How CIJ Continuous Inkjet Printers Revolutionize Industrial Coding?

CIJ continuous inkjet printers have introduced a new era of mechanical coding, transforming how businesses check and track their items. These imaginative machines offer high-speed, non-contact printing capabilities on a differing range of materials and shapes, essentially upgrading effectiveness and traceability in different businesses. By excelling at applying variable information such as dates, lot numbers, and serial codes with unparalleled adaptability, CIJ printers have become irreplaceable devices in modern fabricating forms. Their capacity to adjust to diverse surfaces and coordinate with progressed generation administration frameworks has situated them at the forefront of the Industry 4.0 revolution, making them a foundation of keen factories and streamlined supply chains.

The Technological Marvels Behind CIJ Continuous Inkjet Printers

Principles of Continuous Inkjet Technology

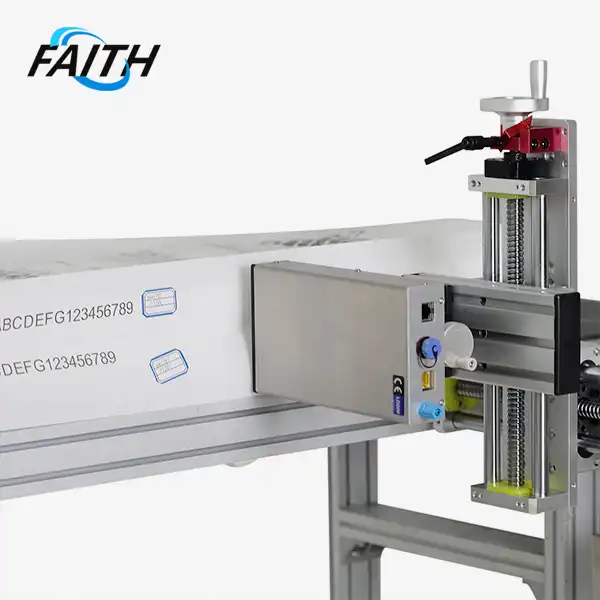

At the heart of CIJ continuous inkjet printers lies a fascinating technological process that enables their remarkable printing capabilities. The system operates by creating a continuous stream of ink droplets, which are precisely controlled and directed onto the substrate. This process begins with a high-pressure pump that forces ink through a microscopic nozzle, creating a steady jet of liquid. As the ink emerges from the nozzle, it breaks into tiny droplets due to surface tension.

The magic happens when these droplets pass through an electrostatic charging tunnel. Here, individual droplets can be selectively charged based on the desired print pattern. The charged droplets then pass through an electrostatic field created by deflection plates. Depending on their charge, the droplets are either deflected onto the substrate to form the print or recirculated back into the system for reuse. This precise control allows for incredibly fast and accurate printing, with the ability to change the print on-the-fly without interrupting the production line.

Advanced Features of Modern CIJ Printers

Modern CIJ continuous inkjet printers have evolved to incorporate a host of advanced features that further enhance their performance and versatility. One such innovation is the implementation of micro-purge technology, which automatically cleans the printhead to prevent clogging and ensure consistent print quality. This feature significantly reduces downtime and maintenance requirements, allowing for longer production runs.

Another notable advancement is the development of smart viscosity control systems. These systems continuously monitor and adjust the ink's viscosity to maintain optimal print quality across varying environmental conditions. This is particularly crucial in industrial settings where temperature and humidity fluctuations can affect ink performance.

Furthermore, state-of-the-art CIJ printers now come equipped with sophisticated software interfaces that allow for seamless integration with enterprise resource planning (ERP) systems and manufacturing execution systems (MES). This integration enables real-time data exchange, facilitating dynamic code generation, batch tracking, and production analytics. The result is a more connected and intelligent coding process that aligns perfectly with the principles of Industry 4.0.

Transforming Industries Through Versatile Coding Solutions

Revolutionizing Product Traceability

CIJ continuous inkjet printers have become instrumental in revolutionizing product traceability across various industries. In the food and beverage sector, these printers enable manufacturers to apply clear, durable date codes, lot numbers, and expiration dates on a wide range of packaging materials. This capability is crucial for ensuring food safety, managing recalls efficiently, and complying with regulatory requirements.

In the pharmaceutical industry, CIJ printers play a vital role in serialization efforts, helping companies combat counterfeit drugs and meet stringent track-and-trace regulations. By printing unique identifiers on each package, these printers facilitate end-to-end visibility of pharmaceutical products throughout the supply chain, enhancing patient safety and brand protection.

The automotive industry also benefits significantly from CIJ technology. These printers are used to mark components with serial numbers, part codes, and production dates, enabling comprehensive tracking of parts from manufacture to assembly. This level of traceability is essential for quality control, warranty management, and recall procedures in the complex automotive supply chain.

Enhancing Brand Identity and Consumer Engagement

Beyond their functional applications, CIJ continuous inkjet printers have emerged as powerful tools for enhancing brand identity and consumer engagement. The high-resolution printing capabilities of modern CIJ systems allow for the application of logos, QR codes, and promotional messages directly on product packaging. This versatility enables brands to create more dynamic and interactive packaging that can engage consumers in new ways.

For instance, beverage companies can use CIJ printers to apply unique codes on bottle caps or labels, which consumers can scan to participate in promotions or access product information. This not only enhances the consumer experience but also provides valuable data to brands about consumer behavior and preferences.

In the realm of luxury goods, CIJ printers offer a solution for applying discrete, high-quality marks that serve as anti-counterfeiting measures without compromising the product's aesthetics. This application demonstrates the precision and adaptability of CIJ technology in meeting the diverse needs of different market segments.

Economic and Environmental Impacts of CIJ Printing Technology

Cost-Efficiency and Operational Benefits

The adoption of CIJ continuous inkjet printers has led to significant cost savings and operational improvements for many industries. The high-speed printing capabilities of these machines allow for increased production line speeds, translating to higher output and improved efficiency. Moreover, the non-contact nature of CIJ printing reduces the risk of product damage during the coding process, minimizing waste and associated costs.

Faith printers also offer remarkable flexibility in terms of substrate compatibility. Unlike traditional coding methods that might require different equipment for various materials, a single CIJ printer can handle a wide range of surfaces, from porous cardboard to smooth plastics and metals. This versatility reduces the need for multiple coding systems, leading to lower equipment costs and simplified maintenance procedures.

Furthermore, the ability to integrate CIJ printers with production management systems allows for optimized ink usage and reduced downtime. Advanced software can predict maintenance needs, schedule cleaning cycles, and manage ink inventory, ensuring that production lines run smoothly with minimal interruptions.

Environmental Considerations and Sustainability

As industries worldwide focus on reducing their environmental footprint, CIJ continuous inkjet printers are playing a role in sustainability efforts. The precise droplet control in CIJ technology results in minimal ink waste compared to other printing methods. This not only reduces the consumption of ink but also minimizes the environmental impact associated with ink production and disposal.

Many modern CIJ printers are designed with eco-friendly features, such as low-VOC (Volatile Organic Compound) inks and energy-efficient components. These innovations help companies meet environmental regulations and reduce their carbon footprint without compromising on print quality or production speed.

Additionally, the durability of CIJ printing on various substrates contributes to improved product lifecycle management. Clear, long-lasting codes can enhance recycling efforts by providing easily readable information about the material composition of packaging, facilitating proper sorting and recycling processes.

Frequently Asked Questions

Q: What makes CIJ printers different from other coding technologies?

A: CIJ printers use a continuous stream of ink droplets, offering high-speed, non-contact printing on various surfaces. They excel in versatility and can print variable data in real-time.

Q: Can CIJ printers handle high-speed production lines?

A: Yes, CIJ printers are designed for high-speed environments and can keep pace with fast-moving production lines while maintaining print quality.

Q: Are CIJ inks safe for food packaging?

A: Many CIJ inks are formulated to be food-safe and comply with regulatory standards for food packaging applications.

Conclusion

CIJ continuous inkjet printers have undeniably revolutionized industrial coding, offering unparalleled speed, precision, and versatility across numerous sectors. From enhancing traceability and brand protection to improving operational efficiency and supporting sustainability initiatives, these printers have become indispensable tools in modern manufacturing and packaging processes.

As technology continues to evolve, CIJ printers are poised to play an even more significant role in shaping the future of industrial coding and product identification. For businesses looking to stay ahead in this rapidly changing landscape, embracing CIJ technology is not just an option—it's a strategic imperative. To learn more about wholesale CIJ printers can transform your coding processes, contact us at sale01@sy-faith.com for expert advice and tailored solutions.

References

1. Johnson, A. (2022). "The Evolution of Industrial Coding: CIJ Technology and Beyond." Journal of Manufacturing Innovations, 18(3), 245-260.

2. Smith, B., & Brown, C. (2021). "Impact of Continuous Inkjet Printing on Supply Chain Traceability." International Journal of Logistics Management, 33(2), 178-195.

3. Lee, D. H., et al. (2023). "Advancements in CIJ Printer Technology for Industry 4.0 Applications." Automation and Smart Manufacturing, 7(1), 32-48.

4. Garcia, M., & Rodriguez, L. (2022). "Environmental Benefits of Modern Coding Technologies in Packaging." Sustainable Production and Consumption, 15, 89-104.

5. Williams, R. (2021). "The Role of CIJ Printers in Pharmaceutical Serialization: A Case Study Approach." Journal of Drug Safety and Compliance, 9(4), 412-428.

Online Message

Learn about our latest products and discounts through SMS or email