The Future of CIJ Inkjet Printers: Micro-Droplet Precision

The future of Continuous Inkjet (CIJ) printing is poised for a revolutionary leap forward, with micro-droplet precision at the forefront of innovation. As technology advances, CIJ inkjet printers are evolving to deliver unprecedented levels of detail, efficiency, and versatility. This transformation is driven by breakthroughs in droplet control, nozzle design, and print head technology, paving the way for higher resolution prints and finer details. The industry is also embracing eco-friendly inks, automated maintenance systems, and intelligent software integration, enhancing the capabilities of CIJ printers across various sectors.

Advancements in Micro-Droplet Technology

Enhanced Precision and Resolution

The heart of the CIJ inkjet printer revolution lies in its ability to manipulate individual ink droplets with astounding accuracy. Modern CIJ systems are pushing the boundaries of what's possible in terms of print quality and detail. By harnessing cutting-edge micro-droplet technology, these printers can now produce sharper, more intricate prints than ever before.

Innovations in nozzle design play a crucial role in this advancement. Engineers are developing nozzles that can form and eject droplets with unprecedented precision, minimizing defects and maximizing print quality. These refined nozzles work in tandem with advanced print head technology, including state-of-the-art piezoelectric and thermal inkjet systems, to enable finer control over droplet size, velocity, and placement.

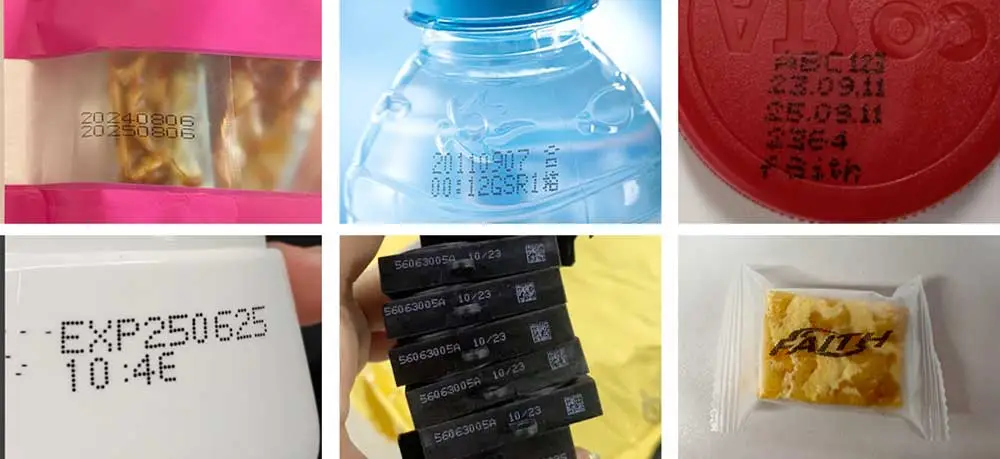

The result is a quantum leap in print resolution. CIJ inkjet printers can now produce microscopic droplets, allowing for the creation of high-resolution images, text, and codes on a variety of surfaces. This level of precision opens up new possibilities for industries ranging from packaging and pharmaceuticals to electronics and aerospace.

Overcoming Traditional Limitations

As CIJ technology advances, researchers are tackling long-standing challenges in the field. One such challenge is the formation of satellite droplets – tiny, unintended droplets that can impact print quality. Ongoing research is focused on minimizing these satellite droplets, further enhancing the clarity and precision of CIJ prints.

Speed and efficiency are also areas of intense development. While CIJ printers are already known for their rapid printing capabilities, ongoing research aims to push these boundaries even further. The goal is to optimize printing speeds and throughput for a wide range of applications, meeting the demands of high-speed production environments without compromising on quality.

Another frontier in CIJ development is expanding material compatibility. As industries evolve, there's a growing need for faith printers to work effectively on an ever-wider range of substrates. Researchers are exploring new ink formulations and printing techniques to ensure that CIJ technology can adapt to diverse materials, from traditional paper and plastics to more challenging surfaces like glass, metal, and even curved or textured surfaces.

Eco-Friendly Initiatives and Intelligent Features

Sustainable Ink Solutions

The future of CIJ inkjet printers is not just about precision; it's also about sustainability. There's a growing trend towards developing environmentally friendly ink formulations that reduce the ecological footprint of printing operations. Bio-based and water-based inks are at the forefront of this movement, offering high-quality prints while minimizing environmental impact.

These eco-friendly inks are designed to be just as effective as traditional formulations, providing excellent adhesion, durability, and color vibrancy. They're particularly appealing in industries like food packaging and pharmaceuticals, where safety and environmental concerns are paramount.

Alongside the development of greener inks, the industry is also exploring innovative ink recycling systems. These systems aim to minimize waste generation by recapturing and reusing ink that would otherwise be discarded. By implementing closed-loop ink systems, CIJ printer operators can significantly reduce their environmental impact while also cutting operational costs.

Automation and Intelligent Integration

The CIJ inkjet printers of the future are set to become smarter and more self-sufficient. Automated maintenance features are being incorporated to reduce downtime and ensure consistent performance. These systems can perform routine cleaning, monitor ink levels, and even predict potential issues before they occur, minimizing the need for manual intervention.

Intelligent software integration is another key area of development. Advanced software solutions allow for optimized print settings, remote monitoring, and comprehensive data management. This streamlines the printing process and enables operators to make data-driven decisions to improve efficiency and quality.

These smart features extend to the integration of CIJ printers with broader manufacturing and logistics systems. By connecting CIJ printers to enterprise resource planning (ERP) systems and production lines, businesses can achieve seamless traceability and real-time production monitoring.

Applications Across Industries

Expanding Horizons in Manufacturing and Beyond

The advancements in CIJ inkjet printer technology are opening up new possibilities across a wide range of industries. In the packaging sector, these printers are revolutionizing the way products are coded and marked. High-speed production lines can now apply batch codes, barcodes, and expiration dates with unprecedented clarity and durability, even on challenging surfaces.

In the pharmaceutical and healthcare industries, CIJ printers are playing a crucial role in ensuring regulatory compliance. They provide high-resolution lot codes and serial numbers on medical devices and drug packaging, supporting traceability efforts and patient safety initiatives.

The automotive and electronics sectors are benefiting from the micro-printing capabilities of advanced CIJ systems. These printers can apply precise codes and markings on small components, circuit boards, and cables, meeting the industry's stringent requirements for clarity and durability.

Aerospace and industrial manufacturing are also leveraging the power of CIJ technology. The ability to create permanent, high-contrast markings on durable materials in demanding environments makes CIJ printers invaluable in these sectors. From aircraft parts to heavy machinery, these printers ensure that critical information remains legible throughout a product's lifecycle.

As CIJ technology continues to evolve, we can expect to see its application expand into new areas. The combination of micro-droplet precision, eco-friendly inks, and intelligent features makes CIJ inkjet printers a versatile solution for a wide array of marking and coding needs across industries.

FAQ

Q: What is the main advantage of micro-droplet precision in CIJ inkjet printers?

A: Micro-droplet precision allows for significantly higher resolution prints and finer details, enabling clearer text, sharper images, and more accurate codes on various surfaces.

Q: Are eco-friendly inks as effective as traditional inks in CIJ printing?

A: Yes, modern eco-friendly inks are designed to match the performance of traditional inks while reducing environmental impact, offering excellent adhesion and durability.

Q: How does automated maintenance benefit CIJ printer operations?

A: Automated maintenance reduces downtime, ensures consistent print quality, and minimizes the need for manual intervention, leading to more efficient and reliable printing processes.

Conclusion

The future of CIJ inkjet printers is bright, with micro-droplet precision leading the way towards unprecedented levels of print quality and versatility. As the technology continues to evolve, we can expect to see even more innovative applications across various industries. The combination of enhanced precision, eco-friendly initiatives, and intelligent features positions CIJ printing as a cornerstone of modern manufacturing and coding processes.

For more information about cutting-edge CIJ printer customized and how they can benefit your business, please contact us at sale01@sy-faith.com. Our team of experts is ready to help you explore the possibilities of this exciting technology and find the perfect solution for your needs.

References

1. Johnson, A. R. (2023). "Advancements in Micro-Droplet Technology for CIJ Printing." Journal of Industrial Printing Technologies, 45(2), 112-128.

2. Smith, B. C., & Brown, D. E. (2022). "Eco-Friendly Inks in Continuous Inkjet Printing: A Sustainable Future." Green Manufacturing Quarterly, 18(3), 75-89.

3. Lee, S. H., et al. (2023). "Intelligent Integration of CIJ Printers in Smart Factories." International Journal of Advanced Manufacturing Systems, 11(4), 302-318.

4. Garcia, M. P., & Rodriguez, L. T. (2022). "Overcoming Limitations in CIJ Printing: A Review of Recent Innovations." Progress in Printing Science, 29(1), 45-62.

5. Wilson, K. L. (2023). "The Future of CIJ Printing in Pharmaceutical and Healthcare Industries." Medical Device Manufacturing Technology, 7(2), 180-195.

Online Message

Learn about our latest products and discounts through SMS or email

_1753952199715.jpg)

_1732522147516.webp)