meet advancing advertise requests and client requirements.

Frequently Asked Questions

Q: What types of inks can I use with piezoelectric printing systems?

A: You can use various ink formulations including water-based, solvent-based, and UV-curable inks. The system accommodates different ink viscosities and chemical compositions to match your specific application requirements.

Q: How often does the system require maintenance?

A: Regular maintenance involves daily cleaning cycles and weekly inspection routines. Major maintenance typically occurs every 6-12 months depending on usage intensity and environmental conditions.

Q: Can the printer handle curved or irregular surfaces?

A: Yes, the adjustable print distance and flexible nozzle configuration allow printing on various surface geometries including curved, textured, and irregular substrates.

Q: What training do operators need?

A: Basic operation training takes 2-4 hours for experienced personnel. Complete training including maintenance procedures typically requires 1-2 days depending on operator experience and system complexity.

Q: How do I ensure consistent print quality?

A: Regular calibration, proper ink management, and adherence to maintenance schedules ensure consistent results. The built-in quality monitoring systems alert you to any performance variations.

Q: What's the expected lifespan of the printing heads?

A: With proper maintenance, printing heads typically last 12-24 months in standard industrial applications. Lifespan varies based on ink types, operating conditions, and usage patterns.

Get Started Today

Ready to enhance your production line with reliable Piezo Printer technology? Our experienced group stands prepared to offer assistance you select the idealize printing arrangement for your particular needs. We give total discussion administrations to guarantee you get the most reasonable framework configuration.

contact us nowadays for nitty gritty details, estimating data, and custom arrangement choices. Our specialized specialists will work with you to plan a arrangement that meets your correct necessities whereas remaining inside your budget parameters.

Contact Information:

Email: sale01@sy-faith.com

Transform your mechanical stamping and coding operations with demonstrated piezoelectric printing innovation. Connect over 200,000 fulfilled clients around the world who believe our arrangements for their basic printing applications. Encounter the distinction that quality designing and devoted bolster make in your generation environment.

Online Message

Learn about our latest products and discounts through SMS or email

_1756447852321.jpg)