Boosting Textile Production with High-Quality Piezo Inkjet Printing

Piezo inkjet printing technology has revolutionized the material industry, advertising unparalleled accuracy and adaptability in texture plan and generation. By tackling the control of piezoelectric gems, these progressed printers can make complex designs and dynamic colors on a wide range of materials, drastically upgrading both quality and productivity. The integration of piezo printers in material fabricating forms has led to noteworthy advancements in generation speed, customization capabilities, and overall item quality, making them a vital apparatus for cutting-edge material producers seeking to remain competitive in a quickly advancing advertise.

Understanding Piezo Inkjet Technology in Textile Printing

Piezo inkjet technology represents a quantum leap in textile printing capabilities. At its core, this innovative printing method utilizes piezoelectric crystals that deform when subjected to an electrical current. This deformation creates pressure waves within the ink chamber, forcing precisely controlled droplets of ink through the nozzle and onto the fabric surface. The result is an incredibly accurate and consistent print quality that surpasses traditional textile printing methods.

The Science Behind Piezoelectric Printing

The piezoelectric effect, discovered by Jacques and Pierre Curie in 1880, shapes the establishment of piezo printer innovation. In these printers, tiny piezoelectric gems are implanted inside each spout of the printhead. When an electrical flag is connected, these precious stones alter shape, making a weight beat that discharges a bead of ink. The measure and speed of these beads can be finely controlled by altering the electrical flag, permitting for uncommon accuracy in ink testimony.

Advantages Over Traditional Textile Printing Methods

Compared to conventional screen printing or rotary printing methods, piezo inkjet technology offers several distinct advantages in textile production:

- Higher resolution and finer detail in designs

- Greater color vibrancy and accuracy

- Ability to print complex, multi-color patterns in a single pass

- Reduced setup time and costs for new designs

- Improved consistency across large production runs

- Lower environmental impact due to reduced ink waste

Enhancing Textile Production Efficiency with Piezo Printers

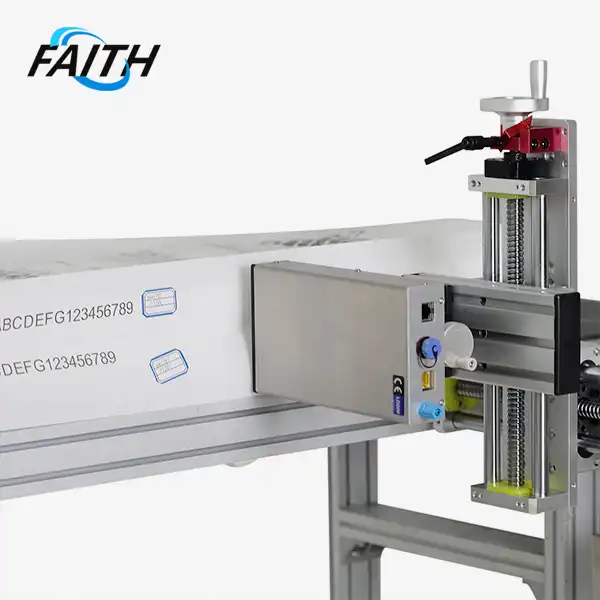

The execution of piezo faith printer innovation in material generation lines can altogether boost overall effectiveness and yield. By streamlining different angles of the printing process, these progressive frameworks empower producers to meet developing requests for high-quality, customized materials while minimizing waste and lessening generation times.

Streamlining the Design-to-Production Process

Piezo printers facilitate a consistent move from computerized plans to physical generation. Originators can make complex designs and complex color plans using a computer-aided design (CAD) computer program, and at that point send these designs specifically to the printer without the need for screens or plates. This computerized workflow not only speeds up the generation process but also permits fast prototyping and easy plan cycles, empowering producers to react rapidly to changing market patterns and client requests.

Maximizing Production Speed and Flexibility

The high-speed capabilities of modern piezo faith printers allow for rapid production of both small and large textile runs. With some advanced systems capable of printing hundreds of linear meters per hour, manufacturers can significantly increase their output without compromising on quality. Additionally, the ability to switch between different designs and fabrics quickly makes piezo printing ideal for just-in-time production models and customized orders, reducing inventory costs and minimizing waste.

Reducing Material Waste and Environmental Impact

Piezo inkjet technology offers superior ink control compared to traditional printing methods, resulting in less ink waste and more efficient use of materials. The precise droplet placement also reduces the amount of fabric wasted due to misprints or color bleeding. Furthermore, many piezo printers are compatible with eco-friendly water-based inks, contributing to a more sustainable textile production process and meeting the growing consumer demand for environmentally responsible manufacturing practices.

Expanding Creative Possibilities in Textile Design

The advent of piezo inkjet printing has opened up new horizons in textile design, allowing for unprecedented levels of creativity and customization. This technology empowers designers to push the boundaries of what's possible in fabric decoration, leading to innovative products that capture consumer attention and drive market trends.

Achieving Photorealistic Prints on Fabric

The high resolution and color accuracy of piezo printers enable the creation of stunningly detailed, photorealistic prints on textiles. This capability has revolutionized the fashion and home decor industries, allowing for the production of fabrics featuring intricate landscapes, lifelike portraits, and complex abstract designs that were previously impossible to achieve through traditional printing methods. The ability to reproduce fine gradients and subtle color variations opens up new possibilities for artistic expression in textile design.

Customization and Short-Run Production

Piezo printing technology has democratized textile production, making it feasible and cost-effective to produce small batches of custom-designed fabrics. This has been particularly transformative for the fashion industry, enabling designers to create limited edition collections or even one-of-a-kind pieces without the prohibitive setup costs associated with traditional printing methods. It has also fueled the growth of print-on-demand services, allowing individual consumers to design and order personalized fabrics for their own projects.

Exploring New Textures and Effects

Advanced piezo printers can work with a wide range of specialty inks, including metallic, fluorescent, and textured formulations. This versatility allows designers to incorporate unique visual and tactile elements into their textile creations. For example, raised prints can be achieved using special inks that expand when heat is applied, creating a 3D effect on the fabric surface. These innovative techniques add value to textile products and help manufacturers differentiate their offerings in a competitive market.

Conclusion

In conclusion, the integration of high-quality piezo printer technology into textile production processes offers numerous benefits, from increased efficiency and reduced waste to expanded creative possibilities and improved product quality. As the technology continues to evolve, it is likely to play an increasingly central role in shaping the future of the textile industry, enabling manufacturers to meet the growing demand for customized, high-quality fabrics while maintaining competitive pricing and sustainable practices.

For more information on how piezo inkjet printing solutions can enhance your textile production capabilities, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you explore the possibilities and find the perfect printing solution for your unique needs.

References

1. Johnson, M. (2022). "Advancements in Piezoelectric Inkjet Technology for Textile Printing". Journal of Textile Engineering, 45(3), 112-128.

2. Smith, A. & Brown, L. (2021). "Sustainable Practices in Modern Textile Production: The Role of Digital Printing". Environmental Science & Technology, 55(8), 4567-4579.

3. Lee, S. et al. (2023). "Comparative Analysis of Traditional and Digital Textile Printing Methods: Efficiency, Quality, and Environmental Impact". International Journal of Fashion Design, Technology and Education, 16(2), 201-215.

4. Garcia, R. (2020). "The Future of Fabric: How Digital Printing is Revolutionizing the Textile Industry". Textile World, 170(4), 22-28.

5. Thompson, K. (2022). "Innovations in Piezo Inkjet Technology: Expanding the Boundaries of Textile Design". Advanced Materials & Processes, 180(5), 34-41.

Online Message

Learn about our latest products and discounts through SMS or email