Printer Inkjet Piezo

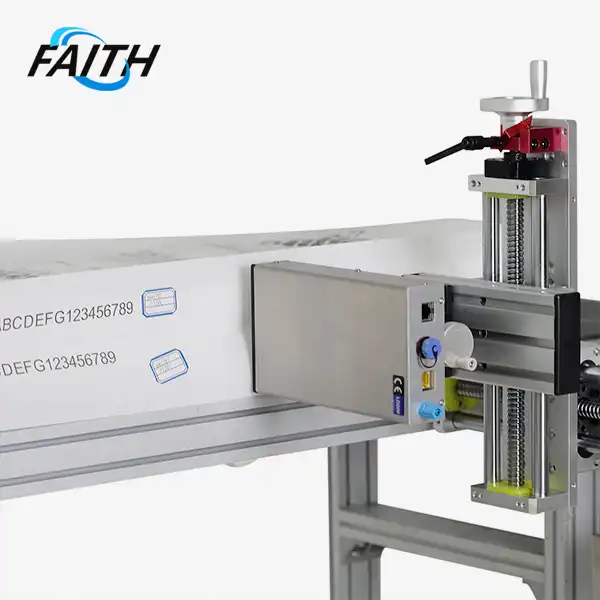

It is suitable for direct, high-contrast coding and marking on absorbent and porous surfaces such as wood, cardboard and paper with variable print height.

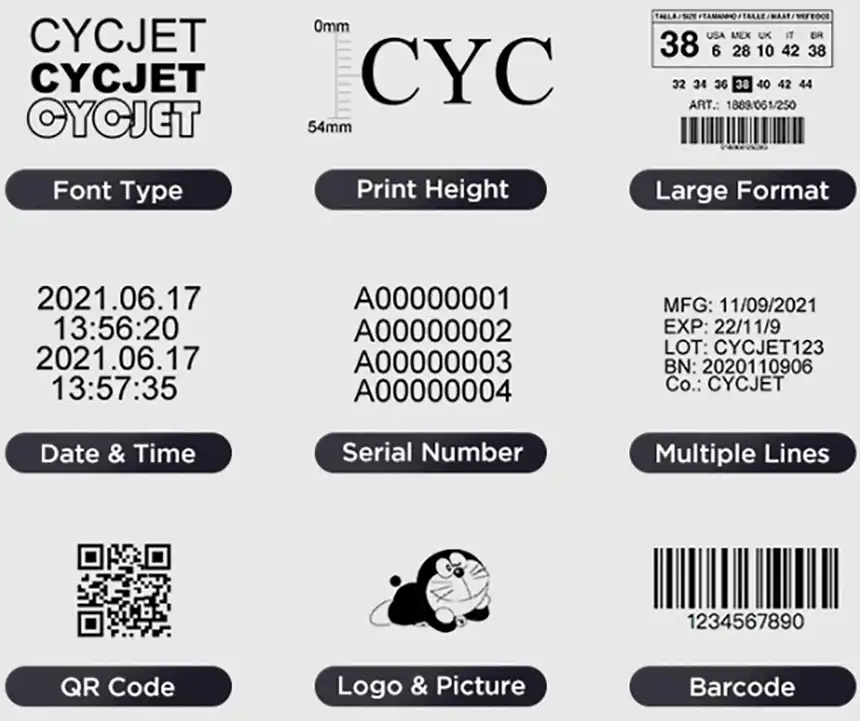

Piezo inkjet printers are the preferred solution for printing high-quality text, graphics and barcodes on almost any material.

Our services:2-year warranty, delivery within 30 days, 7×24 hours after-sales service, and support for OEM/ODM.

Professional Printer Inkjet Piezo Technology Solutions

Looking for reliable, high-performance printing solutions? Our Printer Inkjet Piezo innovation conveys uncommon accuracy and toughness for mechanical applications. With over 10 a long time of skill in creating piezoelectric inkjet frameworks, Shenyang Confidence Innovation brings you cutting-edge printing arrangements that serve more than 200,000 clients over 126 nations. Our item frameworks combine progressed designing with user-friendly operation, guaranteeing your commerce accomplishes steady, proficient comes about each time.

Whether you're checking items, coding bundling, or taking care of complex printing errands, our piezoelectric innovation adjusts to your particular needs whereas keeping up prevalent print quality and operational efficiency.

Why Choose Piezoelectric Inkjet Technology?

Precision Engineering at Its Best

Piezoelectric printheads utilize exact electrical beats to control ink bead arrangement. This innovation guarantees reliable bead measure and arrangement, coming about in sharp, clear prints each time. You get professional-quality yield without the upkeep cerebral pains of conventional printing methods.

Versatile Ink Compatibility

Our frameworks work consistently with different ink sorts, including:

- Solvent-based inks

- Water-based formulations

- UV-curable inks

- Specialty industrial inks

This adaptability implies you can select the culminate ink for your particular application without compromising performance.

Built for Industrial Environments

Designed to withstand demanding conditions, our Printer Inkjet Piezo heads stand up to clogging and keep up steady execution. You'll encounter negligible downtime and diminished support costs, keeping your operations running smoothly.

Technical Specifications

| Parameter | Specification |

|

Print Resolution |

Up to 600 DPI |

|

Operating Temperature |

-10°C to +50°C |

|

Humidity Range |

10% to 85% RH |

|

Print Speed |

Up to 300 m/min |

|

Ink Viscosity Range |

3-20 cP |

|

Nozzle Configuration |

16-256 nozzles |

|

Drop Volume |

1-42 pL |

|

Power Consumption |

50-150W |

|

Connectivity |

USB, Ethernet, RS232 |

|

Warranty Period |

2 Years |

Applications Across Industries

Manufacturing and Production

Mark serial numbers, generation dates, and clump codes specifically onto items. Our piezoelectric innovation guarantees lasting, clear markings that withstand cruel mechanical conditions.

Food and Beverage Packaging

Print close dates, parcel numbers, and administrative data on different bundling materials. The framework handles high-speed generation lines whereas keeping up print quality consistency.

Electronics and Components

Create exact markings on circuit sheets, components, and electronic lodgings. The fine bead control permits for nitty gritty printing on little surfaces without compromising functionality.

Pharmaceutical Industry

Ensure traceability with clear, changeless coding on pharmaceutical bottles, rankle packs, and restorative gadgets. Our item innovation meets strict pharmaceutical stamping requirements.

Advanced Features and Benefits

Smart Droplet Control

Our exclusive control framework alters bead arrangement in real-time, compensating for natural changes and guaranteeing reliable print quality all through your generation run.

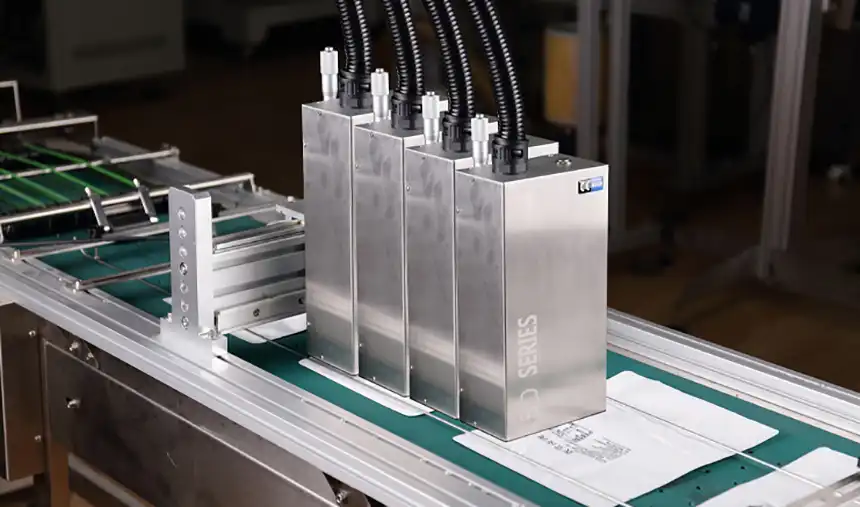

Easy Integration

Compatible with existing generation lines, our frameworks coordinated easily without requiring major adjustments. You can begin profiting from moved forward printing capabilities rapidly and efficiently.

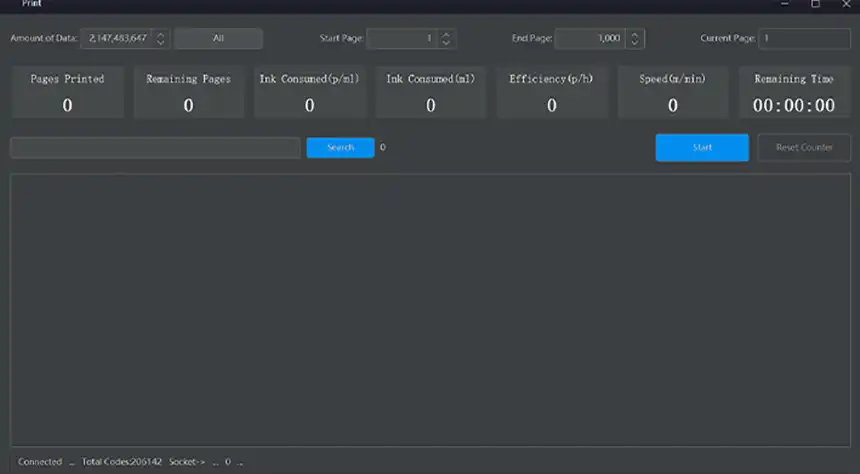

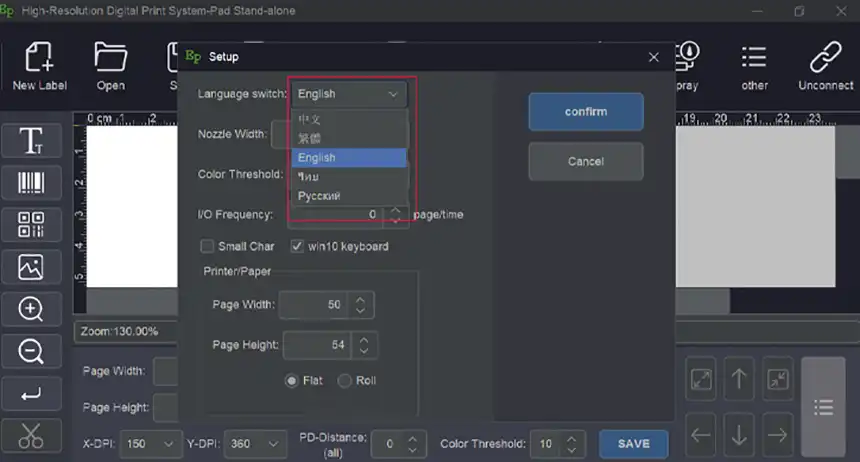

User-Friendly Interface

Intuitive touchscreen controls make operation basic for your group. Pre-programmed formats and simple work setup decrease preparing time and minimize administrator errors.

Remote Monitoring Capability

Monitor framework execution, ink levels, and upkeep plans remotely. This proactive approach anticipates unforeseen downtime and optimizes your printing operations.

Quality Assurance and Support

Comprehensive Testing Standards

Every Printer Inkjet Piezo framework experiences thorough testing some time recently shipment. We confirm print quality, solidness, and execution beneath different working conditions to guarantee you get a dependable product.

Global Technical Support

Our specialized group gives free back and direction for establishment, operation, and upkeep. With clients in 126 nations, we get it assorted operational prerequisites and can help with localized solutions.

Training and Documentation

Comprehensive preparing materials and nitty gritty documentation offer assistance your group maximize framework execution. We give both on-site and farther preparing alternatives to suit your plan and preferences.

Cost-Effective Operation

Reduced Maintenance Requirements

Piezoelectric innovation requires less visit cleaning and support compared to other printing strategies. This deciphers to lower operational costs and made strides efficiency for your business.

Efficient Ink Usage

Precise bead control minimizes ink squander whereas keeping up fabulous print quality. You'll see noteworthy fetched investment funds on consumables without compromising yield quality.

Long Service Life

Built with high-quality components and supported by our 2-year guarantee, our frameworks provide solid execution for a long time. The strong plan guarantees steady operation indeed in challenging mechanical environments.

|

|

|

|

|

|

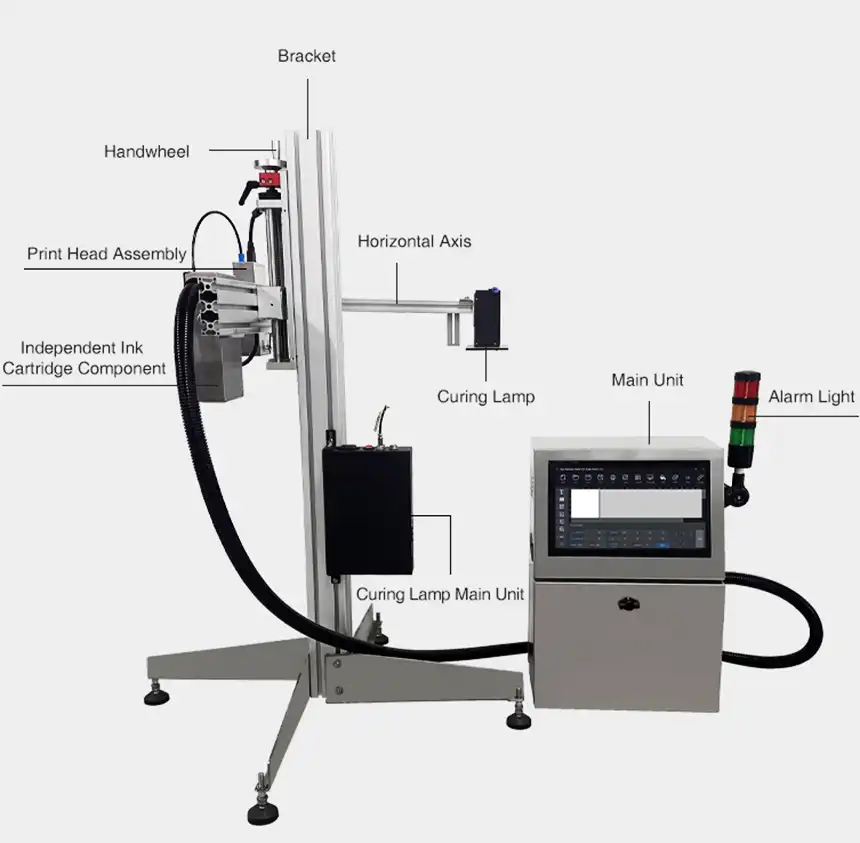

| Supports 360-degree printing. The print head assembly regulator features multidimensionaladjustment, allowing for up-and-down, side-to-side, and angleadjustments. This high flexibility meets the more complexneeds of customers. |

Eco-friendly ink. Uses eco-friendly UV ink that has passed ROHS certificationand provides a detailed MSDS report. lt adapts to differentmaterials and meets reauirements for adhesion. alcoholresistance, and high/ow-temperature durability, aligning withfuture environmental trends. UV ink offers excellent adhesionand long-lasting color performance. |

New print head anti-clogging technologymaintains print head humidity. Equipped with a print head cleaning function and features delayed spray for reduced maintenance costs, enhancingequipment stability and ensuring reliable quality |

Powerful network communication capabilities Equipped with a network protocol communication interfacethat can connect and communicate with ERP, MES systemsand various specialized software, enabling various complexidentification applications. |

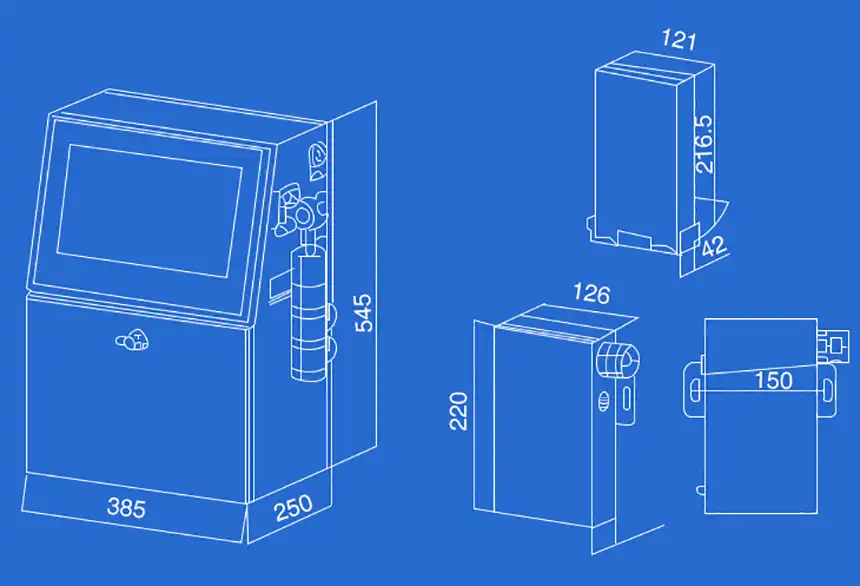

Operating interface Convenient information editing is facilitated by a 13.3-inch1080P industrial-grade touchscreen. The new user interfaceallows for direct editing of various text graphics and variabledata such as 2D barcodes. Additionally, content can be directlyuploaded via USB interface or network protocol. |

Frequently Asked Questions

Q: How does piezoelectric technology differ from thermal inkjet printing?

A: Piezoelectric frameworks utilize electrical beats to make weight waves that launch ink beads, whereas warm frameworks utilize warm. This makes our Item innovation more flexible with ink sorts and gives longer printhead life.

Q: What maintenance is required for piezoelectric printheads?

A: Customary cleaning cycles and intermittent spout checks are regularly adequate. Our frameworks incorporate robotized support highlights that minimize manual intercession and keep your printer working optimally.

Q: Can I use custom inks with your piezoelectric systems?

A: Yes, our frameworks suit different ink details. We can offer assistance assess your particular ink necessities and guarantee compatibility with our printing technology.

Q: How quickly can I integrate this technology into my existing production line?

A: Integration regularly takes 1-3 days depending on your setup complexity. Our specialized group gives establishment back and guarantees negligible disturbance to your operations.

Q: What training do my operators need?

A: Basic training usually takes 4-8 hours. The intuitive interface makes operation straightforward, and we provide comprehensive training materials and ongoing support.

Get Started Today

Ready to upgrade your printing capabilities? Our piezoelectric inkjet arrangements offer the unwavering quality, accuracy, and adaptability your commerce needs. With demonstrated execution over assorted businesses and comprehensive back backing each framework, you can certainly overhaul your printing operations.

Contact our expert team at sale01@sy-faith.com to discuss your specific requirements and discover how our advanced printing technology can benefit your business. Let us help you achieve superior results with our proven Printer Inkjet Piezo solutions.

Online Message

Learn about our latest products and discounts through SMS or email

(2)_1732610826389.webp)