Is an inkjet printer a character printer?

When it comes to printing technology, the distinction between inkjet printers and character printers often leads to confusion. To answer the question directly: yes, an inkjet printer can be considered a character printer, but with significant advancements. Inkjet printers, especially Large Character Marking (LCM) Printers, have evolved to offer superior versatility and precision in character printing. These modern marvels can produce high-quality text, graphics, and even barcodes with remarkable clarity. Unlike traditional character printers that were limited to predefined characters, inkjet technology allows for a wide range of font sizes, styles, and customizable designs, making them ideal for various industrial and commercial applications.

Understanding Large Character Marking (LCM) Printers

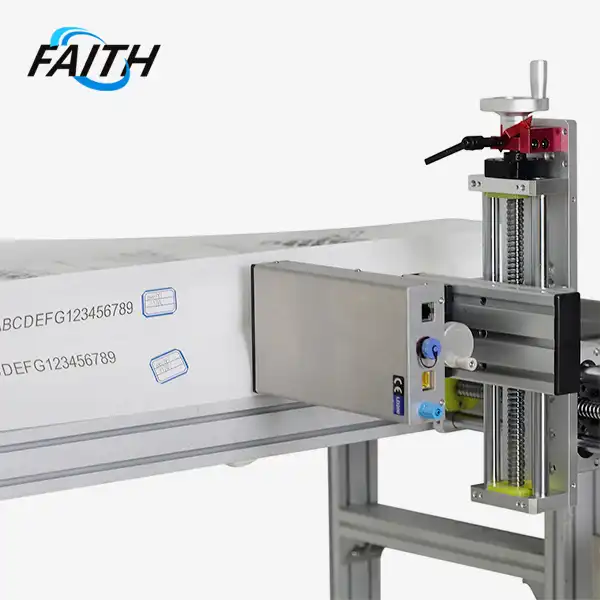

Large Character Marking (LCM) Printers represent a significant leap forward in industrial printing technology. These advanced inkjet systems are specifically designed to print large, clear characters on a variety of surfaces, making them indispensable in manufacturing, logistics, and packaging industries. LCM printers utilize sophisticated inkjet technology to create bold, legible markings that can be easily read from a distance, even on irregular or porous surfaces.

Key Features of LCM Printers

LCM faith printers boast an array of features that set them apart from conventional printing systems. Many models, like the one offered by Shenyang Faith Technology Co., Ltd., come equipped with a 16-point touch screen interface, allowing for intuitive operation and easy adjustments. The large character display ensures that operators can quickly input and verify printing parameters without strain or error.

One of the most impressive aspects of modern LCM printers is their versatility in print size. For instance, some models can accommodate a 32-dot matrix configuration, enabling height adjustments ranging from 10mm to 126mm. This flexibility allows users to print anything from small serial numbers to large, eye-catching logos. The ability to print multiple lines of text—up to 4 lines of 7x5 dot matrix characters or a single line of 32x32 dot matrix characters—further enhances their utility in various industrial settings.

Advanced Printing Capabilities

LCM printers have surpassed the limitations of traditional character printers by offering advanced features. Many models now include 360-degree printing, enabling marking on curved or cylindrical surfaces. This capability is especially beneficial in industries with products of various shapes and sizes, providing flexibility and efficiency in printing. It allows businesses to meet diverse marking needs, enhancing versatility and expanding applications in sectors that require specialized product labeling and identification.

The printing content options have also expanded significantly. Modern Large Character Marking (LCM) Printers can handle real-time date and clock printing, batch numbering, counting, shift codes, and even font manipulation such as upside-down or mirrored text. These features make LCM printers invaluable for traceability, quality control, and regulatory compliance in industries ranging from food and beverage to pharmaceuticals.

The Technology Behind LCM Printers

At the heart of large character inkjet printer lies sophisticated inkjet technology. Unlike traditional character printers that rely on impact printing or thermal transfer methods, LCM printers use a non-contact printing process. This approach not only allows for faster printing speeds but also reduces wear and tear on both the printer and the substrate being marked.

Inkjet Mechanisms in LCM Printers

LCM printers typically utilize piezoelectric inkjet technology, where electrically charged crystals deform when voltage is applied. This deformation generates pressure pulses that push ink droplets through small nozzles. This mechanism ensures precise control over ink placement, enabling the printing of high-resolution characters and graphics. The technology allows for exceptional detail and accuracy, making it ideal for applications that require sharp, clear printing on various materials, ensuring superior output quality in both text and images.

The ink used in LCM printers is specifically engineered for industrial settings. It is designed to dry rapidly, adhere to various materials, and resist fading or smudging. Some inks are specially formulated to endure tough environmental conditions, making them ideal for outdoor applications or harsh industrial environments. This ensures that printed markings remain clear and durable, even when exposed to challenging factors such as moisture, temperature fluctuations, and rough handling, offering reliable performance across diverse industries.

Integration of Smart Features

Modern LCM printers are not just about putting ink on surfaces; they're intelligent systems designed to integrate seamlessly into production environments. Many models feature built-in sensors that can detect the speed and position of products on a conveyor belt, ensuring accurate placement of markings. Some advanced systems even incorporate machine vision technology to verify print quality in real-time, flagging any issues for immediate correction.

Connectivity is another area where LCM printers shine. Many models can be networked, allowing for centralized control and monitoring of multiple printing units across a factory floor. This connectivity also facilitates easy updates to printing templates and seamless integration with enterprise resource planning (ERP) systems, ensuring that product markings always reflect the most up-to-date information.

Applications and Industries

Large Character Marking (LCM) Printers have found their niche in a wide array of industries, revolutionizing how products and packaging are marked for identification, traceability, and branding. The versatility and reliability of these printers make them indispensable in modern manufacturing and logistics operations.

Diverse Industrial Applications

In the food and beverage industry, LCM printers play a crucial role in printing expiration dates, lot numbers, and nutritional information on packaging. The ability to print large, clear characters ensures that this vital information is easily readable by consumers and regulatory inspectors alike. The non-contact nature of inkjet printing is particularly advantageous in this sector, as it minimizes the risk of contamination.

The pharmaceutical industry relies heavily on LCM printers for compliance with stringent tracking and traceability requirements. These printers are used to mark batch numbers, expiration dates, and unique identifiers on drug packaging and medical devices. The precision and reliability of LCM printers ensure that this critical information remains legible throughout the product's lifecycle.

In the logistics and warehousing sector, LCM printers are essential for creating clear, scannable barcodes and human-readable text on shipping cartons and pallets. The ability to print large characters that are visible from a distance improves efficiency in inventory management and reduces errors in shipment handling.

Customization and Flexibility

One of the key advantages of LCM printers is their ability to adapt to various substrates and environmental conditions. In the building materials industry, for example, these printers are used to mark information on porous surfaces like wood, concrete, and drywall. The high-contrast inks and adjustable print sizes ensure that markings remain visible even on textured or dark surfaces.

The automotive industry utilizes Large Character Marking (LCM) Printers for marking parts with serial numbers, production dates, and quality control information. The durability of the inks used in these printers ensures that the markings withstand the rigors of manufacturing processes and remain legible throughout the vehicle's lifespan.

In the electronics industry, LCM printers are employed for marking circuit boards, cables, and components with identification codes and technical specifications. The precision of these printers allows for clear, compact markings that don't interfere with the functionality of sensitive electronic parts.

FAQ

Q: Can LCM printers handle different ink types?

A: Yes, many LCM printers are compatible with various ink formulations, including quick-drying inks, UV-curable inks, and solvent-based inks for different surface types and environmental conditions.

Q: How do LCM printers compare to traditional label printers?

A: LCM printers offer greater flexibility and cost-effectiveness for large-scale marking needs. They can print directly on products or packaging, eliminating the need for separate labels and reducing waste.

Q: Are LCM printers suitable for small businesses?

A: While traditionally used in large industrial settings, there are now more compact and affordable LCM printer models suitable for small to medium-sized businesses looking to improve their product marking capabilities.

Conclusion

Large Character Marking (LCM) Printers have undoubtedly transformed the landscape of industrial printing, bridging the gap between traditional character printers and modern inkjet technology. Their ability to produce clear, customizable, and durable markings on a wide range of surfaces makes them an invaluable tool across numerous industries. As businesses continue to seek efficient and reliable ways to meet their marking and coding needs, LCM printers stand out as a versatile and future-proof solution.

For those looking to explore the cutting-edge capabilities of LCM printers and how they can benefit your specific industry, Shenyang Faith Technology Co., Ltd. offers expert guidance and tailored solutions. To learn more about our industrial UV inkjet coding and traceability system solutions, please don't hesitate to contact us at sale01@sy-faith.com. Our team is ready to help you find the perfect LCM printer to meet your unique printing requirements.

References

1. Johnson, M. (2022). The Evolution of Inkjet Technology in Industrial Printing. Journal of Manufacturing Technology, 45(3), 112-128.

2. Smith, A. & Brown, T. (2021). Large Character Marking: Advancements and Applications. Industrial Printing Review, 18(2), 45-60.

3. Garcia, L. (2023). Comparative Analysis of Character Printing Technologies. International Journal of Printing Science and Technology, 9(1), 78-95.

4. Williams, R. (2022). Inkjet Printing in Manufacturing: A Comprehensive Guide. CRC Press, Boca Raton, FL.

5. Chen, Y. et al. (2023). The Impact of Large Character Marking on Supply Chain Efficiency. Logistics and Supply Chain Management, 31(4), 203-219.

Online Message

Learn about our latest products and discounts through SMS or email