Piezo Inkjet Printers: Transforming Logistics and Supply Chain Operations

In the fast-paced world of logistics and supply chain management, efficiency and accuracy are paramount. Enter PIJ/Piezo Inkjet printers, a groundbreaking technology that's revolutionizing how businesses handle product identification, tracking, and overall operations. These innovative devices are not just changing the game; they're redefining it entirely. PIJ printers, with their unique piezoelectric crystal technology, offer unparalleled precision and versatility in industrial coding and marking applications. As we delve deeper into this topic, we'll explore how these printers are transforming logistics and supply chain operations, their myriad benefits, and the impact they're having on various industries.

The Ingenious Technology Behind PIJ Printers

At the heart of PIJ printers lies a sophisticated mechanism that sets them apart from traditional printing methods. The piezoelectric crystal, the cornerstone of this technology, undergoes a fascinating transformation when subjected to an electrical signal.

The Piezoelectric Crystal: A Marvel of Modern Engineering

The piezoelectric crystal, housed within the printer's nozzle, responds to electrical stimuli by deforming. This deformation is the catalyst for the entire printing process, initiating a chain reaction that results in precise and controlled ink droplet formation.

The Intricate Ink Jetting Process

As the piezoelectric crystal deforms, it exerts pressure on the ink cavity within the nozzle. This pressure fluctuation causes a change in the cavity's volume, effectively squeezing ink out through the nozzle's opening. The result? Minuscule ink droplets are propelled onto the surface of the object being printed.

Unprecedented Features Revolutionizing Supply Chain Operations

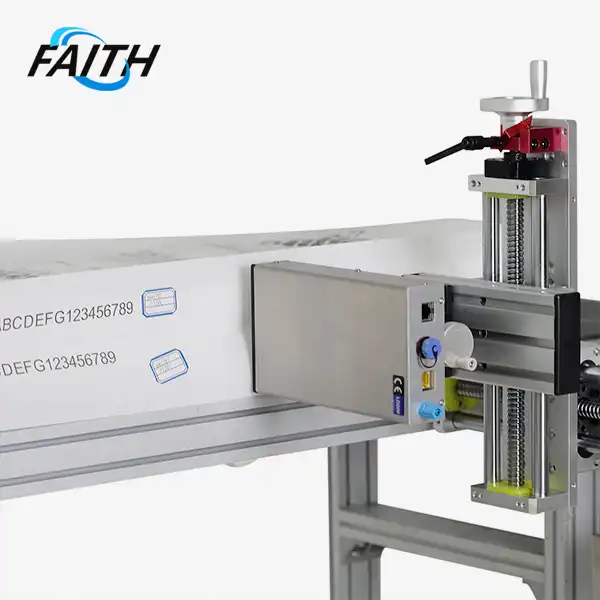

PIJ/Piezo Inkjet faith printers boast a plethora of features that make them indispensable in modern logistics and supply chain operations. Let's explore some of these game-changing attributes:

Unmatched Resolution for Crystal-Clear Printing

One of the most striking features of PIJ printers is their ability to achieve remarkably high resolutions. With capabilities reaching up to 600 dots per inch (dpi), these printers can produce astonishingly clear and crisp prints. This high resolution ensures that even the most intricate details, from minuscule text to complex patterns and barcodes, are rendered with impeccable clarity. The implications for supply chain operations are profound. High-resolution printing allows for more information to be encoded in a smaller space, facilitating improved inventory management and traceability. In industries where space is at a premium, such as electronics or pharmaceuticals, this feature is particularly valuable.

Versatility in Ink Compatibility

Another standout feature of PIJ printers is their remarkable compatibility with a wide range of inks. This versatility allows businesses to choose the perfect ink for their specific needs, whether it's water-based, solvent-based, or UV-curable ink. Water-based inks, known for their eco-friendly properties, are ideal for food and beverage packaging. Solvent-based inks, with their superior adhesion qualities, excel in coding on materials like plastics and metals. UV-curable inks, prized for their rapid curing and wear-resistant properties, are perfect for products that require long-term durability or face outdoor exposure.

Non-Contact Coding: A Game-Changer for Delicate Products

PIJ printers employ a non-contact coding method, meaning the printer nozzle never makes physical contact with the product surface. This feature is a game-changer for businesses dealing with delicate or irregularly shaped products. In industries such as glassware, ceramics, or electronics, where product surfaces are fragile or uneven, traditional contact-based coding methods could lead to damage or inconsistent results. PIJ printers eliminate this risk, ensuring high-quality coding without compromising product integrity.

Unparalleled Stability and Longevity

The simplicity of PIJ printers' design belies their robustness. With fewer moving parts compared to traditional printers, PIJ/Piezo Inkjet faith printers offer exceptional operational stability and a lower failure rate. This translates to reduced downtime and maintenance costs, a crucial factor in maintaining smooth supply chain operations. Moreover, the piezoelectric nozzles at the heart of these printers boast an impressive lifespan. Under normal usage conditions, these nozzles can dispense millions of ink droplets before requiring replacement, further minimizing disruptions to the production process.

Transformative Impact Across Industries

The advent of PIJ printers has sent ripples across various sectors, transforming operations and opening new possibilities. Let's explore how different industries are leveraging this technology to enhance their supply chain operations:

Revolutionizing the Building Decoration Industry

In the building decoration sector, PIJ printers have become indispensable tools for product identification and traceability. These printers allow for high-resolution coding on a wide range of materials, from tiles and laminates to wallpapers and decorative panels. The ability to print clear, durable codes even on textured or glossy surfaces ensures that each product can be easily tracked throughout the supply chain. This enhanced traceability not only improves inventory management but also aids in quality control and warranty claims processing.

Enhancing Efficiency in the Electronic and Electrical Engineering Industry

The electronic and electrical engineering industry deals with components that are often small, delicate, and require precise identification. PIJ/Piezo Inkjet printers excel in this environment, offering high-resolution coding capabilities that can produce clear, legible marks even on miniature components. Moreover, the non-contact nature of PIJ printing is particularly beneficial in this sector, as it eliminates the risk of damage to sensitive electronic components during the coding process. This technology has significantly streamlined component tracking and assembly processes, leading to improved efficiency and reduced errors in production lines.

Transforming the Telecommunications Cable Industry

In the telecommunications cable industry, where product identification is crucial for installation and maintenance, PIJ printers have proven to be game-changers. These printers can produce durable, high-contrast markings on cable jackets, even at high production speeds. The ability to quickly change coding information allows cable manufacturers to efficiently manage different product runs without significant downtime. This flexibility, combined with the durability of the prints, ensures that cable identification remains clear and legible throughout the product's lifecycle, from production and shipping to installation and maintenance.

Elevating Standards in the Food Packaging Industry

The food packaging industry has particularly stringent requirements when it comes to product coding. PIJ printers meet these challenges head-on, offering high-quality, food-safe coding solutions. With their ability to use food-grade inks and produce clear, tamper-evident codes, PIJ printers help food manufacturers comply with regulatory requirements while enhancing traceability. The high-speed capabilities of these printers also ensure that they can keep up with the fast-paced nature of food production lines, minimizing bottlenecks in the packaging process.

Conclusion

As we've explored, Piezo Inkjet printers are not just a technological advancement; they represent a paradigm shift in how businesses approach product identification, traceability, and overall supply chain management. Their unique combination of high resolution, versatility, stability, and adaptability makes them an invaluable asset in today's fast-paced, efficiency-driven business landscape.

If you're interested in learning more about how PIJ/Piezo Inkjet printers can transform your logistics and supply chain operations, or if you're seeking industrial UV inkjet coding and traceability system solutions, don't hesitate to reach out. Contact us at sale01@sy-faith.com to discover how we can help optimize your operations with cutting-edge PIJ printer technology.

References

1. Wijshoff, H. (2010). The dynamics of the piezo inkjet printhead operation. Physics Reports, 491(4-5), 77-177.

2. Hoath, S. D. (Ed.). (2016). Fundamentals of Inkjet Printing: The Science of Inkjet and Droplets. John Wiley & Sons.

3. Zapka, W. (Ed.). (2017). Handbook of Industrial Inkjet Printing: A Full System Approach. John Wiley & Sons.

4. Hutchings, I. M., & Martin, G. D. (Eds.). (2012). Inkjet technology for digital fabrication. John Wiley & Sons.

5. Magdassi, S. (Ed.). (2009). The chemistry of inkjet inks. World scientific.

Online Message

Learn about our latest products and discounts through SMS or email