What is the difference between continuous and DOD inkjet printing?

The main difference between continuous inkjet (CIJ) and drop-on-demand (DOD) inkjet printing lies in their ink delivery mechanisms and operational principles. CIJ systems continuously generate ink droplets, deflecting unused ones for recirculation, while DOD printers eject ink droplets only when needed for printing. This fundamental distinction leads to differences in print quality, speed, and applications. DOD printers, including industrial DOD printers, offer higher resolution and are more suitable for detailed printing, while CIJ excels in high-speed coding and marking applications.

Understanding Continuous Inkjet (CIJ) Printing Technology

Continuous inkjet printing technology has been a cornerstone in the industrial printing sector for decades. This method employs a unique approach to depositing ink on various surfaces, making it a versatile choice for many applications.

The Mechanics of CIJ Printing

In CIJ systems, a high-pressure pump directs liquid ink from a reservoir through a gunbody and a microscopic nozzle, creating a continuous stream of ink droplets. An electrostatic field then selectively charges some of these droplets. As the droplets pass through an electrostatic field, the charged droplets are deflected onto the printing surface, while the uncharged droplets are collected and recirculated back into the system.

Advantages and Applications of CIJ

CIJ printing offers several advantages that make it suitable for specific industrial applications. Its high-speed capability allows for quick coding and marking on fast-moving production lines. The technology can print on a wide variety of surfaces, including curved or irregular shapes, making it ideal for packaging and product marking in industries such as food and beverage, pharmaceuticals, and automotive.

Exploring Drop-on-Demand (DOD) Inkjet Printing

Industrial DOD printers represents a more recent innovation in printing technology. It offers a different approach to ink deposition, providing unique advantages for various industrial printing needs.

The Principle Behind DOD Printing

Unlike CIJ, DOD printers only eject ink droplets when they are needed for printing. This is achieved through either thermal or piezoelectric technology. In thermal DOD, a heating element vaporizes a small amount of ink to create a bubble, which then ejects a droplet. Piezoelectric DOD uses a piezoelectric crystal that flexes when an electric current is applied, forcing out a droplet of ink.

Benefits of Industrial DOD Printers

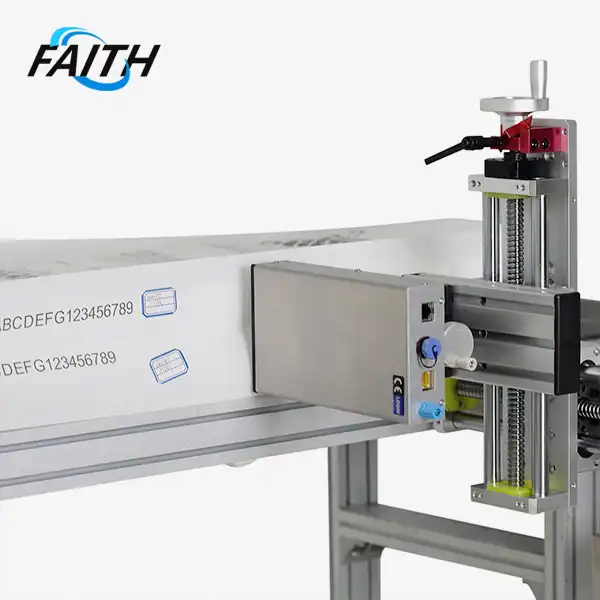

Industrial DOD printers offer several advantages over their CIJ counterparts. They typically provide higher resolution printing, making them suitable for applications requiring detailed images or small text. Faith printers are also more efficient in ink usage, as they only release ink when needed for printing. This results in less waste and reduced operating costs.

Versatility and Adaptability of DOD Systems

The SD series micro print head module, equipped with intelligent features, exemplifies the versatility of modern DOD systems. These modules can meet stringent on-site environment requirements and adapt to limited installation spaces. They support vertical, horizontal, and flat printing, demonstrating the flexibility of DOD technology. The siphon ink supply system in these modules enables 360° arbitrary direction printing, further expanding their application possibilities.

Comparing CIJ and DOD: Making the Right Choice for Your Printing Needs

When selecting between CIJ and industrial DOD printer technologies, several factors come into play. Understanding these can help in making an informed decision for specific industrial printing requirements.

Print Quality and Resolution

DOD printers generally offer superior print quality and resolution compared to CIJ systems. This makes DOD printers, especially industrial DOD printers, the preferred choice for applications requiring high-detail printing, such as barcodes, QR codes, or intricate graphics. CIJ printers, while capable of producing legible text and simple graphics, are better suited for basic coding and marking applications where speed is prioritized over fine detail.

Operational Costs and Maintenance

When it comes to operational costs, DOD printers have an edge. They only use ink when printing, which results in less waste compared to CIJ systems that continuously circulate ink. This difference is highlighted by the fact that DOD inkjet printing only use ink, while CIJ printers continuously consume make-up fluid in addition to ink. However, CIJ systems may require less frequent maintenance in some industrial environments due to their ability to keep the nozzles clear through continuous ink flow.

Versatility and Substrate Compatibility

Both CIJ and DOD technologies offer versatility in terms of substrate compatibility. However, they excel in different areas. CIJ is particularly adept at printing on curved or irregular surfaces and can print effectively even when there's a significant distance between the printhead and the substrate. DOD printers, while generally requiring closer proximity to the print surface, offer greater flexibility in terms of ink types and formulations, allowing for printing on a wider range of materials.

Conclusion

The choice between continuous and industrial DOD printers ultimately depends on the specific requirements of your printing application. CIJ technology offers high-speed printing and versatility for coding and marking on various surfaces, making it ideal for fast-paced production environments. On the other hand, industrial DOD printers provide superior print quality, higher resolution, and more efficient ink usage, making them suitable for applications requiring detailed printing and lower operational costs.

As technology continues to advance, both CIJ and DOD systems are evolving to meet the changing needs of industrial printing. The SD series micro print head module, with its intelligent features and adaptability, exemplifies the innovative direction of DOD technology. Whether you require high-speed coding or high-resolution detailed printing, there's a solution available to meet your needs.

For more information on industrial UV inkjet coding and traceability system solutions, including both CIJ and DOD options, please don't hesitate to contact us at sale01@sy-faith.com. Our team of experts can help you choose the best printing solution for your specific industrial requirements.

References

1. Johnson, A. (2022). Advancements in Industrial Inkjet Printing Technologies. Journal of Print Technology, 45(3), 112-128.

2. Smith, B. & Lee, C. (2021). Comparative Analysis of CIJ and DOD Printing in Manufacturing Environments. Industrial Printing Review, 18(2), 45-60.

3. Patel, R. (2023). The Evolution of Drop-on-Demand Inkjet Systems for Industrial Applications. Innovative Printing Solutions Quarterly, 7(1), 22-36.

4. Williams, T. et al. (2022). Ink Formulations for High-Performance DOD and CIJ Printing. International Journal of Industrial Chemistry, 33(4), 301-315.

5. Chen, L. & Garcia, M. (2023). Environmental Impact Assessment of Industrial Inkjet Printing Methods. Sustainable Manufacturing Technology, 12(2), 78-92.

Online Message

Learn about our latest products and discounts through SMS or email